The fat bastard had a little money to spend and loads of time to spare so be warned!

So i set out to find out what the Altaros booster actually can/will do.

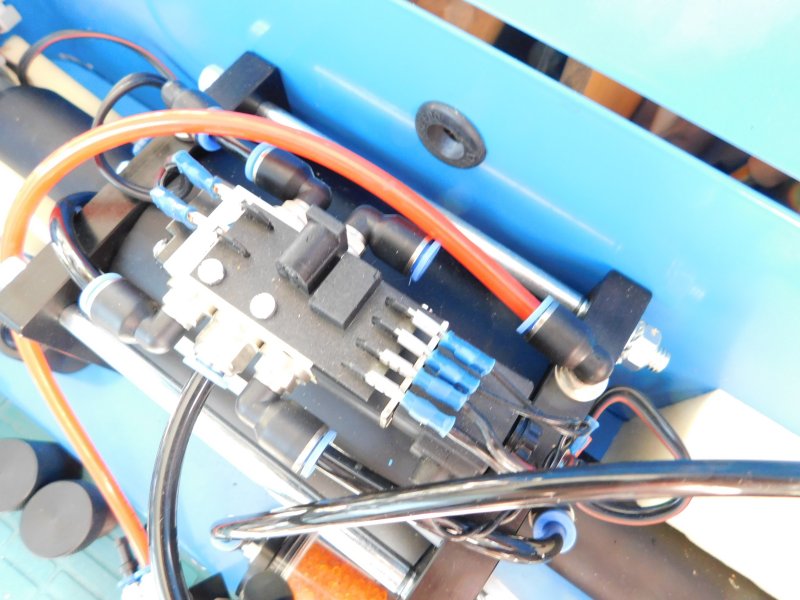

A bag of pneumatic fittings and some hose later and the fun begins.

As of now there is 5 distinct ways to run the booster and get HPA in the end.

1) As per ususal from a shop compressor.

2) When the main piston is driven by shop compressor but the low pressure inlet is fed from a HPA tank or Nitrogen does’nt matter as long as it is fed more than @5bar-75psi and max. 10bar-145psi. Most usefull for most running Nitrogen and want the most for their bucks!

Suck those expensive bottles dry before returning.

3) When the intire booster is run by bottled air or a split of air for waste piston work and Nitrogen to be compressed. Same pressures as stated above (use air, compress Nitrogen).

4) When the main piston is driven by shop air and @100bar-1450psi air or Nitrogen is fed directly into the HP cylinder (Altaros supplies all fittings for $30’ish). The HP regulator is another $130'ish.

5) As a true booster. I have fed the 10bar-145psi air through a manual flip-flop valve and directly into the compression side of the main piston. When 100bar-1450psi is supplied to the HP cylinder the booster will work 1 cycle at every press of the button. 2 bottles used one for driving, LP air, and one for compressible HP air or Nitrogen. The seal at the bottom of the LP piston leaks so a stop peg is needed or the loose hose will leak badly.

That’s ”jailbreaking” the Altaros and making the most out of it.

I bought at least 5 times the fittings used + 6m-7yds of 6mm hose and it cost me some €30-$35 including (shipping), the manual flip-flop valve and some pressure regulators.

