Wow, three strikes on this product. After the first two strikes, I was just going to call AOA and let them know they had tolerance issues with this product, but with strike three (a safety issue) I need to make a post.

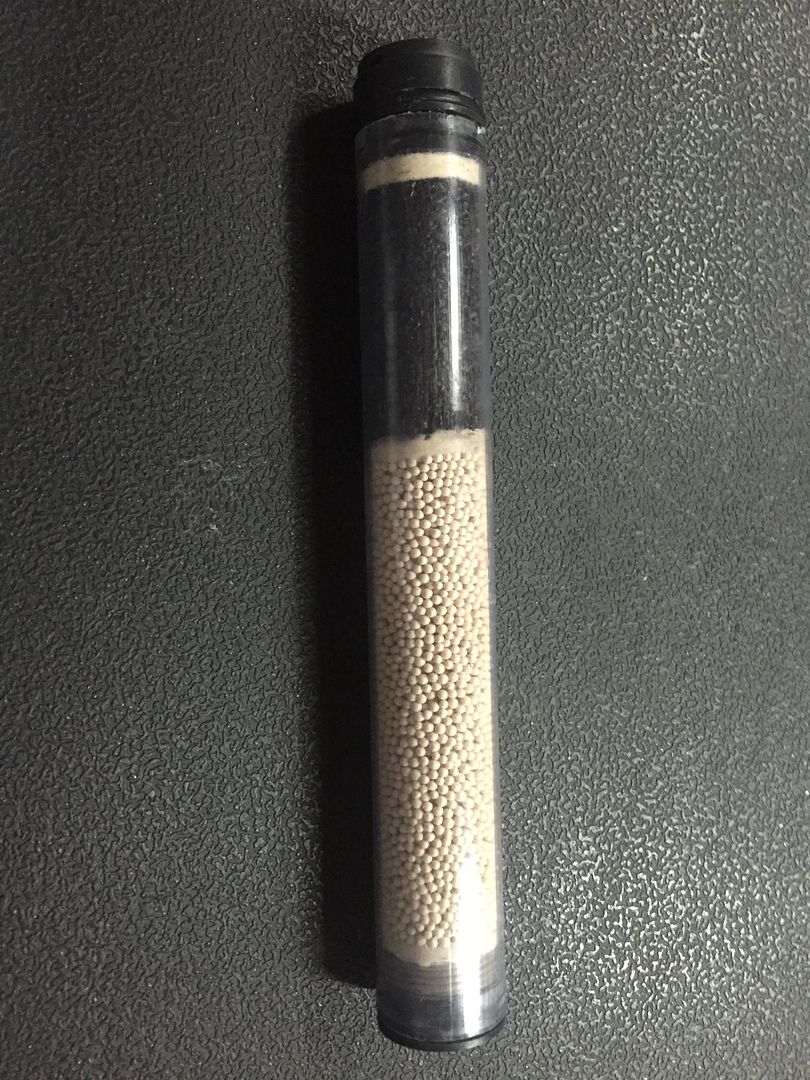

First Strike: Tolerance issue. The depth from the center of the bearings to the face is normally around .1 On the Diablo it is .18 or .19 on the one they sent me. This results in the face of the female adapter contacting the face of the male piece before the bearing engage and hence the hose will not stay connected. You could fix this by grinding the face of the female adapter back down to normal or grinding down all your male adapters. Hmmmmm

Second Strike. Tolerance issue. The outside diameter of a normal female foster fitting is around .650 to .655. The diameter on the Diablo filter is around .750. In and of itself that isn't a big issue. Unless.... you are trying to connect it to something that has a area around the male foster cut to allow for a normal .650 fitting. For example my ShoeBox Fredom 8 only has a .711 cut out. That means there is no way to connect this to the ShoeBox without (a) enlarging the opening on the ShoeBox or (b) running the ShoeBox without it's cover on (not a great idea where curious kids or pets are around).

