You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

To glue your carbon fiber sleeve or not?

- Thread starter Milf Dots

- Start date

The sleeve does little, to no good of stiffening, if there's not a "tight" fit. If there's not full, intimant contact, it just looks pretty !

So...either -

1 - Bond it as close to 100% of the barrel surface as possible.

2 - Get a sleeve that will not slide over the barrel, (just by a couple of thousandths), then freeze the barrel overnight, then push the sleeve over the barrel.

Mike

So...either -

1 - Bond it as close to 100% of the barrel surface as possible.

2 - Get a sleeve that will not slide over the barrel, (just by a couple of thousandths), then freeze the barrel overnight, then push the sleeve over the barrel.

Mike

Upvote 0

Mine is a slip fit over the liner. Tight enough to stay in place, but not difficult to remove. Good enough to completely eliminate the occasional flyer so I left it that way.

Upvote 0

Isn’t the fiber sleeve to outer tube/barrel holder ( ) fit just as important and you certainly wouldn’t glue that. I don’t have one but I’d drop it in and let it rip. Steve’s Maverick video is enough convincing for me.

) fit just as important and you certainly wouldn’t glue that. I don’t have one but I’d drop it in and let it rip. Steve’s Maverick video is enough convincing for me.

Upvote 0

All of mine are glued. If it slips on and you don’t need a press, then your liner can still buzz or flex within the tube. If you can afford the gun we use these CF tubes on, you can afford multiple tubes for multiple liners. Don’t get cheap at this point. Lastly, if someone doesn’t need to glue the CF tube on, they may have never needed it in the first place. Can it help without glue? Why chance it and waste ammo. Because gluing it will never be worse than not gluing it. Unless you screw up and glue it on wrong.

Upvote 0

A couple of thousands will require a press to get it in, the CF sleeve will not expand, now maybe .0002" would do it, IF you could get it in.The sleeve does little, to no good of stiffening, if there's not a "tight" fit. If there's not full, intimant contact, it just looks pretty !

So...either -

1 - Bond it as close to 100% of the barrel surface as possible.

2 - Get a sleeve that will not slide over the barrel, (just by a couple of thousandths), then freeze the barrel overnight, then push the sleeve over the barrel.

Mike

Loctite may work or a REALLY thin epoxy (voice of experience, used some thick stuff, not a pretty scene with a mallet, nothing that requires air, some have used Silicon but it takes air and once the ends are sealed no more air inside. You need some working time so I'd stay away from super glue. Check out Ernst Rowe's video on it.What Brand of glue?

Upvote 0

Loctite 638 bearing compound is well suited to the task when the gap is under 0.010” (0.020” difference on the diameter). It produces a very strong bond and gives you plenty of working time.

Or use a 2-part epoxy if the gap is larger.

BTW if you don’t have an intuitive sense of how large a 0.010” to 0.020 gap is, it will seem very sloppy.

Or use a 2-part epoxy if the gap is larger.

BTW if you don’t have an intuitive sense of how large a 0.010” to 0.020 gap is, it will seem very sloppy.

Upvote 0

I have superlight barrels, so there is no retaining tube, liner free-floats on a set of spacers.Isn’t the fiber sleeve to outer tube/barrel holder () fit just as important and you certainly wouldn’t glue that. I don’t have one but I’d drop it in and let it rip. Steve’s Maverick video is enough convincing for me.

Chopped in half, epoxied both halves. Installed shroud while epoxy set up so it would all be centered when it hardened. Middle spacer is there for life unless it breaks, then would be replaced with a 3d printed one. Left some space at the rear for jamb nut to move. Has a deffinite affect on the gun. Much less picky about the tune or even ammo.

Last edited:

Upvote 0

This is what I used last night on 2-700mm liners. Perfect consistency for a good coating and bond, firmed up in 20 minutes and I’ll install them today.Loctite 638 bearing compound is well suited to the task when the gap is under 0.010” (0.020” difference on the diameter). It produces a very strong bond and gives you plenty of working time.

Or use a 2-part epoxy if the gap is larger.

BTW if you don’t have an intuitive sense of how large a 0.010” to 0.020 gap is, it will seem very sloppy.

Upvote 0

7 pieces of 20# paper, give or take.Loctite 638 bearing compound is well suited to the task when the gap is under 0.010” (0.020” difference on the diameter). It produces a very strong bond and gives you plenty of working time.

