While reading the handy flier that AOA includes with new air guns, they suggest shootIng pellets that were lubricated with either FP-10, Slick 50 or Napier Power Pellet Lube none of which I had on hand. So I had some free time today and thought I would test a few lubricants that may or may not work to lubricate pellets.

Here are a few of the oils I tested:

My testing procedure went as follows;

- Wash pellets with Naptha and dry thoroughly

- Thoroughly clean the barrel with Slip 2000 #725 de-greaser and gun cleaner.

- Place 20 clean pellets in a baggie and add 3 drops of lubricant and thoroughly coat the pellets.

- Shoot 20 pellets over a Competition Electronics Pro-Chrono and record average velocity, spread and standard deviation.

- I used my new Brocock Sniper XR .22

- After shooting 20 pellets, run two wet patches of #725 through the barrel followed by X number of dry patches until clean.

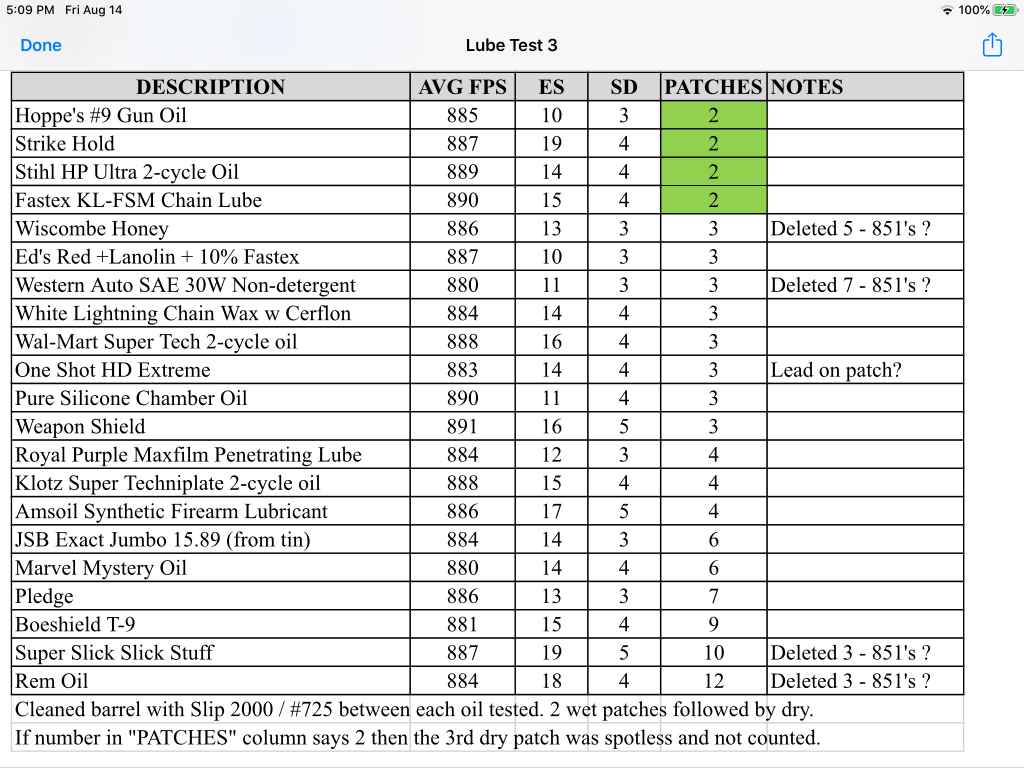

(If there is a 2 in the “PATCHES” column that means the third patch was perfectly clean and was not counted.) The lower number would indicate it prevented wear better than a higher number.

This was only a preliminary test with more to follow. In my mind, it would be important to choose an oil that has a superior film strength. Film strength is one characteristic of a lubricant to provide a thin film of oil between two surfaces and keep them separated. Theoretically if the two metal parts never touch there would never be any wear. The higher the film strength the less chance that wear would occur. If the film of oil fails then wear would occur and would likely show during the post shooting cleaning. The more wear the more wear particles (lead) would show up on the dry patches. The higher the number of patches the more wear and the less effective the oil would be. I highlighted in GREEN, on the above chart, the oils with the lowest number of patches that were used to clean the barrel. The less patches that were used, the more effective the oil was at preventing wear. I realize that we want a small amount of lead to be deposited on the barrel’s inner surfaces. On the plus side, the lower number might represent longer shooting before it would require cleaning or possibly less accuracy degradation?

There also seems to be a correlation between lower patch numbers and higher velocity numbers which may mean better efficiency?

An oddity that I can’t explain was I had some weird 851 velocities pop up unexpectedly on a few of the oils.I don’t know if it was a factor of the oil or if they were bad or undersized pellets?

My next step is take some of the better performers and shoot some groups at different distances to see if there is any positive or negative effect on accuracy and group size. This will take some time so I will update this thread as I learn more information.

Here are a few of the oils I tested:

My testing procedure went as follows;

- Wash pellets with Naptha and dry thoroughly

- Thoroughly clean the barrel with Slip 2000 #725 de-greaser and gun cleaner.

- Place 20 clean pellets in a baggie and add 3 drops of lubricant and thoroughly coat the pellets.

- Shoot 20 pellets over a Competition Electronics Pro-Chrono and record average velocity, spread and standard deviation.

- I used my new Brocock Sniper XR .22

- After shooting 20 pellets, run two wet patches of #725 through the barrel followed by X number of dry patches until clean.

(If there is a 2 in the “PATCHES” column that means the third patch was perfectly clean and was not counted.) The lower number would indicate it prevented wear better than a higher number.

This was only a preliminary test with more to follow. In my mind, it would be important to choose an oil that has a superior film strength. Film strength is one characteristic of a lubricant to provide a thin film of oil between two surfaces and keep them separated. Theoretically if the two metal parts never touch there would never be any wear. The higher the film strength the less chance that wear would occur. If the film of oil fails then wear would occur and would likely show during the post shooting cleaning. The more wear the more wear particles (lead) would show up on the dry patches. The higher the number of patches the more wear and the less effective the oil would be. I highlighted in GREEN, on the above chart, the oils with the lowest number of patches that were used to clean the barrel. The less patches that were used, the more effective the oil was at preventing wear. I realize that we want a small amount of lead to be deposited on the barrel’s inner surfaces. On the plus side, the lower number might represent longer shooting before it would require cleaning or possibly less accuracy degradation?

There also seems to be a correlation between lower patch numbers and higher velocity numbers which may mean better efficiency?

An oddity that I can’t explain was I had some weird 851 velocities pop up unexpectedly on a few of the oils.I don’t know if it was a factor of the oil or if they were bad or undersized pellets?

My next step is take some of the better performers and shoot some groups at different distances to see if there is any positive or negative effect on accuracy and group size. This will take some time so I will update this thread as I learn more information.