You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mounting Holosun 507c Reflex Sight on Huben GK1 - Sight In (Issues and Resolution)

- Thread starter Ezana4CE

- Start date

On another pistol but I had two adapter plates that were very nearly the same but different enough so my Holosun only fit one exactly.

The other one left the RD cocked up too high and lopsided but it was hard to tell without looking closer.

I think I had to order the correct one separately but I can't quite remember.

The other one left the RD cocked up too high and lopsided but it was hard to tell without looking closer.

I think I had to order the correct one separately but I can't quite remember.

Upvote 0

@steve123 That's one thing I'd like to try is swapping plates. The other thing I'm unsure about is the mounting screw. Are y'all using the same factory screw that holds the rear sight in to mount your base plates? Then the torque specs. I may have it tamped down too tight.On another pistol but I had two adapter plates that were very nearly the same but different enough so my Holosun only fit one exactly.

The other one left the RD cocked up too high and lopsided but it was hard to tell without looking closer.

I think I had to order the correct one separately but I can't quite remember.

Upvote 0

I am using the factory screw. Things need to be locked in place, but not too tight. I noticed that tightening too much seems to lift the front of the sight upward. Really ought to be a little spacer where the rear sight was.@steve123 That's one thing I'd like to try is swapping plates. The other thing I'm unsure about is the mounting screw. Are y'all using the same factory screw that holds the rear sight in to mount your base plates? Then the torque specs. I may have it tamped down too tight.

Upvote 0

@WobblyHand This is exactly what I did and it’s what I suspected was the root of the problem. Thanks for mentioning it. I’ll post pics later.I am using the factory screw. Things need to be locked in place, but not too tight. I noticed that tightening too much seems to lift the front of the sight upward. Really ought to be a little spacer where the rear sight was.

Upvote 0

The uneven space between the gap was what I suspected was the issue.

Even after I loosened the mounting screw that affixes the base plate I still see an uneven gap.

Even after I loosened the mounting screw that affixes the base plate I still see an uneven gap.

Upvote 0

As you noticed, that isn't going to work well. Front of the sight is pointing to the sky! Need to fix that somehow. Maybe some sort of spacer in the former rear sight cavity, to make it level with the edges?The uneven space between the gap was what I suspected was the issue.

View attachment 566811

Even after I loosened the mounting screw that affixes the base plate I still see an uneven gap.

View attachment 566812

The sight base I have sits flat on the top of the receiver, but if you reef on the rear screw the front of the sight base will lift a tiny bit. That lift means you run out of sight adjustment range way too early.

Upvote 0

@WobblyHand Thanks for the input. This is what I suspected all along. Although the angle is slight, I figured that’s what was causing it. I was just surprised it happened as close as 10 yards. Thankfully I bought a couple of plates. I was thinking of measuring the thickness of the plate with calipers to see if the machining of the plate causes a variance in thickness across the ends and the middle. Or maybe it’s just how the mounting hole was drilled. I was also thinking that I may need to try a different type of mounting screw. What are your thoughts here?As you noticed, that isn't going to work well. Front of the sight is pointing to the sky! Need to fix that somehow. Maybe some sort of spacer in the former rear sight cavity, to make it level with the edges?

The sight base I have sits flat on the top of the receiver, but if you reef on the rear screw the front of the sight base will lift a tiny bit. That lift means you run out of sight adjustment range way too early.

If it’s the machining on the gun’s receiver, it’s going back under warranty.

Last edited:

Upvote 0

From here, I can't determine it definitively. Need to measure the plates, the screw lengths, and the flatness of the receiver. These sight adapters rely on the "flatness" of the receiver. @M0ist0ne 's as well as everyone else's. Mine rests on the receiver along the entire length of the sight. I notice yours depends only on the back part of the receiver.@WobblyHand Thanks for the input. This is what I suspected all along. Although the angle is slight, I figured that’s what was causing it. I was just surprised it happened as close as 10 yards. Thankfully I bought a couple of plates. I was thinking of measuring the thickens or the plate with calipers to see if the machining of the plate cause a variance in thickness across the ends and the middle. Or maybe it’s just how the mounting hole was milled. I was also thinking that I may need to try a different type of mounting screw. What are your thoughts here?

If it’s the machining on the gun’s receiver, it’s going back under warranty.