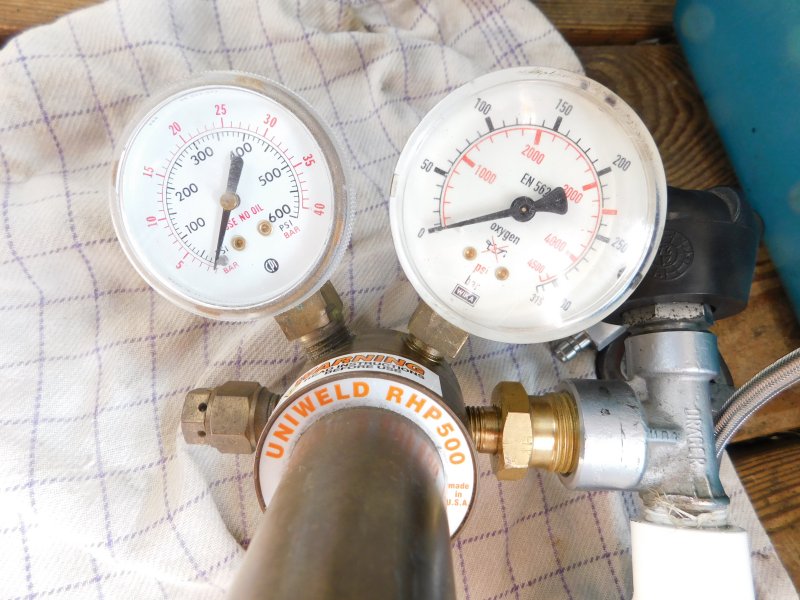

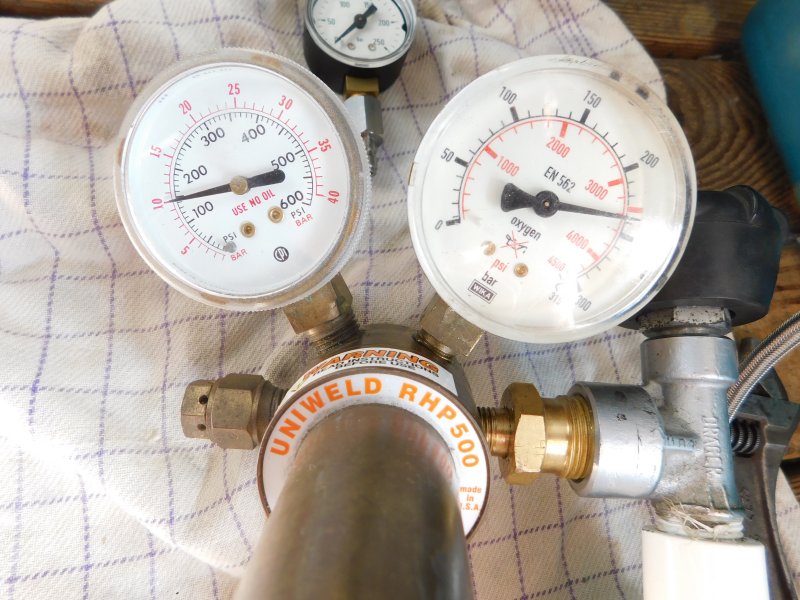

Solution 2 depicted

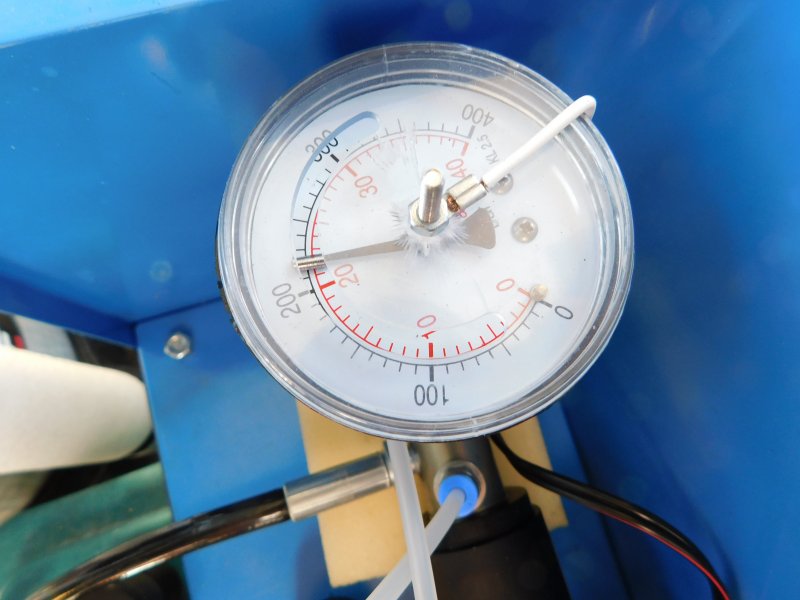

Standard Nitrogen shop regulator that i modified to fit the DIN of SCUBA tanks. 0-400psi and perfect to feed 10bar-145psi for the booster. These can be had for a song and a dance at welding shops. Mine was 1/4BSP on the inlet and fixed with some extreme sealant, i mean it was like moving a mountain to get it loose even using heat. Not to much as there are lots of delicate regulator thingies and seals inside that regulator and you want those to work later on!

