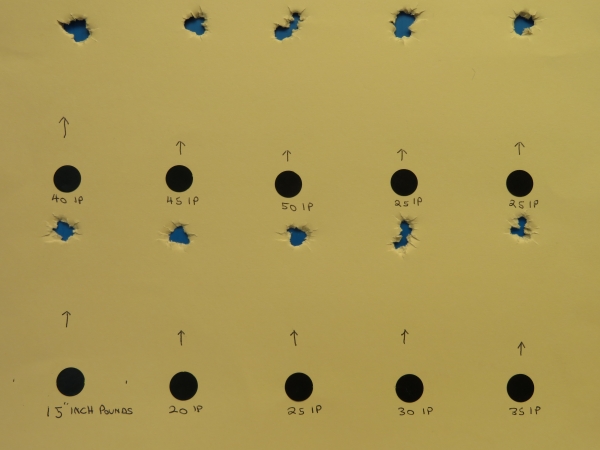

I was wondering if the tension applied to the barrel liner with the front nut would affect the barrel harmonics when fired. I made a socket to fit the nut and then took my inch pound torque wrench and started to test. First I removed the shroud and moderator and backed of the liner retaining nut. Then applied torque to 15 inch pounds and reinstalled shroud and moderator to where they stopped with no extreme tightness applied. I adjusted the scope so my point of aim was about 3 inches low to pellet strike this was done at 25 yards I then fired 5 shots and removed shroud and moderator and torqued barrel to 20 inch pounds and reinstalled the shroud and moderator and shot 5 more rounds.

I did the same procedure in 5 inch pound increments up to 50 inch pounds. The 50 ip seemed very tight and felt that was as high as I wanted to go for now. Here are the results.

The point of impact moved up from 2.700 to 2.080 between 15ip to 40ip at 45 it moved up to 2.945 and at 50 it moved to 3.050 ip. I then dropped the torque back to 25ip and shot 2 more groups and found that the poi stayed the same as the 50ip setting. I guess the barrel seated at the high torque and stayed there. I seemed to get better groups at 25ip setting. I think that there is enough change to take it to the 50 and 100 yard range to see if it really makes a difference. This was done on the bypod when I go to the 100 I will use a rifle rest.

I did the same procedure in 5 inch pound increments up to 50 inch pounds. The 50 ip seemed very tight and felt that was as high as I wanted to go for now. Here are the results.

The point of impact moved up from 2.700 to 2.080 between 15ip to 40ip at 45 it moved up to 2.945 and at 50 it moved to 3.050 ip. I then dropped the torque back to 25ip and shot 2 more groups and found that the poi stayed the same as the 50ip setting. I guess the barrel seated at the high torque and stayed there. I seemed to get better groups at 25ip setting. I think that there is enough change to take it to the 50 and 100 yard range to see if it really makes a difference. This was done on the bypod when I go to the 100 I will use a rifle rest.