I do not understand what you are asking. Time, effort, and some money?What do you have invested in it so far?

Upvote 0

I do not understand what you are asking. Time, effort, and some money?What do you have invested in it so far?

I was thinking more in terms of money. I can't begin to imagine the time and effort it took. It's genius though so it's well worth it.I do not understand what you are asking. Time, effort, and some money?

18gr .02gr <--- 0.001% this is not realistic, it is beyond the capability of this machineThat means the machine can weigh for example an 18 grain pellet to a tolerance of 0.02 grain?

Money-wise, not much because I have most of the stuff lying around the shop. It's just plastic & wood & some aluminum & some .....I was thinking more in terms of money. I can't begin to imagine the time and effort it took. It's genius though so it's well worth it.

That is truly epic and what a cool machineMoney-wise, not much because I have most of the stuff lying around the shop. It's just plastic & wood & some aluminum & some .....

Time:

Thinking of the concept, how to arrange the parts, layout, etc.... took more than 2 months of hand-waving while alone by myself

Fabrication took about 2 weeks (CNC programming too)

Software coding about 1 week

Debug plus revisions took 3 weeks, still on-going with some possible(?) improvements

Effort: a little elbow grease, which is much needed in my ageing joints (65yo ATM). I am also happy to see that I can still write SW and perform debug.

This is system noise. It even goes up to +0.08gr sometimes. I have ordered a low noise version of the weighing scale amplifier and hopefully this variation in the readings will go away once the new amplifier is installed.....the lowest I saw was -0.04gr but there also was a 0.00 so I guess it goes down to 0.01gr differences at least.

Maybe I'm making a mistake, but 0.1% of 18 grains is 0.018 grains, rounded up to 0.02 grains. And 0.1% was the tolerance claim.18gr .02gr <--- 0.001% this is not realistic, it is beyond the capability of this machine

There will always be some residual noise in any measurement system. I can filter it out by averaging but that will consume a lot of time and slow the process down. I am still looking out for a better weighing system but this is what I have at the moment.

The Test Limits are computed this way. For an 18 grain pellet with a tolerance of +/-1%, the Bin assignments and corresponding weight limits are like this:

View attachment 567846

Notice that pellets with typical weights are assigned to Bin 3. The pellets in that bin will weigh anywhere in between 17.82 ~ 18.18 grains. In this chart you can also see the weights of the pellets in the other bins.

If the Tolerance is changed to 2%, the Bin assignments and weights will look like this:

View attachment 567847

Notice that Bin 3 still holds pellets with typical weights but now they will weigh anywhere in between 17.64 ~ 18.36 grains.

H&N the pellet manufacturer! Would be interesting to see how much spread there is in your manufacturing process. Or perhaps further down the road you can put a sticker on your tins showing the range of pellet weights that is inside the tin. (We used to do this kind of "grading" on semiconductors. Still done today but since commercial parts dominate the market now, grading is seldom done.)

You are correct, my bad. I got confused with so many zeroes.Maybe I'm making a mistake, but 0.1% of 18 grains is 0.018 grains, rounded up to 0.02 grains. And 0.1% was the tolerance claim.

1% tolerance, plus or minus, is already a 2% range. That would actually be too much for an H&N production batch.

Yes it can be built to order. I sent you a message with more details.Is a machine like that available/planned to be available to members?

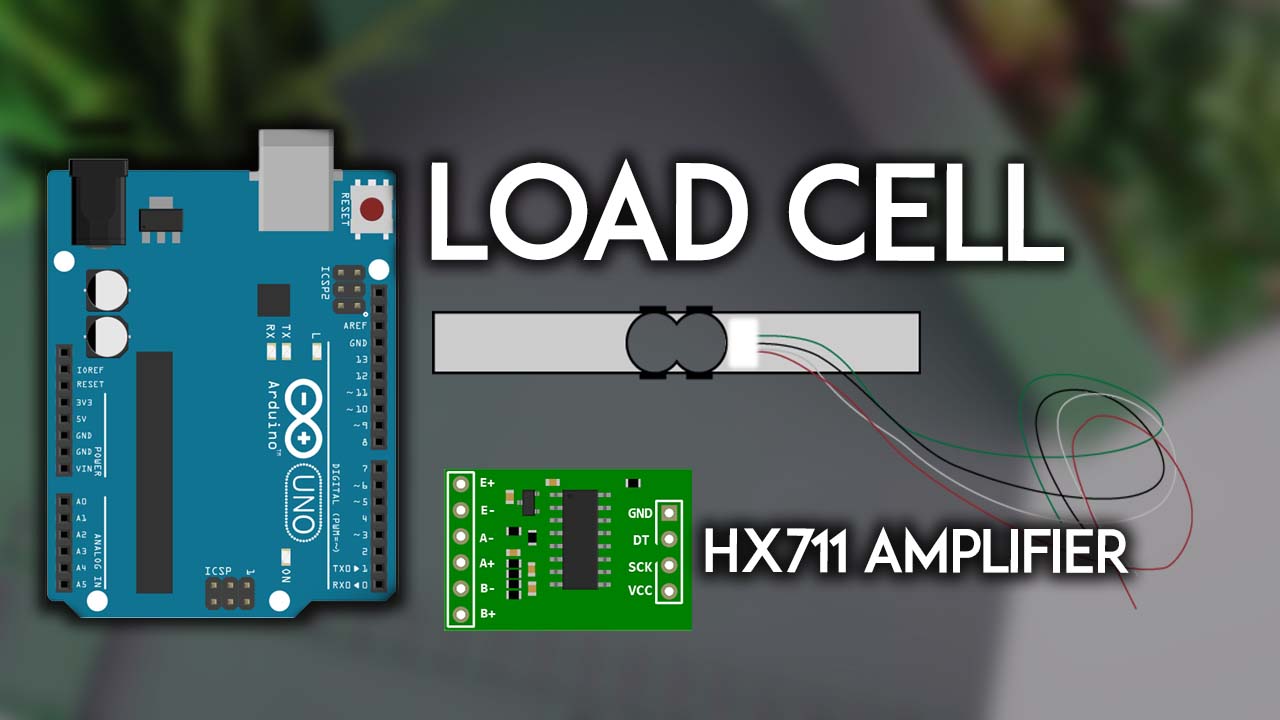

HX711Mind you telling me what weight scale and amplifier you using?

I just got retired recently and this your project seem to me a good entertainment to start with

HX711

Google is your friendcan you say it in little more details?

What is a load cell and where to get it? I assume aliexpress?