That being said, I'd bet you might be able to make a spacer that fits in the rear sight cavity that has the right height to avoid this. It's just a small chunk of aluminum with a hole in it and filed to fit. Sure it's easier to make with machines, but easily doable with hand tools (a drill, a hacksaw and a file). Or just buy the same sight base as I did.

Keep us posted on this. My gut sense is the sight mount you have is depending on a surface that is not all that well controlled (from a mechanical sense). Still think a spacer hack will help you out. If you need a little chunk of aluminum to shape, let me know, I can easily come up with a scrap that's about the right size.

Upvote 0

@WobblyHand Thank you. When I was mounting the plate I found it odd to have it mounted by a single screw and the screw hole is situated towards the rear of the plate. Also, if I remember correctly, the screws that came with the plate don’t fit the rear sight screw hole atop the reciever. I’ll look into it further this evening.

Upvote 0

My sight base is only attached by a single screw to the receiver, but it seems to be ok, if snug but not tight. We both know it is best to tie a sight base down with two screws.@WobblyHand Thank you. When I was mounting the plate I found it odd to have it mounted by a single screw and the screw hole is situated towards the rear of the plate. Also, if I remember correctly, the screws that came with the plate don’t fit the rear sight screw hole atop the reciever. I’ll look into it further this evening.

I don't know about you, but I try not to mod things like that, if I don't have to. But I did mod my PP700SA receiver to capture the barrel nut. (Drilled and tapped for a pair of M3 set screws, one on each side.) There's a significant price difference between a GK1 and PP700-SA though... The tapped hole is at the "S" in Artemis.

I somewhat understand the GK1, but not yet enough to drill a (hopefully) blind hole and tap it. Dunno, might look into it. Would make it more stable.

Upvote 0

@WobblyHand Thank you. When I was mounting the plate I found it odd to have it mounted by a single screw and the screw hole is situated towards the rear of the plate. Also, if I remember correctly, the screws that came with the plate don’t fit the rear sight screw hole atop the reciever. I’ll look into it further this evening.

This is the screw I was talking about. I would think that a tapered flathead machine screw would fit nicely into this space. At least something that fits snug so there’s little room for movement.@WobblyHand Thanks for the input. This is what I suspected all along. Although the angle is slight, I figured that’s what was causing it. I was just surprised it happened as close as 10 yards. Thankfully I bought a couple of plates. I was thinking of measuring the thickens or the plate with calipers to see if the machining of the plate cause a variance in thickness across the ends and the middle. Or maybe it’s just how the mounting hole was milled. I was also thinking that I may need to try a different type of mounting screw. What are your thoughts here?

If it’s the machining on the gun’s receiver, it’s going back under warranty.

The plate came with two flat heads that are too large for the threaded (rear sight) hole on the receiver. Below the screw on the right is the GK1 stock rear sight screw. On the left is one of two flathead screws that fit almost perfectly within the rear hole on the base plate.

Here’s a photo of that flathead screw recessed nicely within the base plate (not mounted).

Now I need to find my other base plate To compare them, their screws, and fitment to the GK1 and Holosun sight.

Upvote 0

I’m trying to investigate this while watching my animals. What I have found is this - the base plates mate very well with the groove cutout for the GK1’s stock rear sight screw. The issue I’m facing arises when pressure is placed upon the rear of the reflex sight base plate. This pressure can come in the form of pressing down with my finger or slightly tightening the stock rear sight screw. This rearward pressure elevates the front of the base plate which in turn throws off the position of my optic interfering with my ability to zero it at short range. I’ll add more photos later.

What’s perplexing to me is how I’m having this issue, yet no other members with GK1s running ReddotMate base plates have documented this issue. If they have, I haven’t read about it. Anyone else encounter this?

What’s perplexing to me is how I’m having this issue, yet no other members with GK1s running ReddotMate base plates have documented this issue. If they have, I haven’t read about it. Anyone else encounter this?

Last edited:

Upvote 0

My GK1 rear sight used a flat head screw. I simply reused it.This is the screw I was talking about. I would think that a tapered flathead machine screw would fit nicely into this space. At least something that fits snug so there’s little room for movement.

View attachment 566877

The plate came with two flat heads that are too large for the threaded (rear sight) hole on the receiver. Below the screw on the right is the GK1 stock rear sight screw. On the left is one of two flathead screws that fit almost perfectly within the rear hole on the base plate.