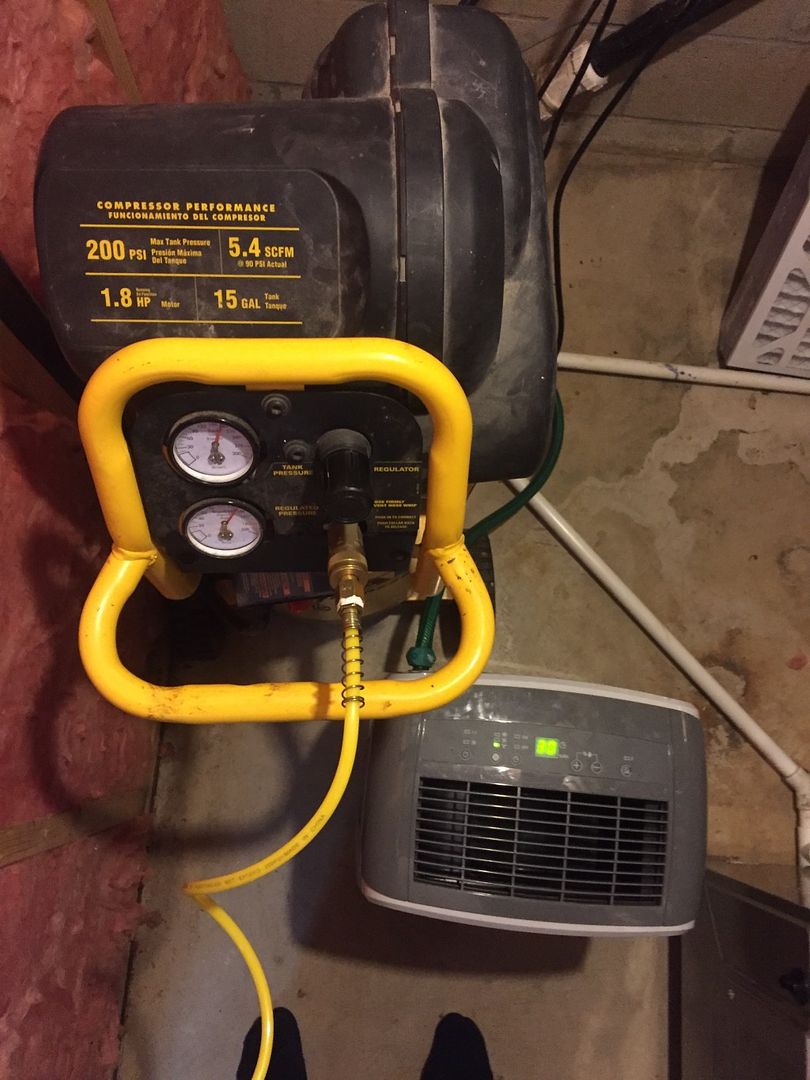

Strike Three: BANG!!!! And the reason for the post. I'm sorry vendors/sponsors but when your product which is designed to operate at 4500 psi explodes in proximity to me, you score a negative post.

The Airguns of Arizona site says this is "Tested to 6000 psi for Safety" Yes, they used a capitol S in Safety. I'm calling BS on this unit being tested to 6000 psi. I started with an empty Tigershark tank (drained to 0 psi so I could fill it with dry air) and connected the dryer to the tank and ShoeBox (after grinding on my ShoeBox to get it to connect) and started the compressor. At about 500psi the Diablo's hose exploded, sending casing flying and bending the metal around the explosion site. Sounded like a .22 CCI stinger going off by my ear, which is still ringing as I write this.

Burst hose at 500 psi - on it's first fill but "Tested to 6000 psi" - I think not.

Who knows what would have happened if instead of connecting it to an empty tank and walking away a bit (like I did) I had connected it to a tank still at 2500 or 3000 psi and opened the tank!! My hand would have been on the tank valve less than 4 inches from where it exploded.

