Over my serious air gun career, I have never found a spinner target that really worked very well over a long period of time. The ones you purchase are either (A) too light and they self destruct, (B) too heavy and will not spin, or (C) are of the polymer "self healing" variety that over time get distorted and then don't want to spin.

Reading what others have created, I have borrowed some really good ideas, and have created a target that really works well at all yards, for all of my rifles from the AA TX200 <12 ft lb to the AA S510 .25 shooting 33.95 JSB Kings.

I have been shooting the original "prototype" for an entire summer with no signs of any kinds of issues. So for those who like to "do it yourself," here goes.

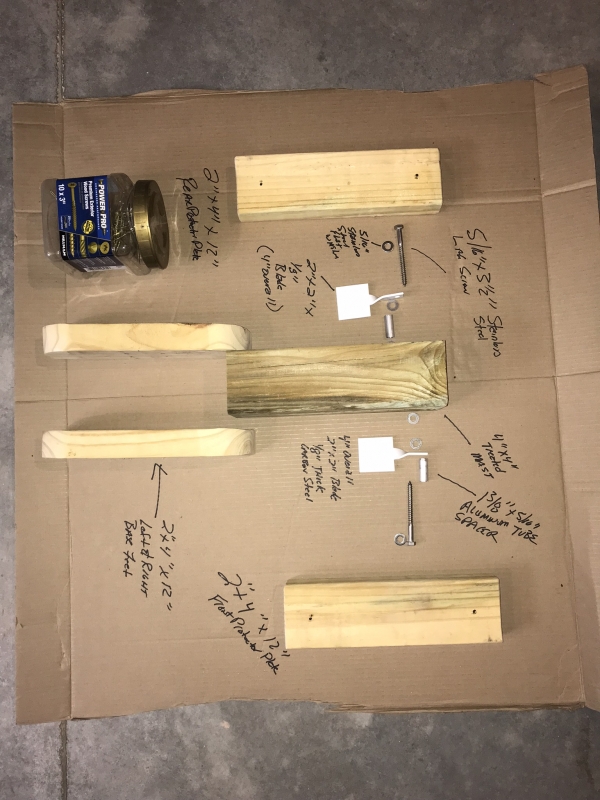

All items purchased are available from Lowe's. A photo of the build list is included below. The main column is a treated 4" x 4" post section. The blades are made of 2" x 1/8" mild steel stock, with the original prototype blades being cut outing using a 4" body grinder with cutting blade. I used a propane torch and a crescent wrench to bend the blades in a vise to give them the desired twist and cut out the 5/16" hole on my drill press. The bolts and washers are 5/16" stainless steel so rust and weather are not factors. The feet are made of treated 2" x 4." I used coated #10 x 3" deck screws for assembly. The spinner blade spacers are cut from a 5/16" aluminum pipe section and need to be 1 1/2" long to adequately clear the column post.

The 2" x 4" x 1' front and rear plates are to protect the 4" x 4" column post. Held with 2 #10 x 3" coated deck screws, should they get shot up too bad, they can easily be replaced. I will tell you that after an entire summer of shooting, mine are still in great shape.

After heating and bending the blades, soaked them overnight in a solution of water/dawn detergent to remove the oils, then after drying, painted them with Rustoleum primer, followed up by a finish coat of Rustoleum.

These targets really work slick and are heavy enough that they don't move around, even with the .25. The <12 ft lb .177 at 50 yards usually won't spin the blade all of the way around, but they will rock half way up the cycle. At 80 yards, all of my pcps will still spin the blades, and even at 20 yards, the blades will not distort, with even the .25 pcp.

These are fun to make. As the lumber comes in 8' sections and the steel bar stock in 3' sections, you might as well make at least 4 of these at a time.

Hopefully, this post will help a few of my AGN peers to enjoy their shooting even more!

If you decide to try these, they are fun to make.

Reading what others have created, I have borrowed some really good ideas, and have created a target that really works well at all yards, for all of my rifles from the AA TX200 <12 ft lb to the AA S510 .25 shooting 33.95 JSB Kings.

I have been shooting the original "prototype" for an entire summer with no signs of any kinds of issues. So for those who like to "do it yourself," here goes.

All items purchased are available from Lowe's. A photo of the build list is included below. The main column is a treated 4" x 4" post section. The blades are made of 2" x 1/8" mild steel stock, with the original prototype blades being cut outing using a 4" body grinder with cutting blade. I used a propane torch and a crescent wrench to bend the blades in a vise to give them the desired twist and cut out the 5/16" hole on my drill press. The bolts and washers are 5/16" stainless steel so rust and weather are not factors. The feet are made of treated 2" x 4." I used coated #10 x 3" deck screws for assembly. The spinner blade spacers are cut from a 5/16" aluminum pipe section and need to be 1 1/2" long to adequately clear the column post.

The 2" x 4" x 1' front and rear plates are to protect the 4" x 4" column post. Held with 2 #10 x 3" coated deck screws, should they get shot up too bad, they can easily be replaced. I will tell you that after an entire summer of shooting, mine are still in great shape.

After heating and bending the blades, soaked them overnight in a solution of water/dawn detergent to remove the oils, then after drying, painted them with Rustoleum primer, followed up by a finish coat of Rustoleum.

These targets really work slick and are heavy enough that they don't move around, even with the .25. The <12 ft lb .177 at 50 yards usually won't spin the blade all of the way around, but they will rock half way up the cycle. At 80 yards, all of my pcps will still spin the blades, and even at 20 yards, the blades will not distort, with even the .25 pcp.

These are fun to make. As the lumber comes in 8' sections and the steel bar stock in 3' sections, you might as well make at least 4 of these at a time.

Hopefully, this post will help a few of my AGN peers to enjoy their shooting even more!

If you decide to try these, they are fun to make.