Anyone know where to find a 1/2-20 male to 1/2-28 male adapter to allow using an ldc that has a 1/2-28 female thread on the Tx200 HC.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tx200 HC ldc

- Thread starter Jonah

- Start date

I haven't seen a stock adapter that goes from 1/2x20 to 1/2x28, but here you can get a custom adapter made:

https://donnyfl.com/collections/adapters/products/custom-adapter

https://donnyfl.com/collections/adapters/products/custom-adapter

Upvote 0

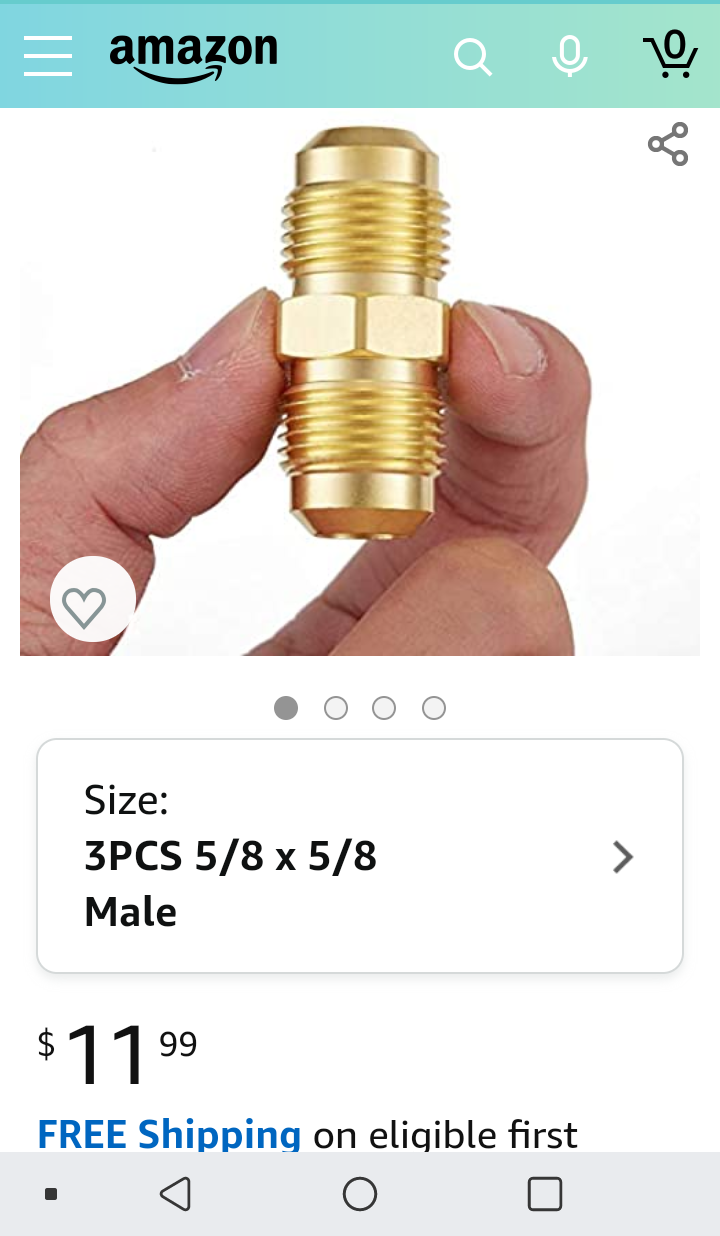

Had a similar question asked from a cheapie tightwad guy who didn't want to pay too much for a proper purposeful adapter and so suggested buying items like these cheapies locally then chase the threads with a tap and die or thread chaser since they're only soft brass. He said he didn't have such tools and screwed both right in and worked for him. He must have used 2 threaded nuts as makeshift tools to lock then screw into gun and muscle the LDC on to reshape the threads. Must have taken a while constantly going in and out rethreading to do it that way. Chasing-redoing the threads with tap and die on both ends with specific sizes is the right way to do it though. I suggested going 5/8 if the 1/2 didn't work but that requires proper tap and die.

Upvote 0

G

Guest

Guest

Leo, I sent you a text of a muzzle break I was looking for a FWB300. They should be able to help.

Mitch

Mitch

Upvote 0

If anyone doesn't have a proper tap and die to thread the brass adapters perfectly you can make your own by buying steel (not anything soft not brass) hex nuts that have the exact threading like your threaded barrel and LDC has then use a hacksaw-jigsaw blade and cut across the inner nut threads 4 cuts 12 o'clock 3oclock 6oclock and 9oclock positions all at a slight angle. Then screw it to the brass adapter deeper cut side screwing in and out a little at a time till it goes all the way. Same applies for a stripped female threaded hole. Hacksaw a proper thread matching steel hex bolt at 4 positions slightly angled towards the threads' tip.

Upvote 0

THIS may be helpful it's recessed FEMALE is a hair over 1/2" so added to a Brass 5/8" double male coupler or cheaper 5/8" brass nipple RE-threaded properly differently from both ends will work OR! use the 1/2" and JB WELD one end into the 13.5x1 female and thread chase tap and die the other end to 1/2 unfx20 to screw in the gun. Shorten all brass go between appropriately hacksaw and file if needed to prevent premature bottoming out the threads to keep everything short and neat flush with the end of the muzzle. At least you are threading your steel (I ASSUME?) 1/2x28 (TAX STAMP?) directly onto properly matched steel threads instead of redone soft brass for longevity and repeatability sake.

https://www.ebay.com/itm/All-Steel-Muzzle-Thread-Adapter-Convert-13-5x1-LH-to-1-2x28-w-Crush-Washer/114145625300?_trkparms=aid%3D555021%26algo%3DPL.SIMRVI%26ao%3D1%26asc%3D225080%26meid%3D96d9a5c293a747e8af34b3da77dd9642%26pid%3D100935%26rk%3D1%26rkt%3D6%26mehot%3Dpf%26sd%3D224148269309%26itm%3D114145625300%26pmt%3D1%26noa%3D0%26pg%3D2332490%26algv%3DSimplRVIAMLv5NativeWithPLRVIOnTopCombiner&_trksid=p2332490.c100935.m2460

https://www.ebay.com/itm/All-Steel-Muzzle-Thread-Adapter-Convert-13-5x1-LH-to-1-2x28-w-Crush-Washer/114145625300?_trkparms=aid%3D555021%26algo%3DPL.SIMRVI%26ao%3D1%26asc%3D225080%26meid%3D96d9a5c293a747e8af34b3da77dd9642%26pid%3D100935%26rk%3D1%26rkt%3D6%26mehot%3Dpf%26sd%3D224148269309%26itm%3D114145625300%26pmt%3D1%26noa%3D0%26pg%3D2332490%26algv%3DSimplRVIAMLv5NativeWithPLRVIOnTopCombiner&_trksid=p2332490.c100935.m2460

Upvote 0