I recently received this nice Diana 52 stock:

However, this was a concern:

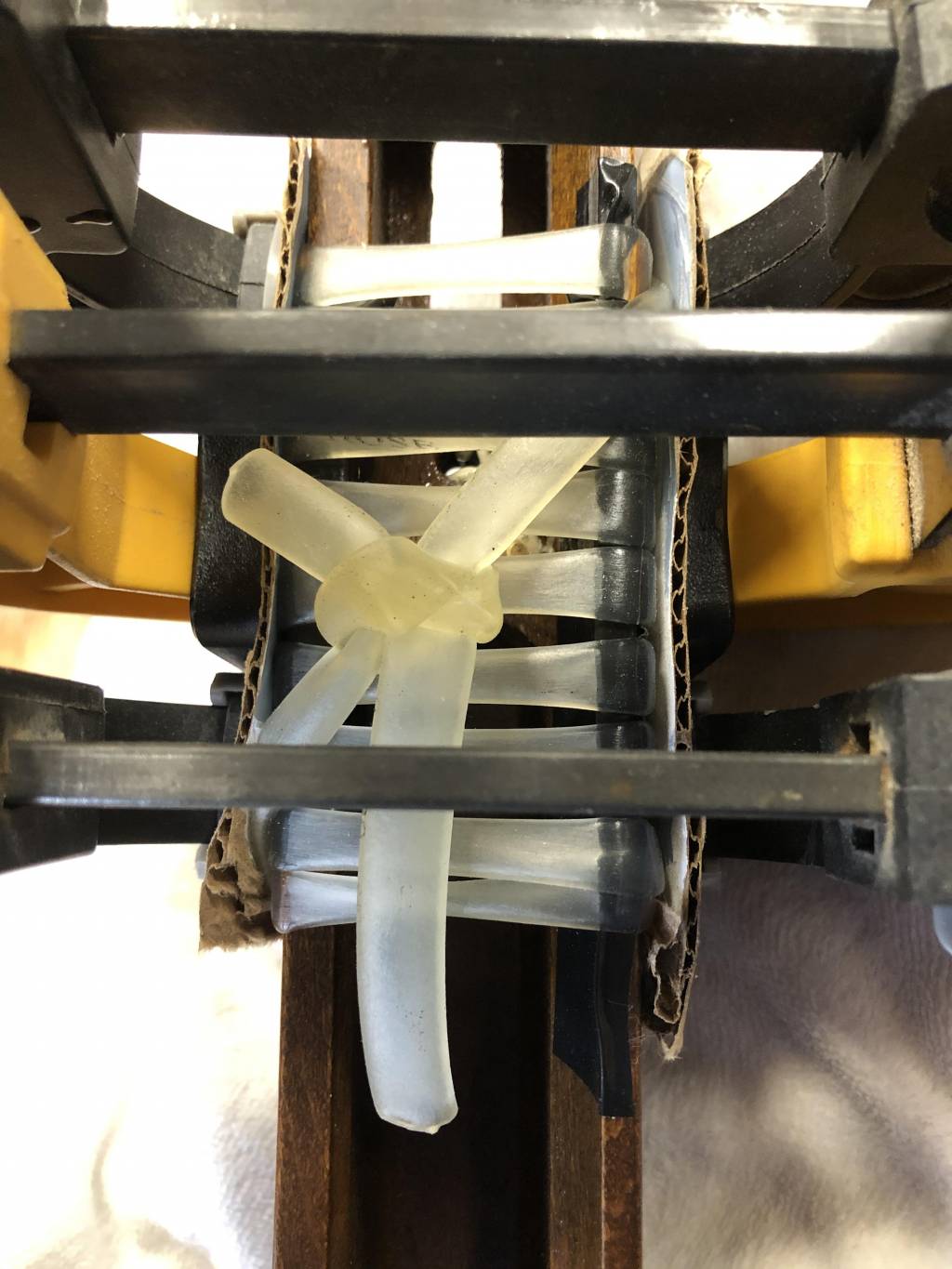

Where there's a will, there's a way. Time to make it happen:

Fire spitting Diana 48 .20 (D48 .20 #2) action, performing strong at 21+ fpe with JSB 13.73 gn pellets: into the stock for a welcoming stress test.

