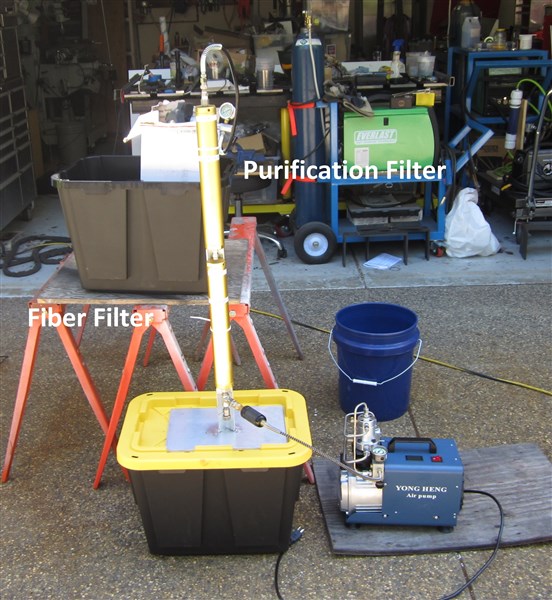

Pictured below is the filter I setup for my SCBA bottle filling using the Yong Heng compressor.

CONSTRUCTION

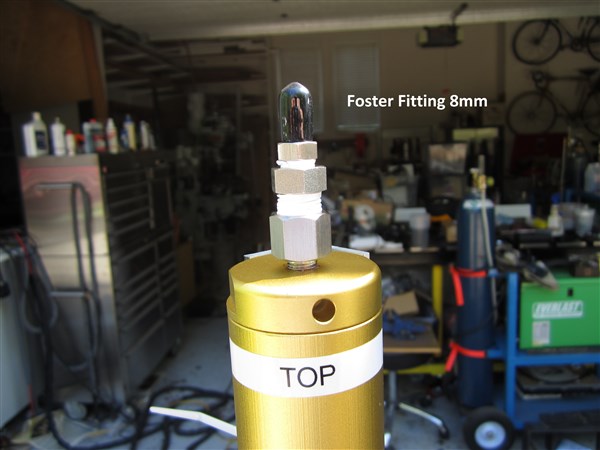

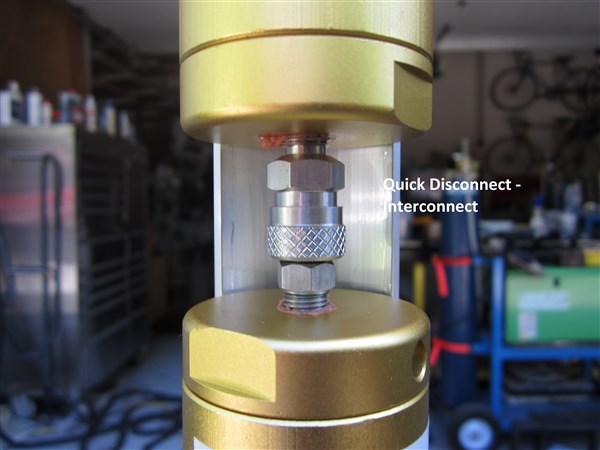

My filter setup consists of two Tux filters in a vertical inline configuration. The bottom section is a standard fiber filter and the top one contains the purification media. Both filters are interconnected with quick connect fittings for ease of media replacement.

I purchased many of the fittings from Titon Fittings, one type from Amazon, petcock from FilterTech and the others from various AliExpress paint ball/PCP airgun dealers. Titon ran out of the lower "T" fitting and a few days later shipped me the same item made by World Wide Fittings. It was

not of the same fit and finish as their in-house stuff. The threaded male side going to the check valve had almost no taper. It would only grab a few threads before becoming hand tight. I ended up using a die to reform the threads until it could be inserted at least 1/4" before becoming hand tight. The threads on the two other sides of the "T" were fine.

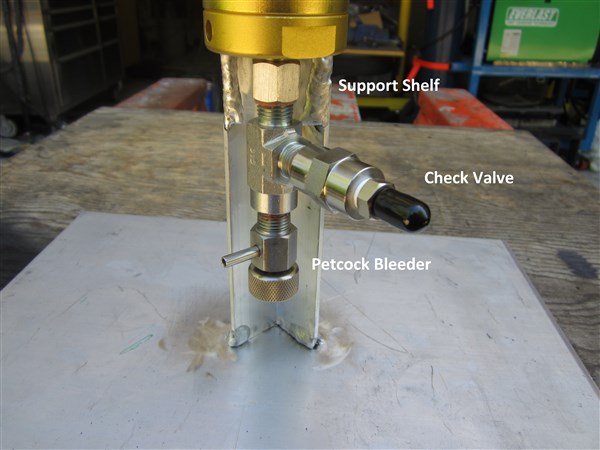

Most of the fittings were put together with Vibra-TITE 440 anaerobic thread sealant and Vibra-TITE 612 adhesive primer. This sealant is made for high pressure and was very interesting to work with. Fitting made of stainless steel and a few other metals are nonreactive causing a very slow cure process. I found this out the hard way. Excess adhesive would ooze from the joints and never dry. Although material that came out of the joint did not cure, sealant on the threads not exposed to air did cure eventually. The primer causes the joint to cure faster and excess material that comes out of the joint will cure. The bottom check valve and the upper two joints were sealed with Teflon tape for easy removal.

