Well maybe not 100% moisture free, but if you use this method for filling and use a high quality moisture filter it will be as good as it gets for a YH.

First, start off with the right tank valve (scuba or scba) for our purposes. We don't need a valve with a stem that prevents contaminants from exiting the valve when tank is upside down. These valves are made with a stem hanging down inside tank to lessen the chance of the user breathing contaminant rolling around in the tank when in an inverted position as might happen during a emergency response team, or scuba diving.

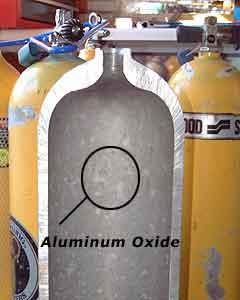

These pics are just to show valve stem construction, not to recommend any particular brand/type.

Here is a pic of the wrong valve for our purposes, imo.

Here is the right valve, notice no stem hanging down in tank.

There is a good reason for this choice of valve, I'll explain...

With this type valve its easy to invert your tank so valve(with no hose) is exactly at the 6 oclock position, then barely crack valve for a second, a couple/few times, this will purge all/majority of water out of tank. This must be done after tank has cooled off completely 100% cool so all water vapor created by the heat of compression by the YH will now be cooled/condensed into water droplets that can easily be purged/filtered out. Unlike water vapor thats difficult/impossible to filter/remove as a vapor. Thats why expensive HPA compressors use condenser coils to cool discharge air for ease of water removal. Its a good idea to facilitate water purge, store tank in an inverted position(valve at 6 oclock) while cooling and or filling. Always fill guns from an upright or horizontal tank.

After tank is purged of water now you can connect up as many filters/water separators/desiccants as you want, to successfully remove any remaining water/contaminants in you fill station hose to gun tank. Now cooled/condensed water droplets are easy for most any good filter to remove.

As for filling your tank from YH, I recommend the minimum(or none) filters/restrictions in YH discharge line to tank. As we are now filtering at the tank to gun fill station where we can more successfully/easily remove now cooled condensed contaminants. Doesn't really matter whats in the tank if we filter/purge it before it passes to gun. Also any restrictions in tank to gun fill station present no restriction concerns like on a compressor discharge line.

If you already have a valve like most do, its easy to mod it for easy tank purging. Measure your tank neck thread depth. Compare it to your valve length and cut valve stem off as needed. Don't worry, any valve threads past the neck do nothing for strength of valve to tank connection... If you're handy its easy to make a small recessed concave area at bottom of valve threads to facilitate funneling all water out the valve when purging...This is what the tank insides look like, a nice funnel to the tank neck threads. If we can match up flush/concave to this neck with our valves most all condensed water droplets will be easily purged out.

One warning for those not familiar with HP tank purging, when 'cracking' open the valve in an inverted position don't try to open it a half turn or anything like that. Open valve slowly(and shut it fast) just enough to get a very short blast to purge out contaminants/water. You wont lose much pressure and will now have a dry/drier tank.

In essence what this is doing, is using the tank to cool condense water vapor created by YH into more easily removed water droplets... The more expensive HPA compressors have discharge cooling coils to accomplish this, YH don't. So we can use the tank as our condenser.

jmo

First, start off with the right tank valve (scuba or scba) for our purposes. We don't need a valve with a stem that prevents contaminants from exiting the valve when tank is upside down. These valves are made with a stem hanging down inside tank to lessen the chance of the user breathing contaminant rolling around in the tank when in an inverted position as might happen during a emergency response team, or scuba diving.

These pics are just to show valve stem construction, not to recommend any particular brand/type.

Here is a pic of the wrong valve for our purposes, imo.

Here is the right valve, notice no stem hanging down in tank.

There is a good reason for this choice of valve, I'll explain...

With this type valve its easy to invert your tank so valve(with no hose) is exactly at the 6 oclock position, then barely crack valve for a second, a couple/few times, this will purge all/majority of water out of tank. This must be done after tank has cooled off completely 100% cool so all water vapor created by the heat of compression by the YH will now be cooled/condensed into water droplets that can easily be purged/filtered out. Unlike water vapor thats difficult/impossible to filter/remove as a vapor. Thats why expensive HPA compressors use condenser coils to cool discharge air for ease of water removal. Its a good idea to facilitate water purge, store tank in an inverted position(valve at 6 oclock) while cooling and or filling. Always fill guns from an upright or horizontal tank.

After tank is purged of water now you can connect up as many filters/water separators/desiccants as you want, to successfully remove any remaining water/contaminants in you fill station hose to gun tank. Now cooled/condensed water droplets are easy for most any good filter to remove.

As for filling your tank from YH, I recommend the minimum(or none) filters/restrictions in YH discharge line to tank. As we are now filtering at the tank to gun fill station where we can more successfully/easily remove now cooled condensed contaminants. Doesn't really matter whats in the tank if we filter/purge it before it passes to gun. Also any restrictions in tank to gun fill station present no restriction concerns like on a compressor discharge line.

If you already have a valve like most do, its easy to mod it for easy tank purging. Measure your tank neck thread depth. Compare it to your valve length and cut valve stem off as needed. Don't worry, any valve threads past the neck do nothing for strength of valve to tank connection... If you're handy its easy to make a small recessed concave area at bottom of valve threads to facilitate funneling all water out the valve when purging...This is what the tank insides look like, a nice funnel to the tank neck threads. If we can match up flush/concave to this neck with our valves most all condensed water droplets will be easily purged out.

One warning for those not familiar with HP tank purging, when 'cracking' open the valve in an inverted position don't try to open it a half turn or anything like that. Open valve slowly(and shut it fast) just enough to get a very short blast to purge out contaminants/water. You wont lose much pressure and will now have a dry/drier tank.

In essence what this is doing, is using the tank to cool condense water vapor created by YH into more easily removed water droplets... The more expensive HPA compressors have discharge cooling coils to accomplish this, YH don't. So we can use the tank as our condenser.

jmo