Or use a 2-part epoxy if the gap is larger.

BTW if you don’t have an intuitive sense of how large a 0.010” to 0.020 gap is, it will seem very sloppy.

Last edited:

Upvote 0

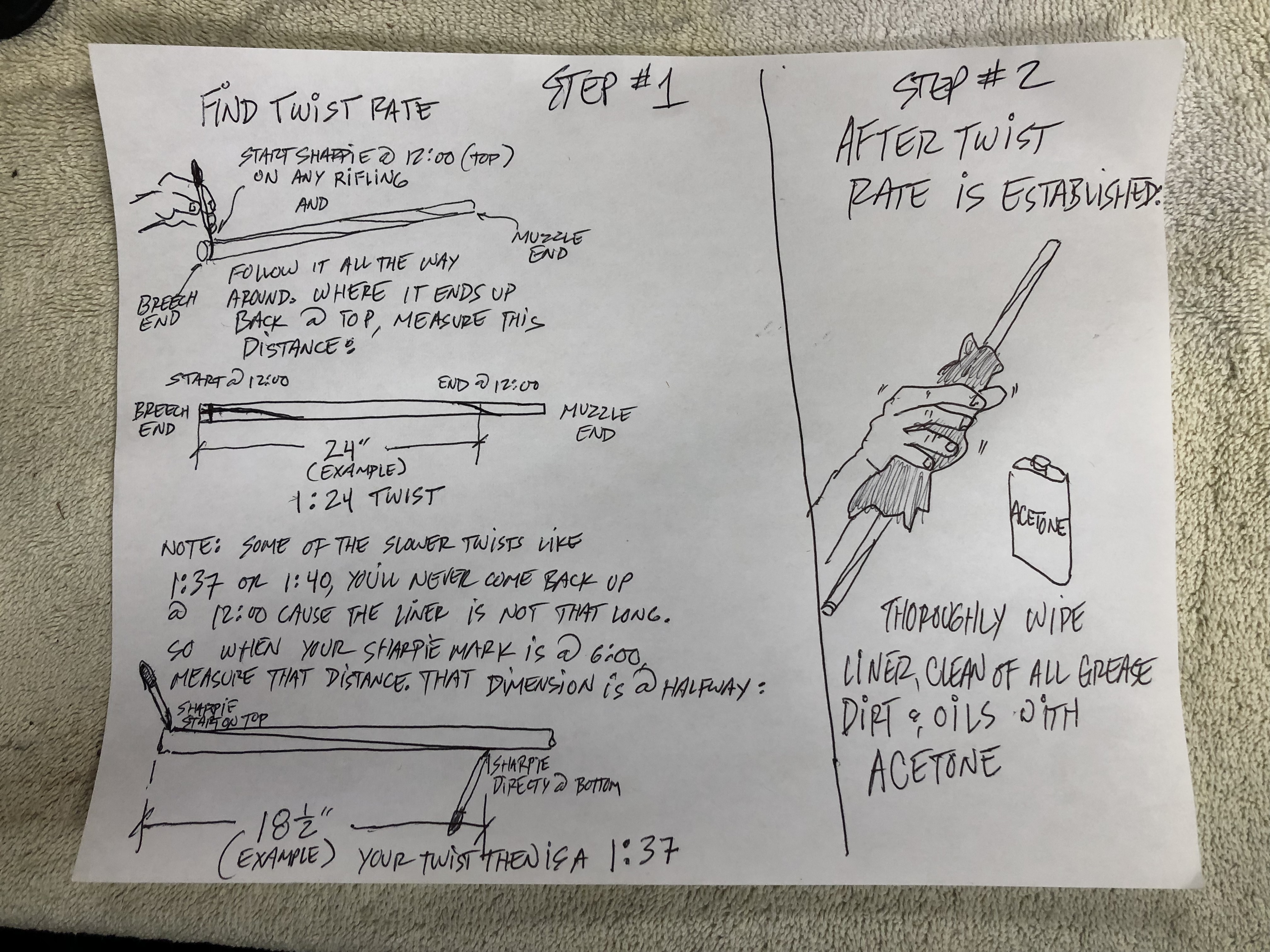

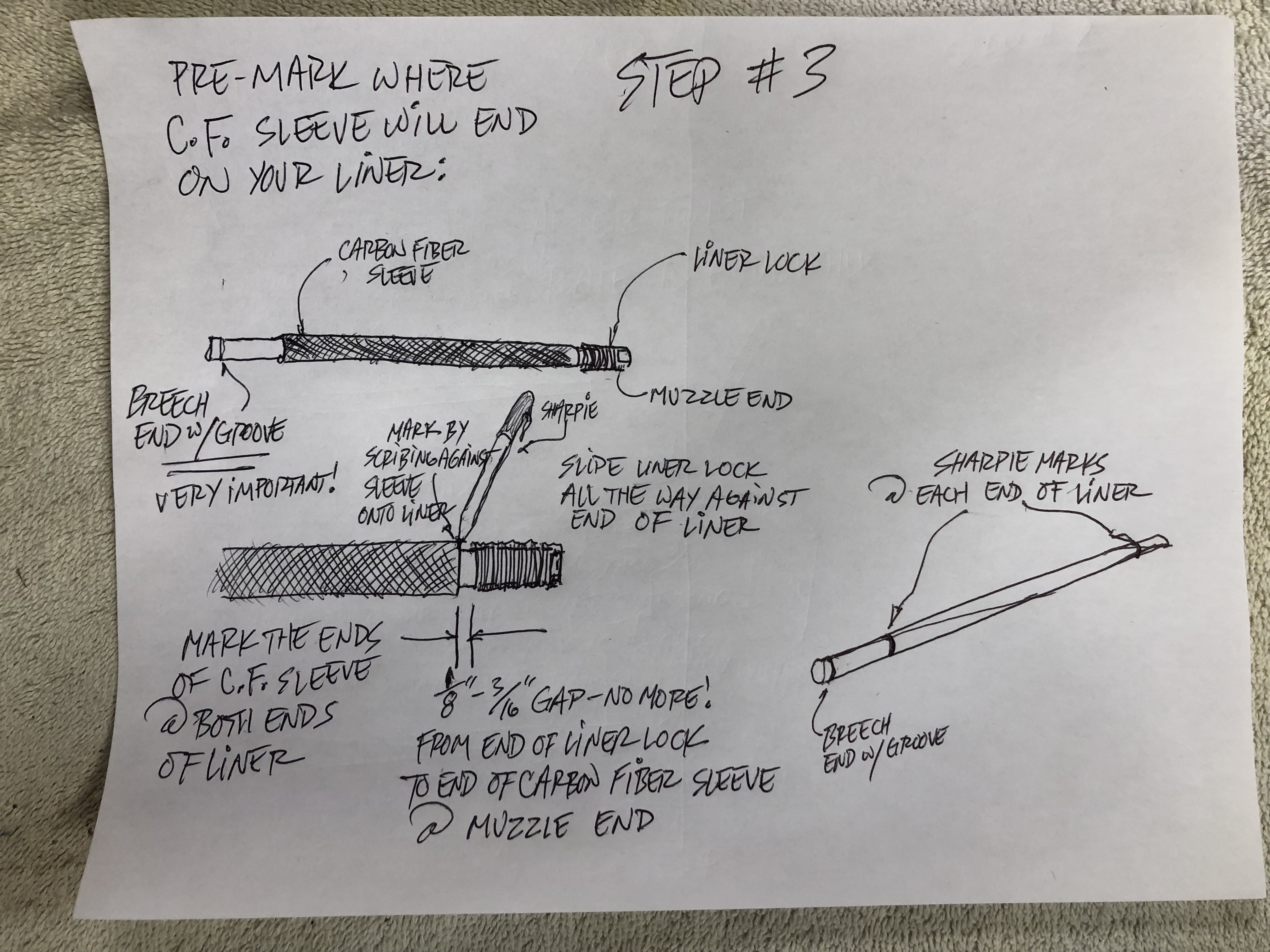

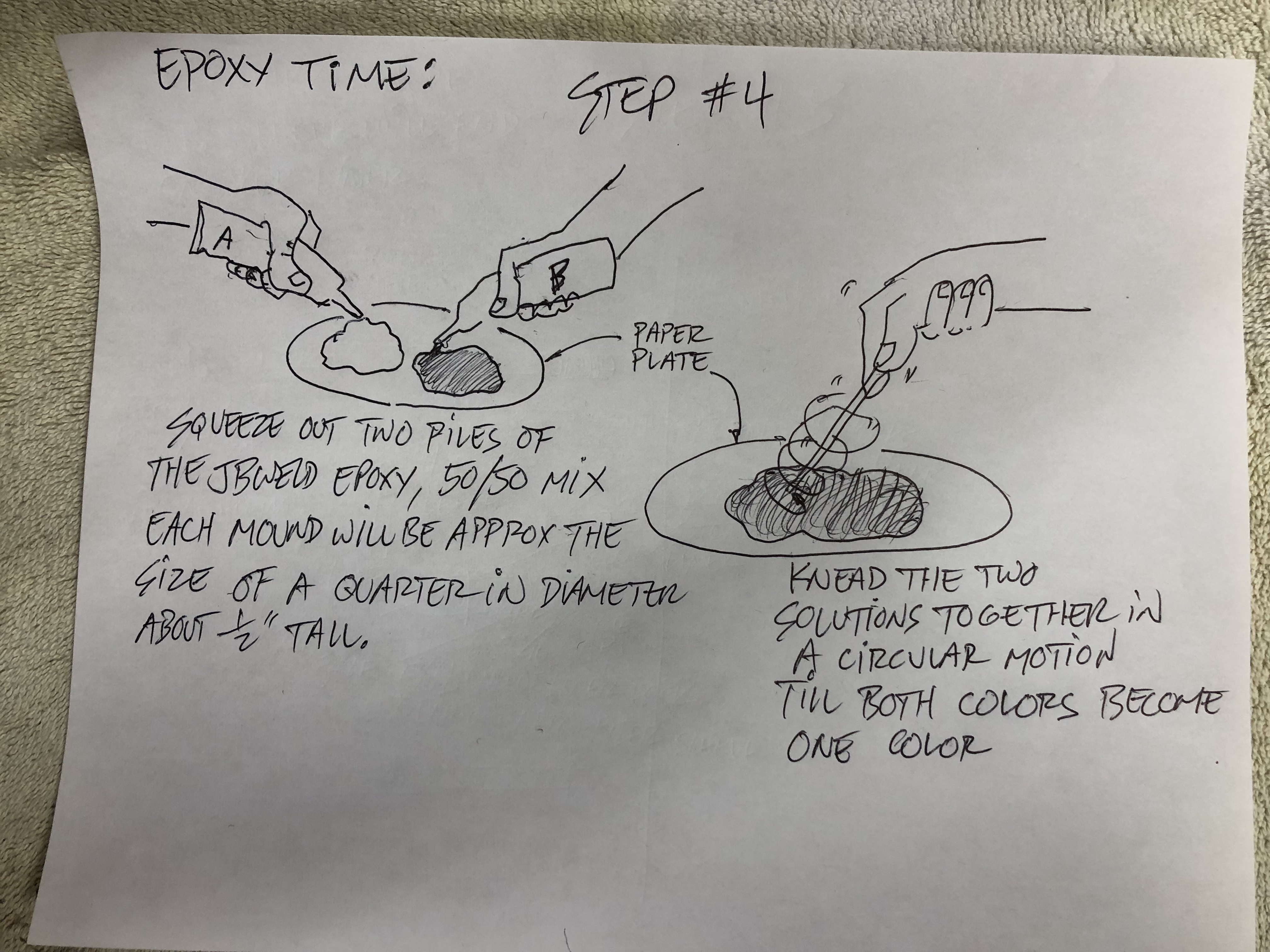

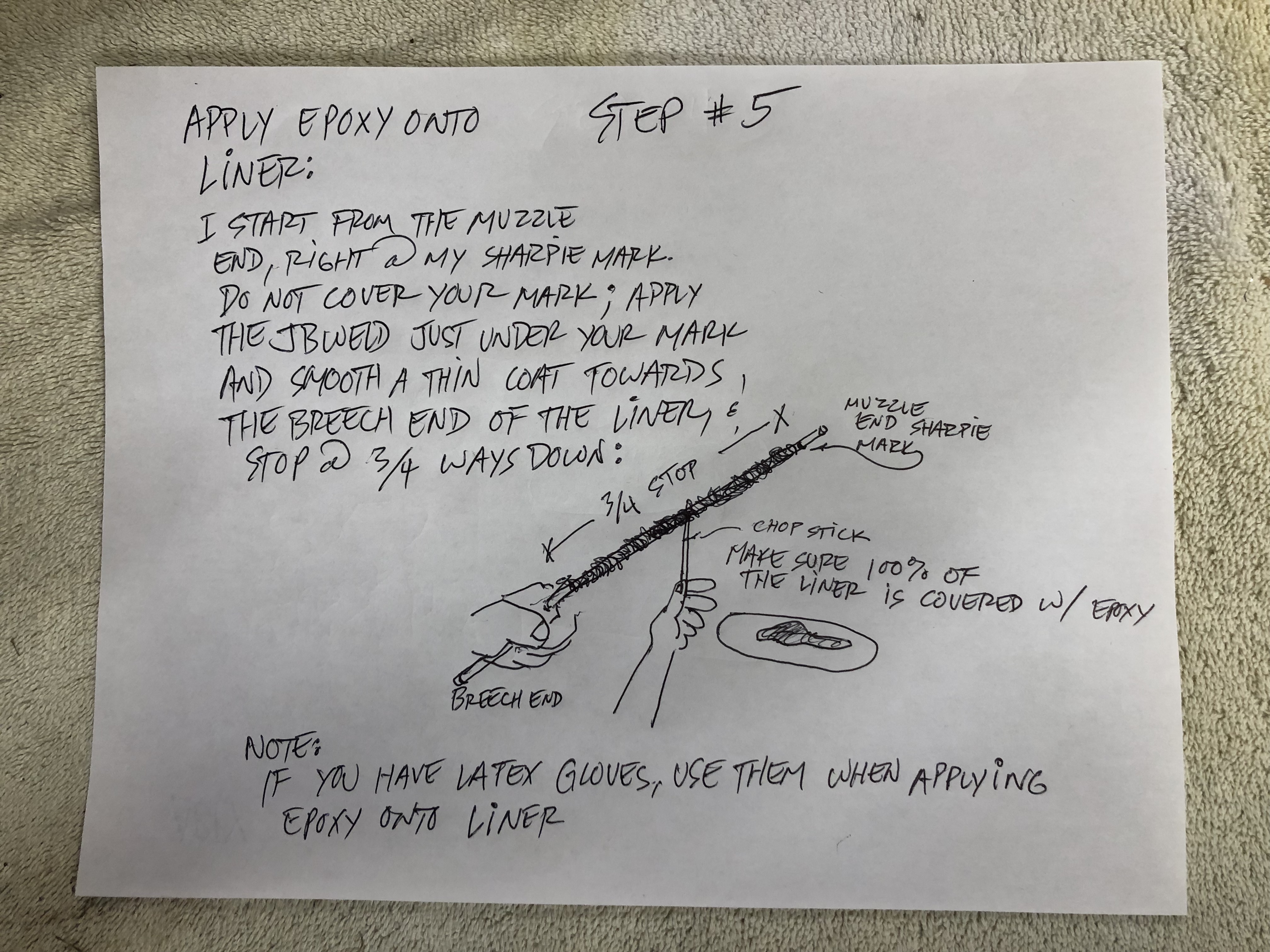

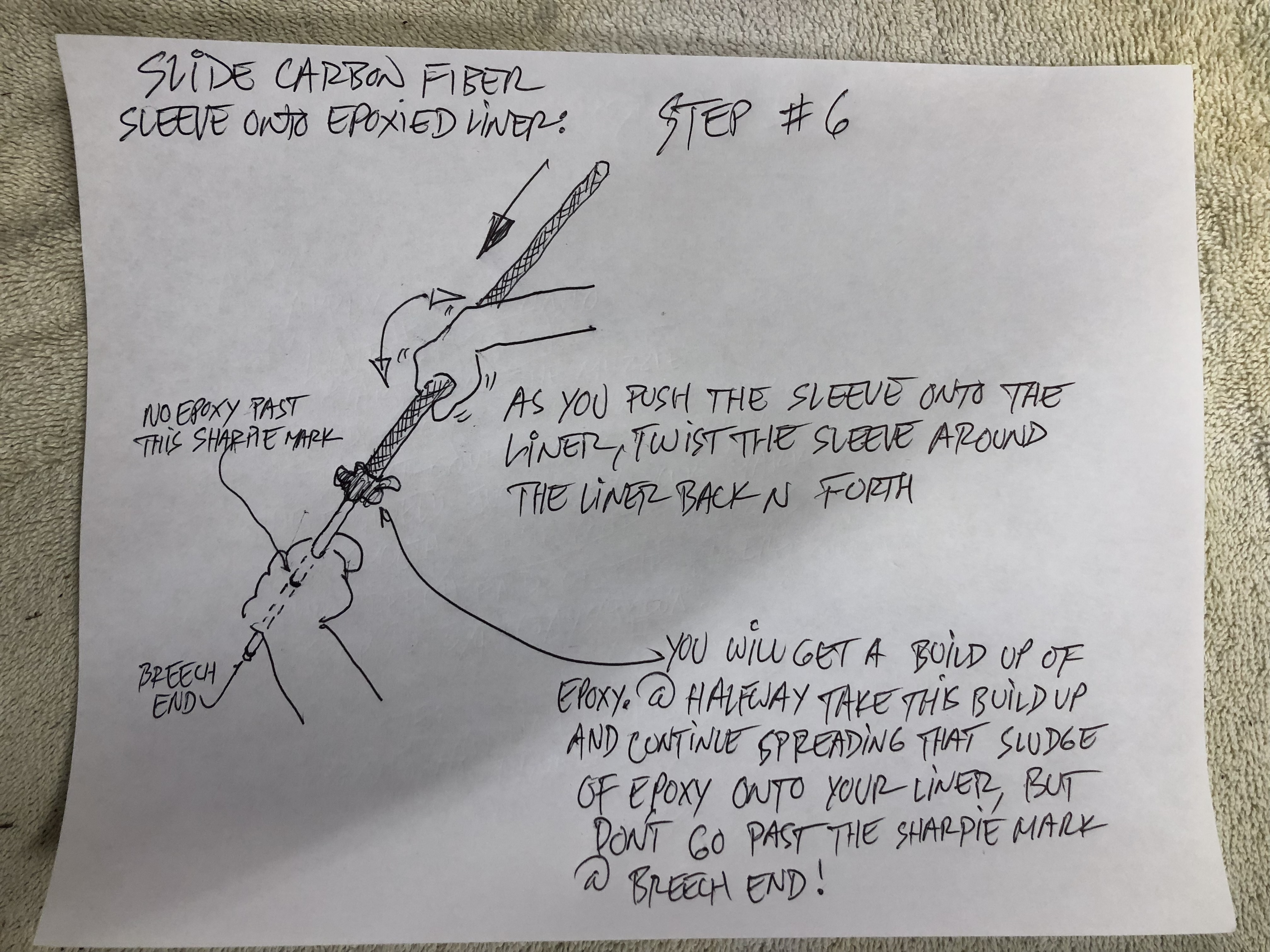

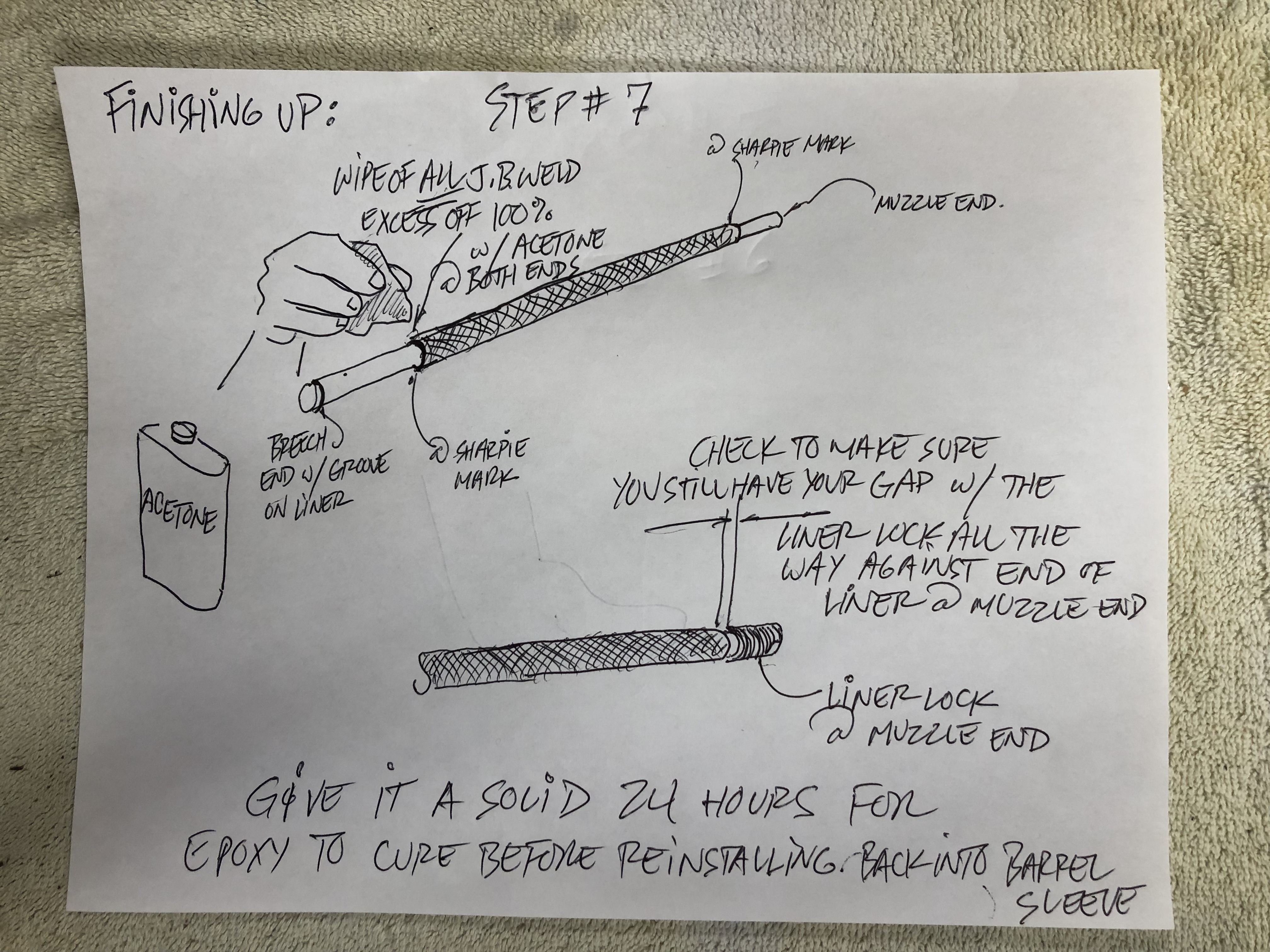

JBWeld standard set has always been my go to. I drew up a tutorial that I sent a member, and if no