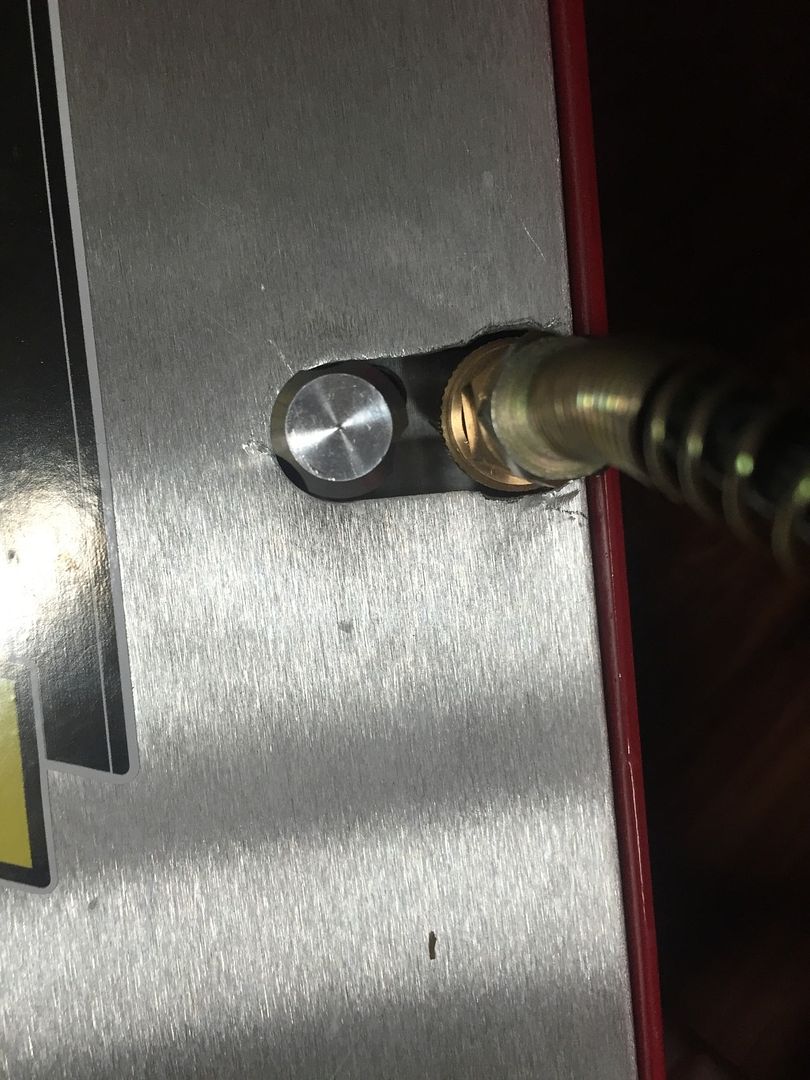

Incorrectly sized fitting. Look at the gap between the face of the outer fitting and the face of the inner fitting. That much material has to be removed from either the dryer's fitting or all your male foster fittings where you plan to use this if it is going to work. This would not fit my tank, compressor, or regulator, or guns male fittings. It did fit the nice male plug that came with it though, From a diameter perspective, forget about this connecting to the male on your FX impact (if you want to dry the air between your tank/compressor and FX Impact.

At least they named it right:· • Diablo• From Wikipedia, the free encyclopedia• Diablo [diˈaβlo] is a Spanish word, meaning "Devil".

First Strike: Tolerance issue. The depth from the center of the bearings to the face is normally around .1 On the Diablo it is .18 or .19 on the one they sent me. This results in the face of the female adapter contacting the face of the male piece before the bearing engage and hence the hose will not stay connected. You could fix this by grinding the face of the female adapter back down to normal or grinding down all your male adapters. Hmmmmm

Second Strike. Tolerance issue. The outside diameter of a normal female foster fitting is around .650 to .655. The diameter on the Diablo filter is around .750. In and of itself that isn't a big issue. Unless.... you are trying to connect it to something that has a area around the male foster cut to allow for a normal .650 fitting. For example my ShoeBox Fredom 8 only has a .711 cut out. That means there is no way to connect this to the ShoeBox without (a) enlarging the opening on the ShoeBox or (b) running the ShoeBox without it's cover on (not a great idea where curious kids or pets are around).

Strike Three: BANG!!!! And the reason for the post. I'm sorry vendors/sponsors but when your product which is designed to operate at 4500 psi explodes in proximity to me, you score a negative post.

The Airguns of Arizona site says this is "Tested to 6000 psi for Safety" Yes, they used a capitol S in Safety. I'm calling BS on this unit being tested to 6000 psi. I started with an empty Tigershark tank (drained to 0 psi so I could fill it with dry air) and connected the dryer to the tank and ShoeBox (after grinding on my ShoeBox to get it to connect) and started the compressor. At about 500psi the Diablo's hose exploded, sending casing flying and bending the metal around the explosion site. Sounded like a .22 CCI stinger going off by my ear, which is still ringing as I write this.

Burst hose at 500 psi - on it's first fill but "Tested to 6000 psi" - I think not.

Who knows what would have happened if instead of connecting it to an empty tank and walking away a bit (like I did) I had connected it to a tank still at 2500 or 3000 psi and opened the tank!! My hand would have been on the tank valve less than 4 inches from where it exploded.

Incorrectly sized fitting. Look at the gap between the face of the outer fitting and the face of the inner fitting. That much material has to be removed from either the dryer's fitting or all your male foster fittings where you plan to use this if it is going to work. This would not fit my tank, compressor, or regulator, or guns male fittings. It did fit the nice male plug that came with it though, From a diameter perspective, forget about this connecting to the male on your FX impact (if you want to dry the air between your tank/compressor and FX Impact.

At least they named it right:· • Diablo• From Wikipedia, the free encyclopedia• Diablo [diˈaβlo] is a Spanish word, meaning "Devil".