Anyone use this or the machined rods with points on them? I could see it showing that factory tap and drilled mounts may be off as mass produced things are at times. Yet, wouldn't the fact that the tube is stiff overcome at least the very smallest differences between the two spaces? It looks like a neat thing to try to show just how true mounts and rings are, maybe test a $10 set VS a SportsMatch?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

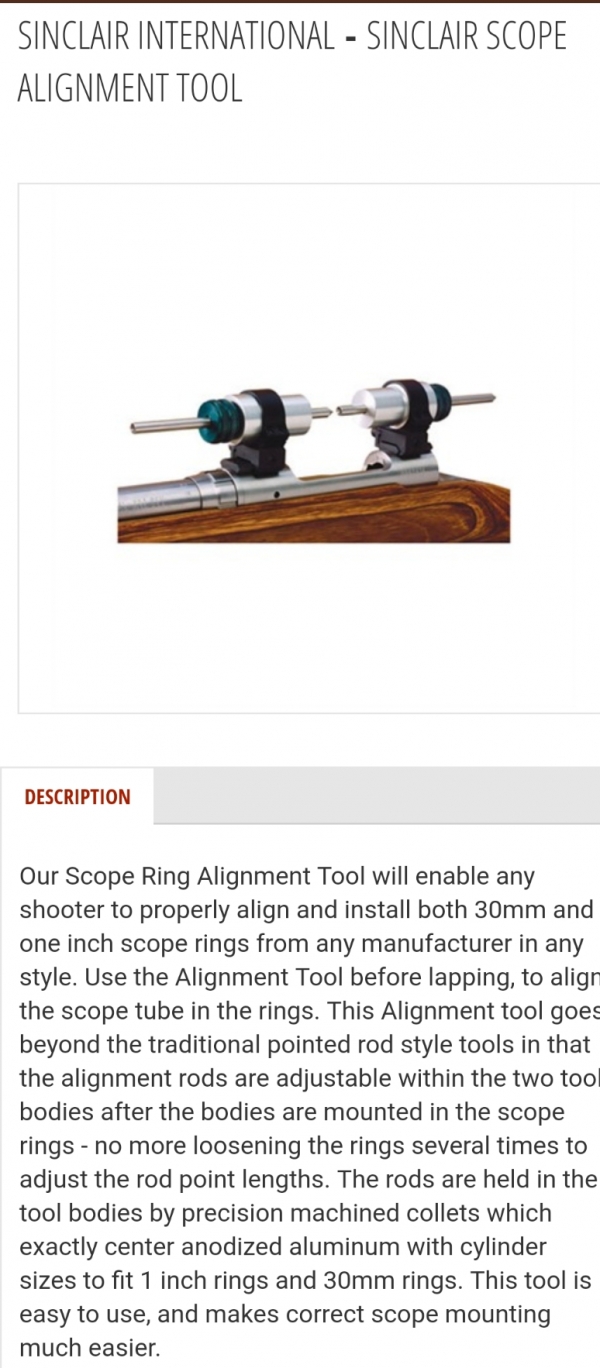

Sinclair Mount Tool

- Thread starter DuncanHynes

- Start date

The way I see it, a tool like this makes sense for powderburners that are fitted with rings that are screwed into the receiver.

However the vast majority of airguns have a rail that is machined along each side in one pass, thus any lack of straightness is vanishingly small. Similarly, most rings are extruded aluminum and are therefore well matched.

Note none of this has to do with alignment between the scope and the barrel...that’s a whole different subject.

Regarding lapping rings, the one airgun scenario where I think it is sometimes beneficial is for a hard-recoiling springer. It is not necessary for other powerplants.

However the vast majority of airguns have a rail that is machined along each side in one pass, thus any lack of straightness is vanishingly small. Similarly, most rings are extruded aluminum and are therefore well matched.

Note none of this has to do with alignment between the scope and the barrel...that’s a whole different subject.

Regarding lapping rings, the one airgun scenario where I think it is sometimes beneficial is for a hard-recoiling springer. It is not necessary for other powerplants.

Upvote 0

I’m a big fan of Sinclair’s products, and I own this tool. I have since lapped every one of my rings, except whenever I use DNZ one piece mounts. What I’ve noticed with properly lapped rings, is they hardly leave mount marks on the scope, which will help in resale value of the scope should you decide to sell it later on. Especially if your one to buy inexpensive scope mounts, then you should lap them.

Upvote 0

I’m a big fan of Sinclair’s products, and I own this tool. I have since lapped every one of my rings, except whenever I use DNZ one piece mounts. What I’ve noticed with properly lapped rings, is they hardly leave mount marks on the scope, which will help in resale value of the scope should you decide to sell it later on. Especially if your one to buy inexpensive scope mounts, then you should lap them.

+1

Upvote 0

I use them and so far the pointed tips are always right on....I had the steel ones,heavy,then got a deal on some aluminum one,much better for me,I bought the whole scope mounting kit by winning a bid on ebay,saved a lot of money..I think they give you peace of mind.

Upvote 0