@SigP220- payment for parts was done thru PayPal, and it took just under 3 weeks to get to me.

So, to summarize all of this(I was tied up with my son most of the evening helping him qualify for his very own first car loan, lol) this is what I would do, knowing what I know now:

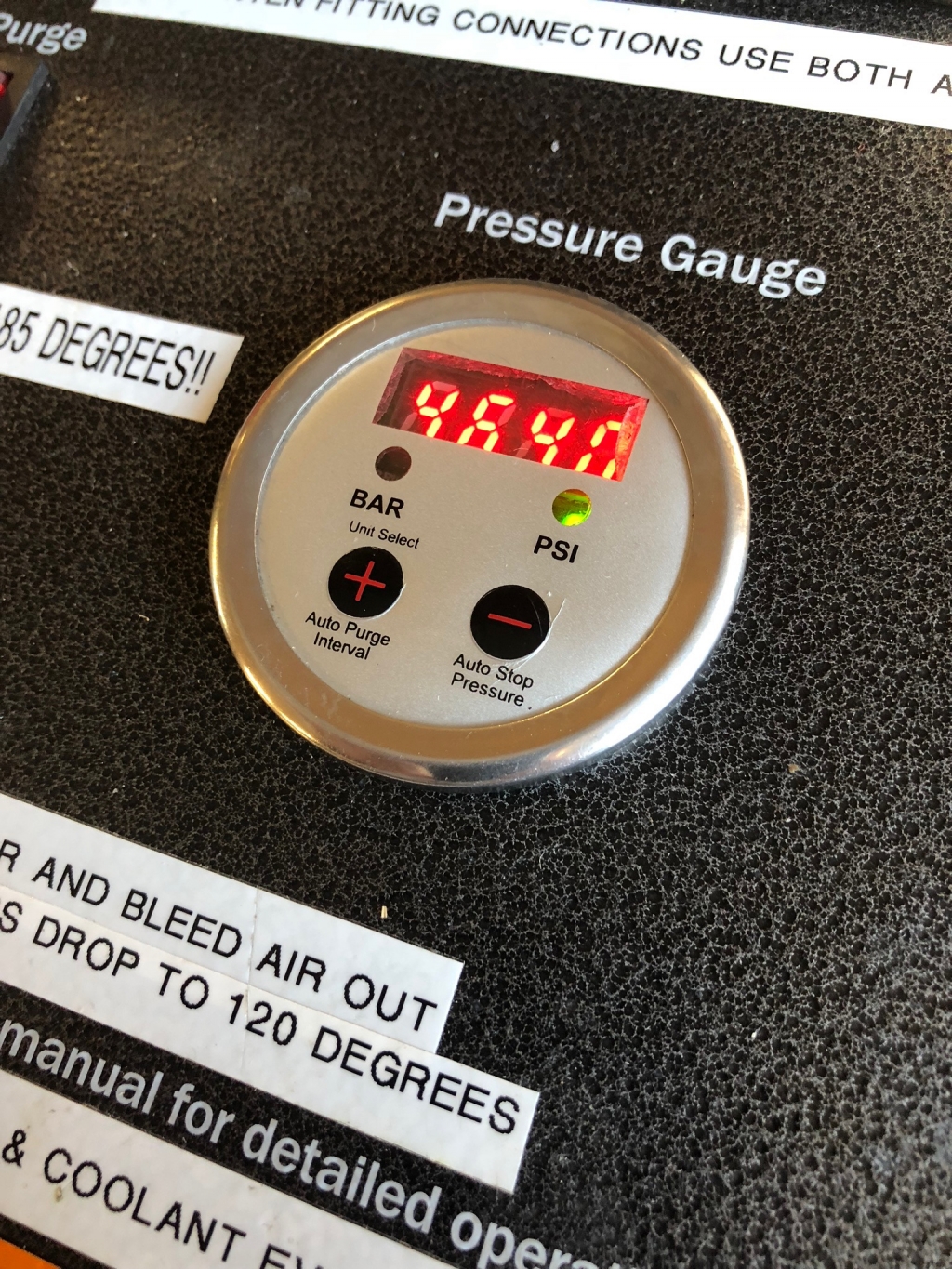

Check all the easy things first, like the two check valves. One is at the discharge line coming out of the second stage high pressure head, and the second one is at the intake connection at the aluminum desiccant block that your fill whip is connected to. Run a test(see note below about draining the coolant). If still no pressure build up after the check valves have been changed out or cleaned out, follow steps 1 thru 3. This is all assuming you’re having this problem of no pressure build up and you are 100% leak free at all connections.

1. Remove the entire second stage high pressure cylinder piece by piece, just so you can see if there is pitting in any of the aluminum parts. That’s a total of 4 long bolts, and 4 short ones, all 5mm Allen. Any signs of pitting, just stop, remove the four short bolts at the bottom of the cylinder head flange, set that head aside, and just order a brand new head assembly from Tuxing. In the link in my last post I went ahead and put all the parts that I ordered in my cart, so you know exactly what to get.

2. On the o ring seal kit, I was unsure if the check valve springs included in the kit matched what came in the hatsan kit, if you haven’t dove into your hatsan kit, you don’t need to order this o ring kit. If you already have, or want a spare kit, make sure and copy and paste that kit I have pictured above and message Tuxing thru email that you want this exact kit, and copy and paste this kit on your email.

3. The gasket set- it comes with the one gasket you’ll need for the high pressure second stage to seal up your new head, and will also include the two you will need for the first stage head along with that stainless reed blade, and the two tiny rods to hang that reed blade. Even if yours still looks good, change it out.

I found a lot of carbon type crud in the section of the first stage that has the embossed V shape, that’s in my second to last post, first pic. Clean that all up along with the aluminum mating parts with a scotch brite pad, and wash everything up with a cleaner degreaser solution.

When scraping off all the old paper gasket material on both heads, please shove a shop towel or piece of paper towel into the cylinder so that debris does not get caught up on top of the inner piston cylinder. I would buy some gasket remover from the auto parts store, as it makes scraping the old gasket much easier. Finally, take your shop compressor or canned air and blow all debris away from the entire cylinder areas. Clean is king here for sure.

Heres another final tip- prior to even opening anything up, drain all your coolant out and just plan on replacing all of that with new. When you disconnect the cylinder heads you’ll have coolant all over, and it makes a big mess, especially if your using anti freeze in the mix. When your all bolted back up, just run clean, fresh water thru the system to flush out the old coolant remains during your testing procedure. If you have to reopen anything, all you’ll have spilling all over is plain water, instead of slimy coolant. If all checks out ok and your compressor is all like new again, drain the water, replace with the coolant and distilled water as spec’d out by hatsan, and plan on changing out the oil for new.

While you’re at it, change out the tampon filter in the coolant tower, along with the desiccant beads in the aluminum block. Your hatsan o ring kit along with the o ring kit from Tuxing will have the green Viton O rings for these areas.

Awhile back, I posted my maintenance filter replacement here on this forum. The correct desiccant beads for the desiccant block is ACTIVATED ALUMINA, as told to me by Hatsan, and can be purchased from amazon. Do a search on my post, as I’ve also well documented that maintenance procedure step by step with pics.

By doing all all of this, your compressor will be like new again, ready to take on many many tank top offs.

After I change out that hard line that’s leaking, I’m gonna clean this thing all up from the coolant spill marks, and put this compressor up for sale. I will have enough o rings, piston seals, and gaskets to do two or three more rebuilds. Only reason I’m selling is to replenish my bank account from the used Alkin I just recently purchased. I am totally confident now with all the work I’ve put into it along with new parts, it is in near new condition with just under 15 hours of use on it.