View attachment 566880

Here’s a photo of that flathead screw recessed nicely within the base plate (not mounted).

View attachment 566881

Now I need to find my other base plate To compare them, their screws, and fitment to the GK1 and Holosun sight.

Is the bottom of the hole tapered at 90 degrees, or flat bottomed? If you use the socket head cap screw, is the top of the screw below the top of the hole? It should not protrude above the top surface. The photo seems to show that, but thought I'd ask to confirm.

Upvote 0

@WobblyHand Interesting. I’ll have to examine the hole again once I go inside to comment on its taper angle.My GK1 rear sight used a flat head screw. I simply reused it.

Is the bottom of the hole tapered at 90 degrees, or flat bottomed? If you use the socket head cap screw, is the top of the screw below the top of the hole? It should not protrude above the top surface. The photo seems to show that, but thought I'd ask to confirm.

Yes, the socket head screw is also recessed when tightened down.

Upvote 0

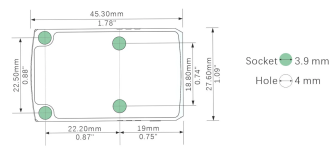

Nevermind, I went to the reddotmate website and looked up the adapter.My GK1 rear sight used a flat head screw. I simply reused it.

Is the bottom of the hole tapered at 90 degrees, or flat bottomed? If you use the socket head cap screw, is the top of the screw below the top of the hole? It should not protrude above the top surface. The photo seems to show that, but thought I'd ask to confirm.

You must have a gap between the bottom and the receiver. When you tighten the screw it bends the piece in the front upward. So either your receiver is deeper, or your reddotmate bottom piece is not as deep as it should be. You need to make a shim. First you need to measure the distance of the protrusion of the sight plate. You can use your caliper to do that. Then do the same thing with the receiver base. The difference between the measurements is the thickness of the shim you need.

Fun fact. An aluminum beer can, or soda pop can is 0.004" thick. You can cut up a can and make some layers if needed.

You don't use the little hole for the rear sight pin do you?

Last edited:

@WobblyHand You may have just solved the conundrum. I hadn’t even considered using the pin. I didn’t even check to see if there is a hole for it in the base plate. That would probably do the trick. Thanks so much for your input. That’s the first thing I’ll look for when I go inside. As for beer can shims, I have several that I can use if need be.Nevermind, I went to the reddotmate website and looked up the adapter.

View attachment 566895

You must have a gap between the bottom and the receiver. When you tighten the screw it bends the piece in the front upward. So either your receiver is deeper, or your reddotmate bottom piece is not as deep as it should be. You need to make a shim. First you need to measure the distance of the protrusion of the sight plate. You can use your caliper to do that. Then do the same thing with the receiver base. The difference between the measurements is the thickness of the shim you need.

Fun fact. An aluminum beer can, or soda pop can is 0.004" thick. You can cut up a can and make some layers if needed.

You don't use the little hole for the rear sight pin do you?

Upvote 0

Great attention to detail.Nevermind, I went to the reddotmate website and looked up the adapter.

View attachment 566895

…You don't use the little hole for the rear sight pin do you?

You are the man @WobblyHand!! May the airgun gods guide thy sights and steady thine grip so that thou aim is steady and thou projectiles flieth as straight as the javelins of Mars and Minerva.

I feel like an arse. smh. Although the instructions were vague as hell, I posted a screenshot of them in post #15. Looking back, they do mention “pins.” This mess is completely an oversight on my part. Thanks again.

Last edited:

Upvote 0

Oh, you are making me blush.Great attention to detail.

View attachment 566907

You are the man @WobblyHand!! May the airgun gods guide thy sights and steady thine grip so that thou aim is steady and thou projectiles flieth as straight as the javelins of Mars and Minerva.

I feel like and arse. smh. Although the instructions were vague as hell, I posted a screenshot of them in post #15. Looking back, they do mention “pins.” This mess is completely an oversight on my part. Thanks again.

Don't be harsh on yourself. We've all messed up on these kinds of things.

Like an idiot, I bought one of these cheap Pinty laser sights, the kind with 3 tiny LR41 batteries. I'm looking at it thinking, why the heck did I buy this POS? It's canted to the right. Left side is taller than the right side. Live and learn...

Anyways, glad I could help you!