Fire spitting Diana 48 .20 (D48 .20 #2) action, performing strong at 21+ fpe with JSB 13.73 gn pellets: into the stock for a welcoming stress test.

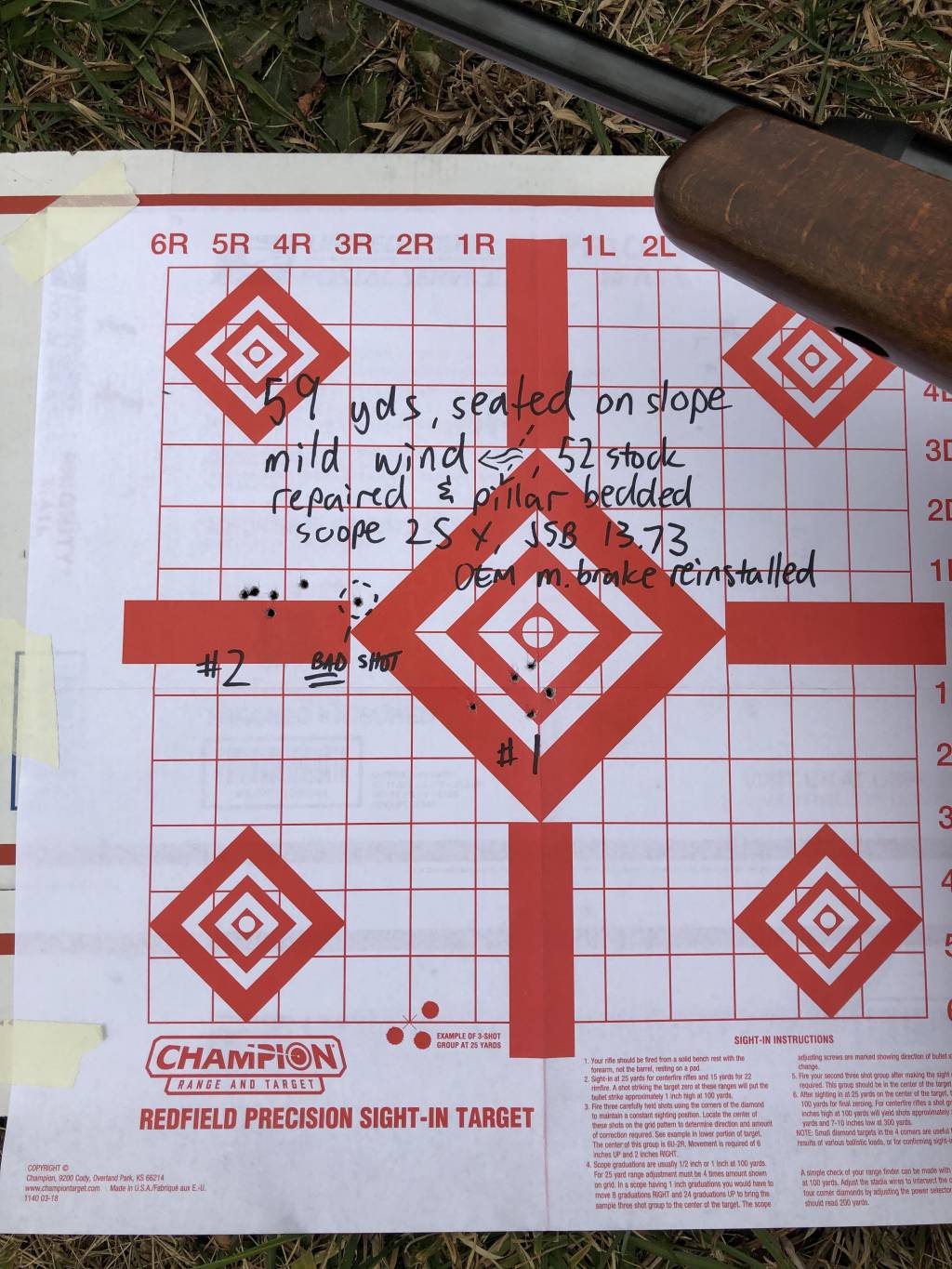

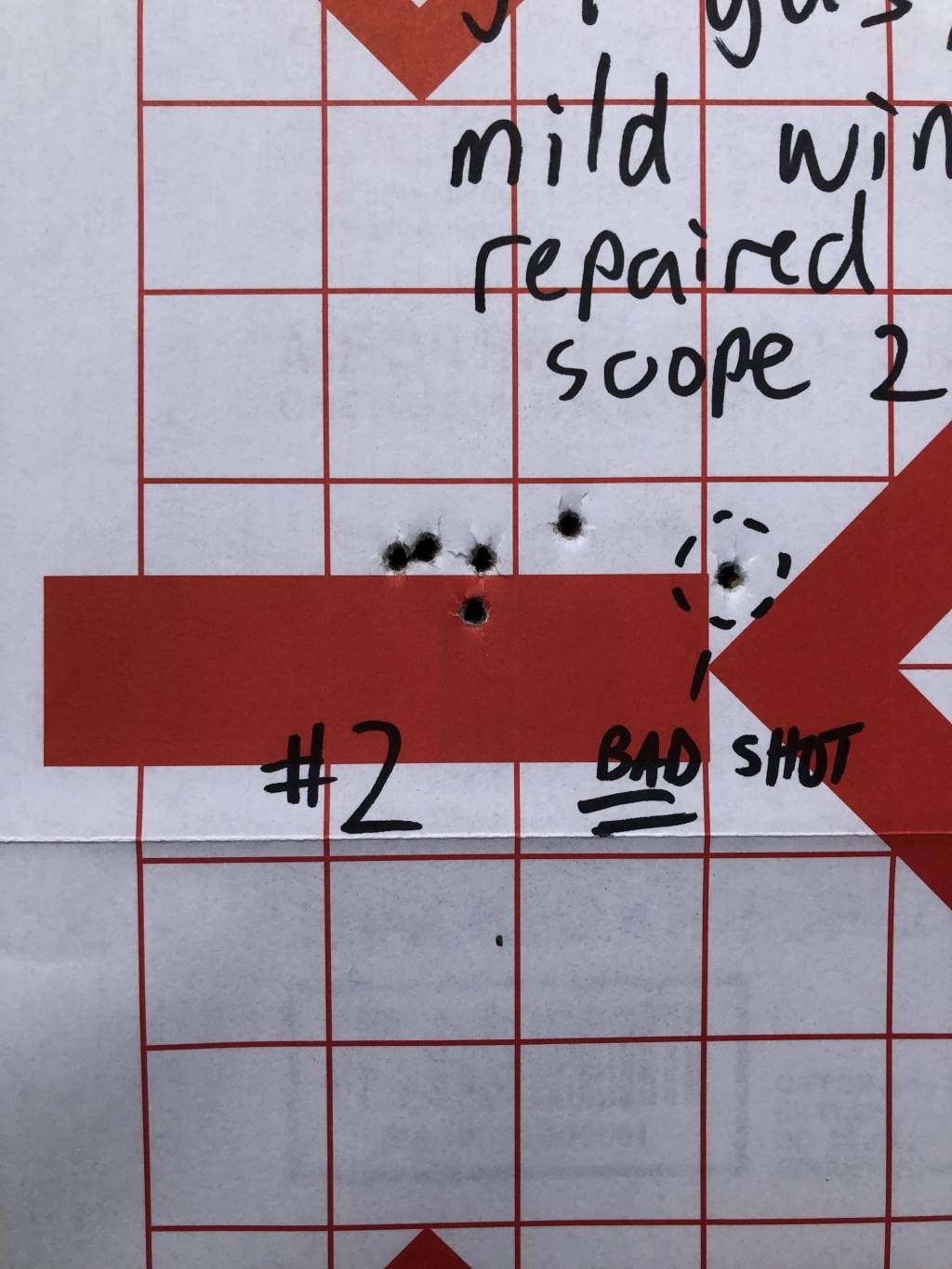

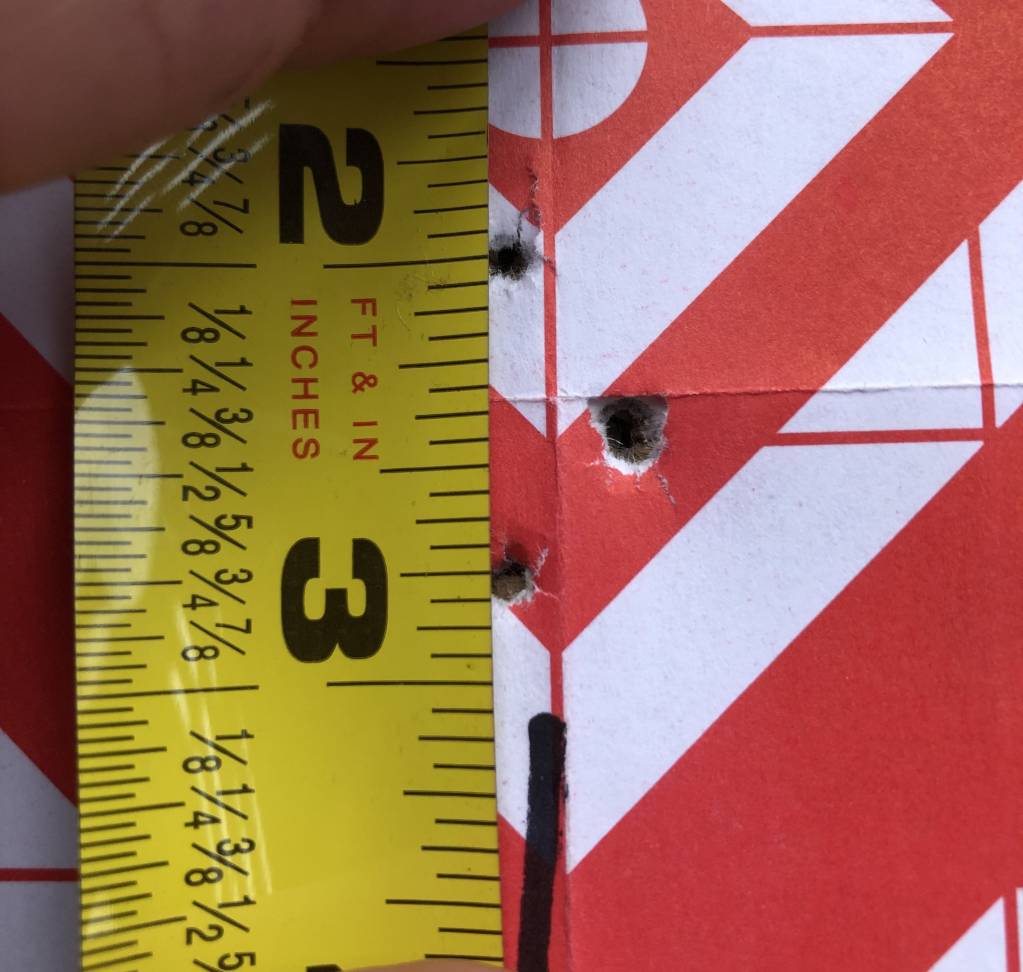

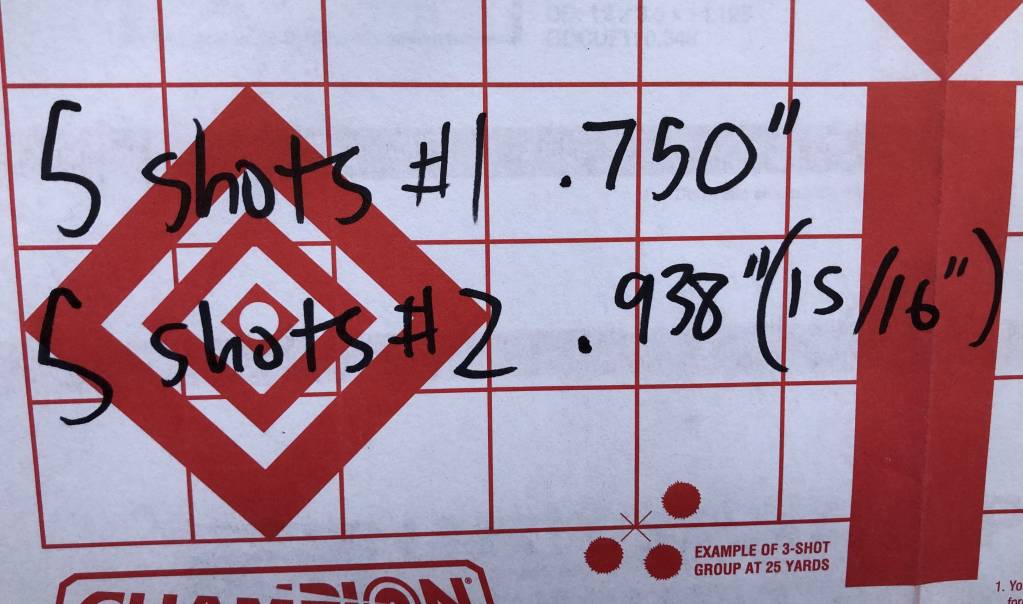

Here are the inaugural groups with my new to me D52 stock, now repaired and improved upon. 59 yards seated, shooting across the slope:

* Fine threaded pitch brass machine screws with grounded/pointed tips, each one angled in from opposite side of