Maybe a machine shop will provide an adaptor from your Nitrogen standard (0.965"-14 NGO) to 5/8"NPT (DIN 200/300) for cold beer?

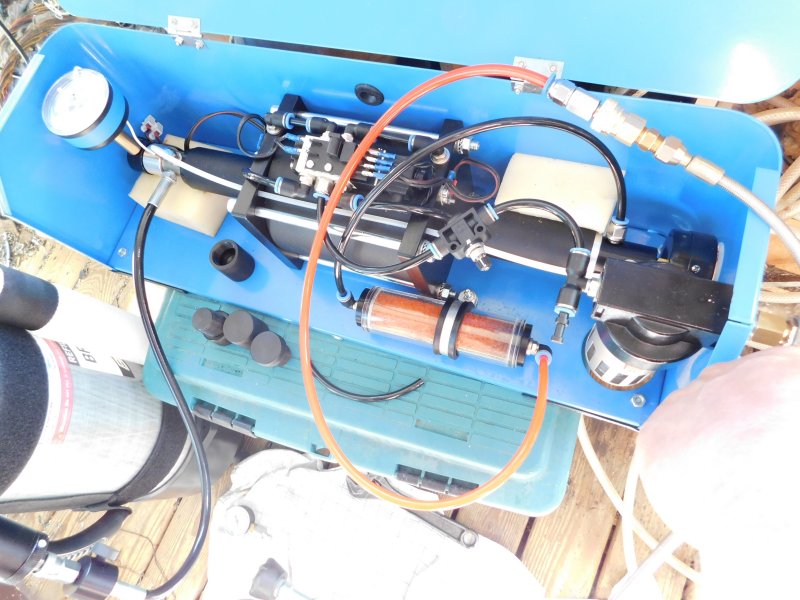

HP air all set for use.

Coupled directly to the LP inlet and now feeding bottled air or Nitrogen through the dryer.

All fittings needed to do the stunt. Foster - 1/8"BSP female fitting, 1/8" male to 6mm pneumatic fitting, stop peg and some 6mm hose.

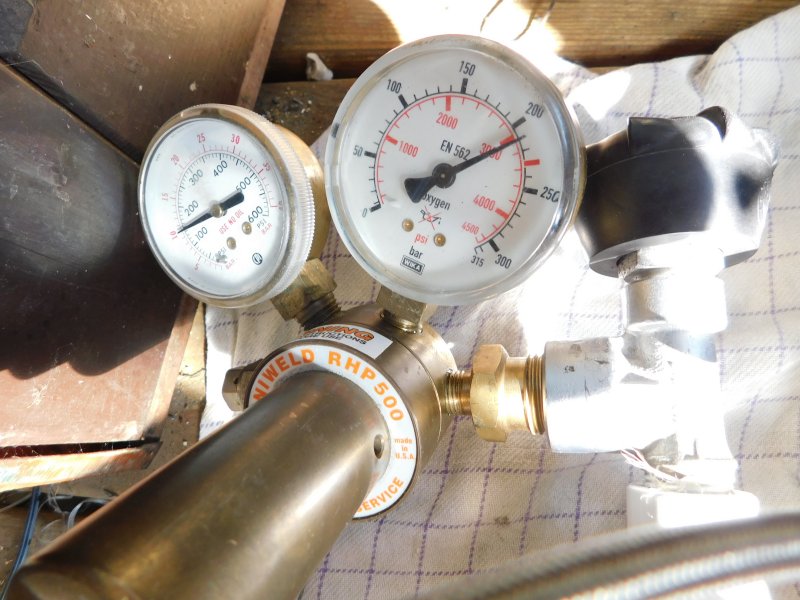

Solution 4 depicted

Lp air for driving the main piston (wasted air)