Upvote 0

This may be overkill, but I photographed the steps I took to correct the issue. If you’ve never done this or have a brain fart, use this a reference guide for the ReddotMate mounting plate style #2 for the Huben GK1. Before doing anything, I rotated the magazine to be sure that the magazine was completely empty.

After removing the optic from the plate and the plate from the GK1 I laid out all of the parts and tools in the photo below.

Next I placed the reflex sight mounting plate into the groove that the rear sight sat in.

I then slid the plate forward, aligned the milled, recessed, screw hole in the plate with the threaded screw hole in the receiver, and placed the rear sight mounting screw in the hole.

Once I felt the screw grab the threads, I began tightening the screw to secure the mounting plate to the receiver with a torx driver. I tightened the screw to where I felt tension and backed offa couple of maybe a 1/2 turn.

My next task was to make sure that the 1mm pin holes in the mounting plate and the receiver were properly aligned. Seeing light through the hole was what I wanted to see.

After verifying proper alignment. I placed the 1mm rear sight hinge pin into the hole.

Next I tapped in the hinge pin. Once it got started it was easy to push in with a finger.

To be sure the pin was flush on both sides, I probed and pushed with this 1mm punch. It doesn’t take much effort at all. I just wanted it centered so that when I tightened the mounting screw, the elevation of the front of the plate would grab the pin and create enough tension to hold it taught so it won’t fall out easily.

I then gently, but firmly tightened the mounting screw. The slight gap created between the front of the mounting plate and the receiver doesn’t look as nearly as wide as before.

Now it’s time to affix the optic. Before I did that, I did my best to center the reticle. I clicked the elevation screw all the way down then back up and counted 72-73 clicks. I clicked back up and settled upon 72, 72/2 =36. I clicked up 36 clicks to center the reticle. After that, I sat the reflex sight onto the plate making sure that I felt the slightly protruding posts on the bottom fall into the holes on the mounting plate.

Then I placed the mounting screws in their holes.

Finally I snugged these two screws down to secure the optic. The remaining gap makes the bottom of the plate appear parallel to the receiver as opposed to sloped up like a ramp. I’ll attempt to zero it at 10 yards again tomorrow.

Below is a clear comparison of the gaps between the plate and receiver when mounted with and without the factory rear sight hinge pin. The top photo is with the 1mm hinge pin installed. The bottom photo is the mounting plate installed without the hinge pin.

After removing the optic from the plate and the plate from the GK1 I laid out all of the parts and tools in the photo below.

Next I placed the reflex sight mounting plate into the groove that the rear sight sat in.

I then slid the plate forward, aligned the milled, recessed, screw hole in the plate with the threaded screw hole in the receiver, and placed the rear sight mounting screw in the hole.

Once I felt the screw grab the threads, I began tightening the screw to secure the mounting plate to the receiver with a torx driver. I tightened the screw to where I felt tension and backed off

My next task was to make sure that the 1mm pin holes in the mounting plate and the receiver were properly aligned. Seeing light through the hole was what I wanted to see.

After verifying proper alignment. I placed the 1mm rear sight hinge pin into the hole.

Next I tapped in the hinge pin. Once it got started it was easy to push in with a finger.

To be sure the pin was flush on both sides, I probed and pushed with this 1mm punch. It doesn’t take much effort at all. I just wanted it centered so that when I tightened the mounting screw, the elevation of the front of the plate would grab the pin and create enough tension to hold it taught so it won’t fall out easily.

I then gently, but firmly tightened the mounting screw. The slight gap created between the front of the mounting plate and the receiver doesn’t look as nearly as wide as before.

Now it’s time to affix the optic. Before I did that, I did my best to center the reticle. I clicked the elevation screw all the way down then back up and counted 72-73 clicks. I clicked back up and settled upon 72, 72/2 =36. I clicked up 36 clicks to center the reticle. After that, I sat the reflex sight onto the plate making sure that I felt the slightly protruding posts on the bottom fall into the holes on the mounting plate.

Then I placed the mounting screws in their holes.

Finally I snugged these two screws down to secure the optic. The remaining gap makes the bottom of the plate appear parallel to the receiver as opposed to sloped up like a ramp. I’ll attempt to zero it at 10 yards again tomorrow.

Below is a clear comparison of the gaps between the plate and receiver when mounted with and without the factory rear sight hinge pin. The top photo is with the 1mm hinge pin installed. The bottom photo is the mounting plate installed without the hinge pin.

Last edited:

Upvote 0