one minds, I’ll share it for those that have never epoxied a liner sleeve on before-

Upvote 0

I use JB also and the only thing I do that I didn’t see in Bigragu’s instructions is I clean the inside of the CF tube just like a barrel. Except I use acetone on the patches. Then pull a dry one through. The inside of the CF tube will have residue in it from when it was cut.

Upvote 0

Good catch- I also do that, I shove a piece of dry shop towel in one end, drizzle acetone onto the towel insert till I see it soaked, the ram it thru the sleeve with a rod/dowel.

Thanks for adding that, VETMX

Thanks for adding that, VETMX

Upvote 0

Again I find myself to be the odd-man-out

I'm not a fan of permanent mods where they can't be undone if the need should arise.

I have fit the tube over the liner and centered it so that it does not contact the adapter or liner lock then clean surfaces with brake cleaner.

I apply a tiny amount of 100% silicone caulk to one end of the tube where it contacts the liner and let it cure

Next day, I tip up the assembly in padded jaws and fill the void with silicone oil, clean the end of the tube and barrel and seal with the silicone caulk.

You do you, I'll do me

I'm not a fan of permanent mods where they can't be undone if the need should arise.

I have fit the tube over the liner and centered it so that it does not contact the adapter or liner lock then clean surfaces with brake cleaner.

I apply a tiny amount of 100% silicone caulk to one end of the tube where it contacts the liner and let it cure

Next day, I tip up the assembly in padded jaws and fill the void with silicone oil, clean the end of the tube and barrel and seal with the silicone caulk.

You do you, I'll do me

Upvote 0

NO! JMHO ==

As tight as mine was a literal had to be lubed and press fit haha I saw and see no need for it at all . So I guess I am the odd ball all of mine except 3 outta over 12 have been more than secure enough. On the 3 that were slip over I just used 1 round of Teflon tape and it had to be cleaned after installed. I feel the epoxy is overkill unless you are a competition shooter then it all gloves are off and I would try anything once haha.

As tight as mine was a literal had to be lubed and press fit haha I saw and see no need for it at all . So I guess I am the odd ball all of mine except 3 outta over 12 have been more than secure enough. On the 3 that were slip over I just used 1 round of Teflon tape and it had to be cleaned after installed. I feel the epoxy is overkill unless you are a competition shooter then it all gloves are off and I would try anything once haha.

Upvote 0