Hi guys,

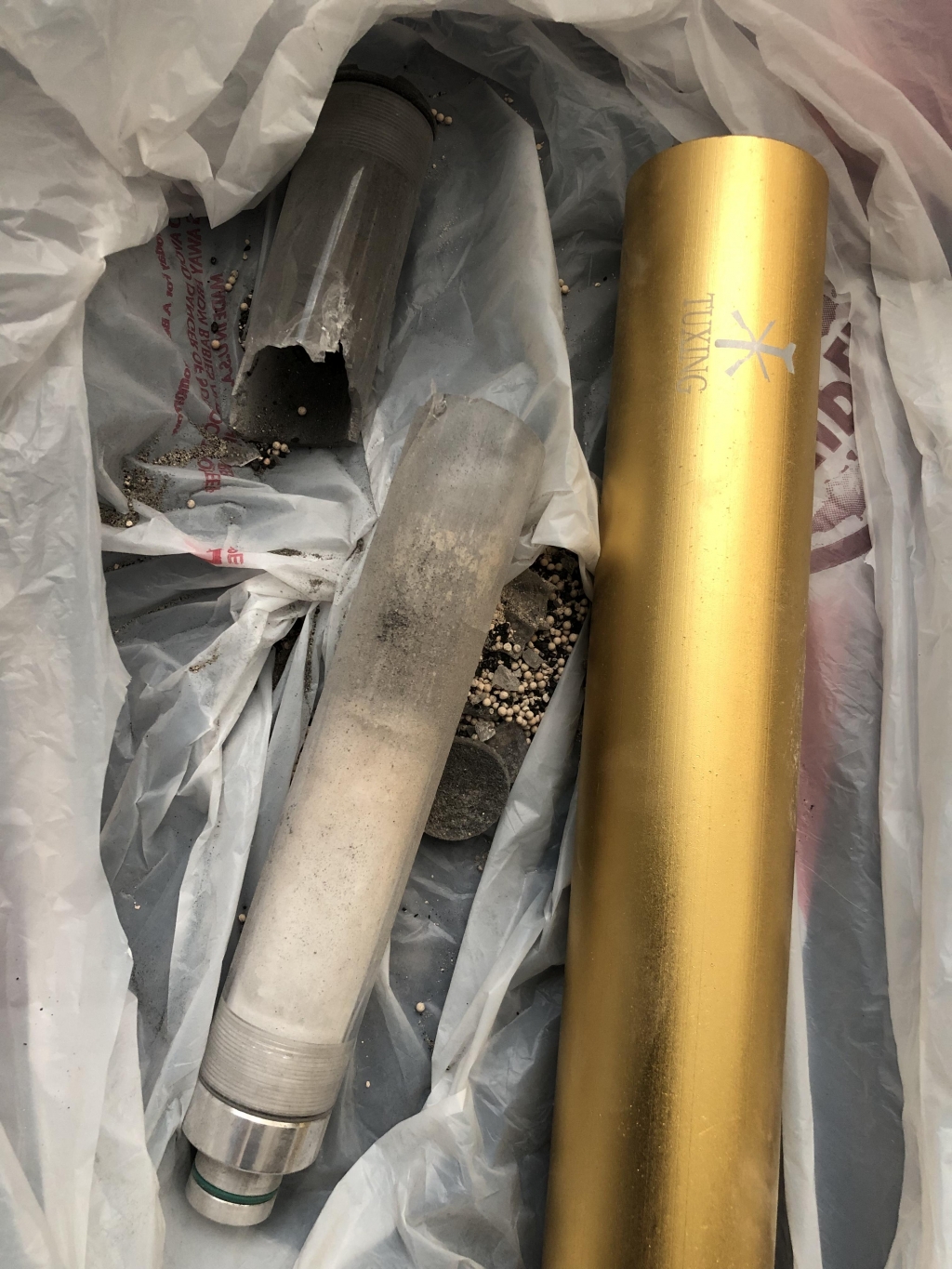

Well, this happened today:

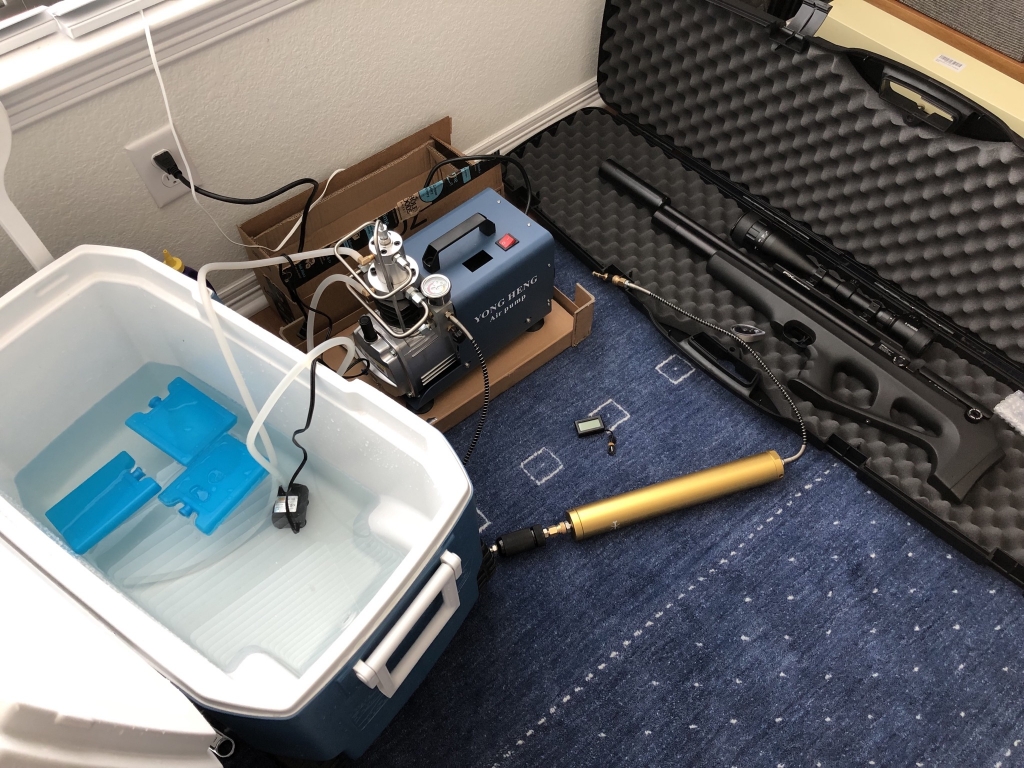

Below is my pump setup:

Everything you see in this picture are pretty much new. It was only the second time directly filling the gun when the implosion happened.

Here is the sequence of of what I did right before I heard a pop inside the Tuxing tube.

1. Hooked everything up, started water pump, and started Yong Heng pump.

2. Charged FX Dream pup air cylinder pressure from 140 to 225 bar.

3. Turned off the Yong Heng pump.

4. Opened the pressure release valve on Yong Heng pump. I didn’t watch the pressure gauge, but line pressure was apparently coming down slowly which I didn’t know. I must not have open the valve wide enough.

5. Disconnected the black filter housing (hose directly coming out of Yong Heng) from Tuxing Separator. There was a loud pressure escaping sound, and heard quiet pop inside the Tuxing pipe.

Opened up the Tuxing separator and saw that active charcoals closest to the Yong Heng pump end were compressed and caked up towards the opening (side where I disconnected the black filter housing from Tuxing).

I am wondering if active charcoals got wet and blocked the opening, and that caused something funny with the pressure difference when I disconnected the pressured line.

What went wrong here? Is disconnecting pressurized line a big no no? I’m still learning...

Question?

How can I prevent this from happening again? Simply make sure to release the line pressure before disconnecting?

Rebuild:

1. For better moisture control, I would like to add silica filter on the intake side of the Yong Zheng pump.

2. For Tuxing internal, I saw others create desiccant container pipe out of 1” PVC pipe with molecular sieve blocked off by cotton filter. I hear silica performs better than molecular sieve when the humidity is over 20%. I am thinking about doing half silica and half molecular sieve.

3. I am considering adding another Tuxing separator that only contains the cotton filter to make sure that I have a full control of the moisture build up.

PCP money pit sink hole is keep sucking in my money...

Well, this happened today:

Below is my pump setup:

Everything you see in this picture are pretty much new. It was only the second time directly filling the gun when the implosion happened.

Here is the sequence of of what I did right before I heard a pop inside the Tuxing tube.

1. Hooked everything up, started water pump, and started Yong Heng pump.

2. Charged FX Dream pup air cylinder pressure from 140 to 225 bar.

3. Turned off the Yong Heng pump.

4. Opened the pressure release valve on Yong Heng pump. I didn’t watch the pressure gauge, but line pressure was apparently coming down slowly which I didn’t know. I must not have open the valve wide enough.

5. Disconnected the black filter housing (hose directly coming out of Yong Heng) from Tuxing Separator. There was a loud pressure escaping sound, and heard quiet pop inside the Tuxing pipe.

Opened up the Tuxing separator and saw that active charcoals closest to the Yong Heng pump end were compressed and caked up towards the opening (side where I disconnected the black filter housing from Tuxing).

I am wondering if active charcoals got wet and blocked the opening, and that caused something funny with the pressure difference when I disconnected the pressured line.

What went wrong here? Is disconnecting pressurized line a big no no? I’m still learning...

Question?

How can I prevent this from happening again? Simply make sure to release the line pressure before disconnecting?

Rebuild:

1. For better moisture control, I would like to add silica filter on the intake side of the Yong Zheng pump.

2. For Tuxing internal, I saw others create desiccant container pipe out of 1” PVC pipe with molecular sieve blocked off by cotton filter. I hear silica performs better than molecular sieve when the humidity is over 20%. I am thinking about doing half silica and half molecular sieve.

3. I am considering adding another Tuxing separator that only contains the cotton filter to make sure that I have a full control of the moisture build up.

PCP money pit sink hole is keep sucking in my money...