crack, Gorilla Glue in pilot holes and on screw threads, after cured the screws were filed/sanded flush with wood

*

Gorilla Glue flossed through cracks and applied over crack surfaces, 30+ hour cure time

Gorilla Glue flossed through cracks and applied over crack surfaces, 30+ hour cure time

* steel pillar through fwd trigger guard stock hole ground/sanded to height and meticulously bedded

*Gray Marine-Tex (compressive strength over 13,000 PSI) for pillar bedding and inletting bedding over repaired surface, 36 hour cure time

No more concerns. I've gained confidence to tackle more stock related projects such as: pillar bedding/stock bedding/structural repairs. Good stuff all around.

Thanks for letting me share! I hope this can be of help.

JohnnyPiston

However, this was a concern:

Where there's a will, there's a way. Time to make it happen:

Here are the inaugural groups with my new to me D52 stock, now repaired and improved upon. 59 yards seated, shooting across the slope:

* Fine threaded pitch brass machine screws with grounded/pointed tips, each one angled in from opposite side of crack, Gorilla Glue in pilot holes and on screw threads, after cured the screws were filed/sanded flush with wood

*

* steel pillar through fwd trigger guard stock hole ground/sanded to height and meticulously bedded

*Gray Marine-Tex (compressive strength over 13,000 PSI) for pillar bedding and inletting bedding over repaired surface, 36 hour cure time

No more concerns. I've gained confidence to tackle more stock related projects such as: pillar bedding/stock bedding/structural repairs. Good stuff all around.

Thanks for letting me share! I hope this can be of help.

JohnnyPiston