HP air / Nitrogen for use/compression.

LP air fed through a flip-flop manual valve feeding the compression side of the main piston.

Remember to plug the outlet of the LP cylinder as the bottom seal leaks bad the wrong way ;-)

Plug the unused valve side to stop wasting air.

Inlet for compressing the HP side of the main cylinder.

I think 5 strokes of the valve got me 80bar-1150psi in my hoses and Gold filter.

What think you?

So i set out to find out what the Altaros booster actually can/will do.

A bag of pneumatic fittings and some hose later and the fun begins.

As of now there is 5 distinct ways to run the booster and get HPA in the end.

1) As per ususal from a shop compressor.

2) When the main piston is driven by shop compressor but the low pressure inlet is fed from a HPA tank or Nitrogen does’nt matter as long as it is fed more than @5bar-75psi and max. 10bar-145psi. Most usefull for most running Nitrogen and want the most for their bucks!

Suck those expensive bottles dry before returning.

3) When the intire booster is run by bottled air or a split of air for waste piston work and Nitrogen to be compressed. Same pressures as stated above (use air, compress Nitrogen).

4) When the main piston is driven by shop air and @100bar-1450psi air or Nitrogen is fed directly into the HP cylinder (Altaros supplies all fittings for $30’ish). The HP regulator is another $130'ish.

5) As a true booster. I have fed the 10bar-145psi air through a manual flip-flop valve and directly into the compression side of the main piston. When 100bar-1450psi is supplied to the HP cylinder the booster will work 1 cycle at every press of the button. 2 bottles used one for driving, LP air, and one for compressible HP air or Nitrogen. The seal at the bottom of the LP piston leaks so a stop peg is needed or the loose hose will leak badly.

That’s ”jailbreaking” the Altaros and making the most out of it.

I bought at least 5 times the fittings used + 6m-7yds of 6mm hose and it cost me some €30-$35 including (shipping), the manual flip-flop valve and some pressure regulators.

Solution 2 depicted

Standard Nitrogen shop regulator that i modified to fit the DIN of SCUBA tanks. 0-400psi and perfect to feed 10bar-145psi for the booster. These can be had for a song and a dance at welding shops. Mine was 1/4BSP on the inlet and fixed with some extreme sealant, i mean it was like moving a mountain to get it loose even using heat. Not to much as there are lots of delicate regulator thingies and seals inside that regulator and you want those to work later on!

Maybe a machine shop will provide an adaptor from your Nitrogen standard (0.965"-14 NGO) to 5/8"NPT (DIN 200/300) for cold beer?

HP air all set for use.

Coupled directly to the LP inlet and now feeding bottled air or Nitrogen through the dryer.

All fittings needed to do the stunt. Foster - 1/8"BSP female fitting, 1/8" male to 6mm pneumatic fitting, stop peg and some 6mm hose.

Solution 4 depicted

Lp air for driving the main piston (wasted air)

HP air / Nitrogen for use/compression.

LP air fed through a flip-flop manual valve feeding the compression side of the main piston.

Remember to plug the outlet of the LP cylinder as the bottom seal leaks bad the wrong way ;-)

Plug the unused valve side to stop wasting air.

Inlet for compressing the HP side of the main cylinder.

I think 5 strokes of the valve got me 80bar-1150psi in my hoses and Gold filter.

What think you?