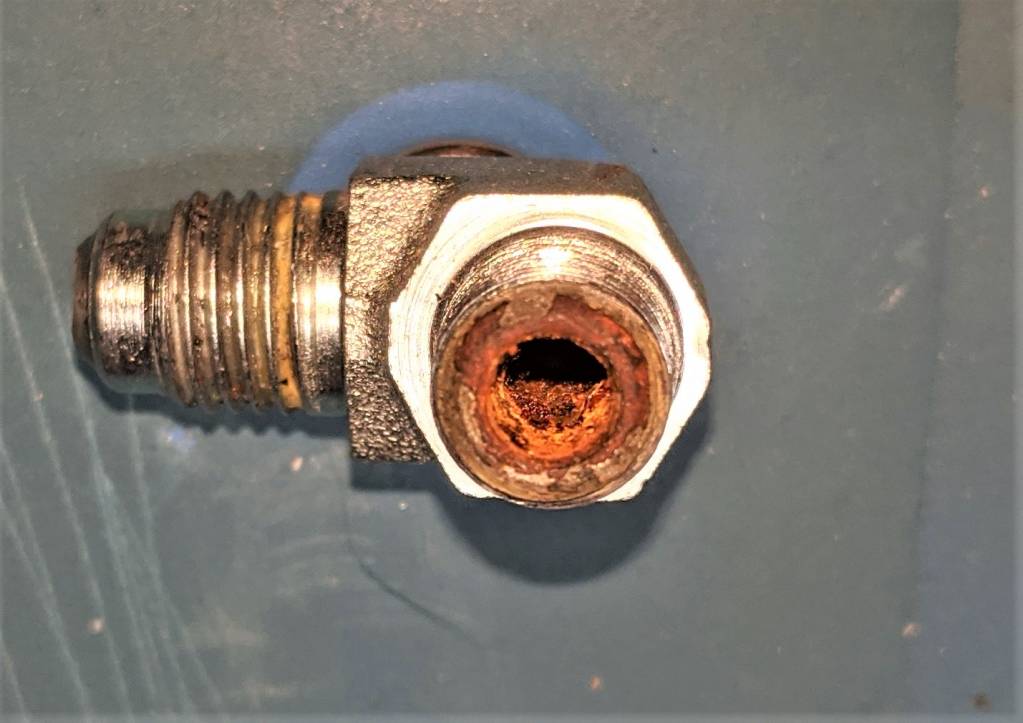

I just pulled this off a Daystate LC-110 purchased from AoA in Oct 2018. It's the 90 deg fitting that connected the condensation tower to the fill hose. Is this rust? Oil residue? Something else?

The output of the fitting looked relatively clean.

-Clayton

The output of the fitting looked relatively clean.

-Clayton