The upper section of the filter has two teflon tape sealed joints to allow for a priority valve to be installed later if I desire. I bought the valve but decided not to use it because it has a built-in check valve that would prevent pressurizing the filter. The valve isn't necessary if topping off the tank

is what I will be doing. I had my Ebay SCBA tank hydro'd and filled to the 3500 PSI maximum for my local dive shop. The lower check valve allows me to pressurize the filter prior to starting the pump. This minimizes moisture buildup in the filter media.

My filter stand is pretty simple. It consists of a piece of 1 1/4" angle aluminum and is welded to a 1/4" thick piece of scrap plate aluminum. A small angle cut piece of angle aluminum was welded in place to act as a shelf for the filter keeping it roughly 6" off the base. My filter attachment method is just as simple.....two tie wraps.

My Yong Heng is setup just like most folks do in the forum. The filters are above the compressor and cooling water at the same level. Royal Purple Synfilm Recip is used to lubricate the compressor.

OPERATION

I decided to test the filter for leaks before setting it up for filling a bottle. This was done by pressurizing it using my SCBA bottle. The check valve on the outlet prevented air from leaking out of the filter. It held air for about 20 minutes with no obvious leaks.

The next day I setup for pressurizing my SCBA bottle to 4200 PSI. It worked very well except for a few gotchas. The dive shop pressurized my SCBA bottle to 3500 PSI. I noted my bottle was really hot when I carried it back to the car. The next day the pressure was down to about 3000 PSI and stayed there. I brought the tank up to 4200 PSI with my setup and it dove to 4000 PSI overnight. This all makes sense since hot air in a fixed volume will drop in pressure as it cools.

My 5 gallon water bucket was filled with ice water and the temperature stayed below 50 C. As the pressure approached 4200 PSI, I noticed periodic fine spit misting coming from what appeared to be the upper head of the compressor. It only happened for a split second and would reoccur every few minutes or so. I decided to focus on filling my tank correctly and leave the hunt for the leak to later. Connections and head bolts all seem to be tight.

CONSTRUCTION

My filter setup consists of two Tux filters in a vertical inline configuration. The bottom section is a standard fiber filter and the top one contains the purification media. Both filters are interconnected with quick connect fittings for ease of media replacement.

I purchased many of the fittings from Titon Fittings, one type from Amazon, petcock from FilterTech and the others from various AliExpress paint ball/PCP airgun dealers. Titon ran out of the lower "T" fitting and a few days later shipped me the same item made by World Wide Fittings. It was

not of the same fit and finish as their in-house stuff. The threaded male side going to the check valve had almost no taper. It would only grab a few threads before becoming hand tight. I ended up using a die to reform the threads until it could be inserted at least 1/4" before becoming hand tight. The threads on the two other sides of the "T" were fine.

Most of the fittings were put together with Vibra-TITE 440 anaerobic thread sealant and Vibra-TITE 612 adhesive primer. This sealant is made for high pressure and was very interesting to work with. Fitting made of stainless steel and a few other metals are nonreactive causing a very slow cure process. I found this out the hard way. Excess adhesive would ooze from the joints and never dry. Although material that came out of the joint did not cure, sealant on the threads not exposed to air did cure eventually. The primer causes the joint to cure faster and excess material that comes out of the joint will cure. The bottom check valve and the upper two joints were sealed with Teflon tape for easy removal.

The upper section of the filter has two teflon tape sealed joints to allow for a priority valve to be installed later if I desire. I bought the valve but decided not to use it because it has a built-in check valve that would prevent pressurizing the filter. The valve isn't necessary if topping off the tank

is what I will be doing. I had my Ebay SCBA tank hydro'd and filled to the 3500 PSI maximum for my local dive shop. The lower check valve allows me to pressurize the filter prior to starting the pump. This minimizes moisture buildup in the filter media.

My filter stand is pretty simple. It consists of a piece of 1 1/4" angle aluminum and is welded to a 1/4" thick piece of scrap plate aluminum. A small angle cut piece of angle aluminum was welded in place to act as a shelf for the filter keeping it roughly 6" off the base. My filter attachment method is just as simple.....two tie wraps.

My Yong Heng is setup just like most folks do in the forum. The filters are above the compressor and cooling water at the same level. Royal Purple Synfilm Recip is used to lubricate the compressor.

OPERATION

I decided to test the filter for leaks before setting it up for filling a bottle. This was done by pressurizing it using my SCBA bottle. The check valve on the outlet prevented air from leaking out of the filter. It held air for about 20 minutes with no obvious leaks.

The next day I setup for pressurizing my SCBA bottle to 4200 PSI. It worked very well except for a few gotchas. The dive shop pressurized my SCBA bottle to 3500 PSI. I noted my bottle was really hot when I carried it back to the car. The next day the pressure was down to about 3000 PSI and stayed there. I brought the tank up to 4200 PSI with my setup and it dove to 4000 PSI overnight. This all makes sense since hot air in a fixed volume will drop in pressure as it cools.

My 5 gallon water bucket was filled with ice water and the temperature stayed below 50 C. As the pressure approached 4200 PSI, I noticed periodic fine spit misting coming from what appeared to be the upper head of the compressor. It only happened for a split second and would reoccur every few minutes or so. I decided to focus on filling my tank correctly and leave the hunt for the leak to later. Connections and head bolts all seem to be tight.