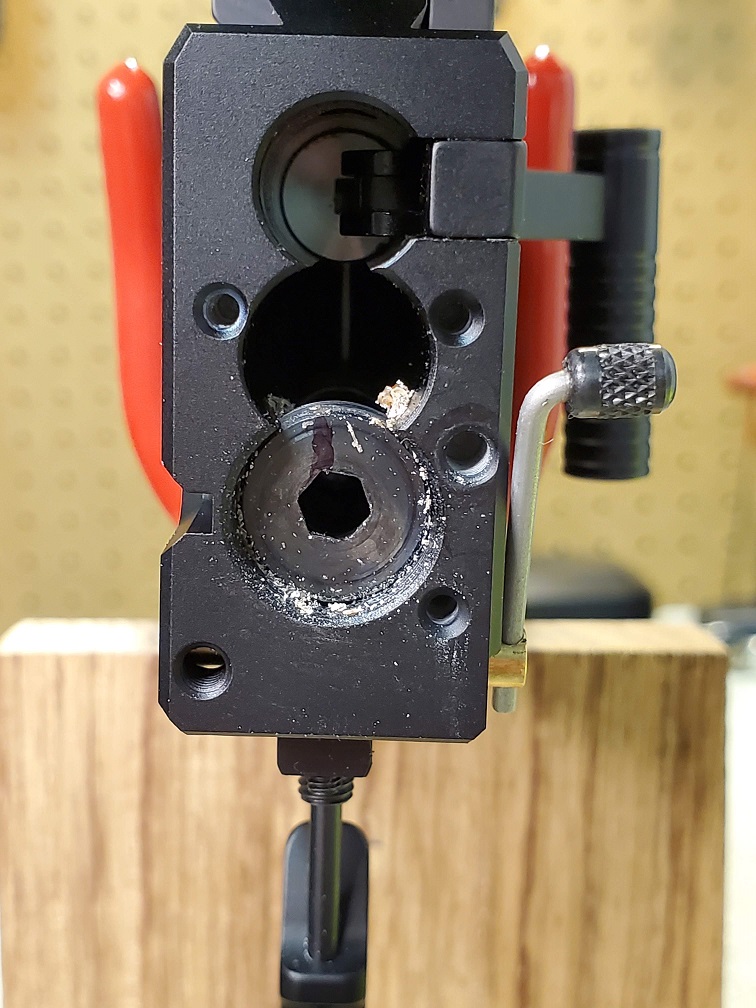

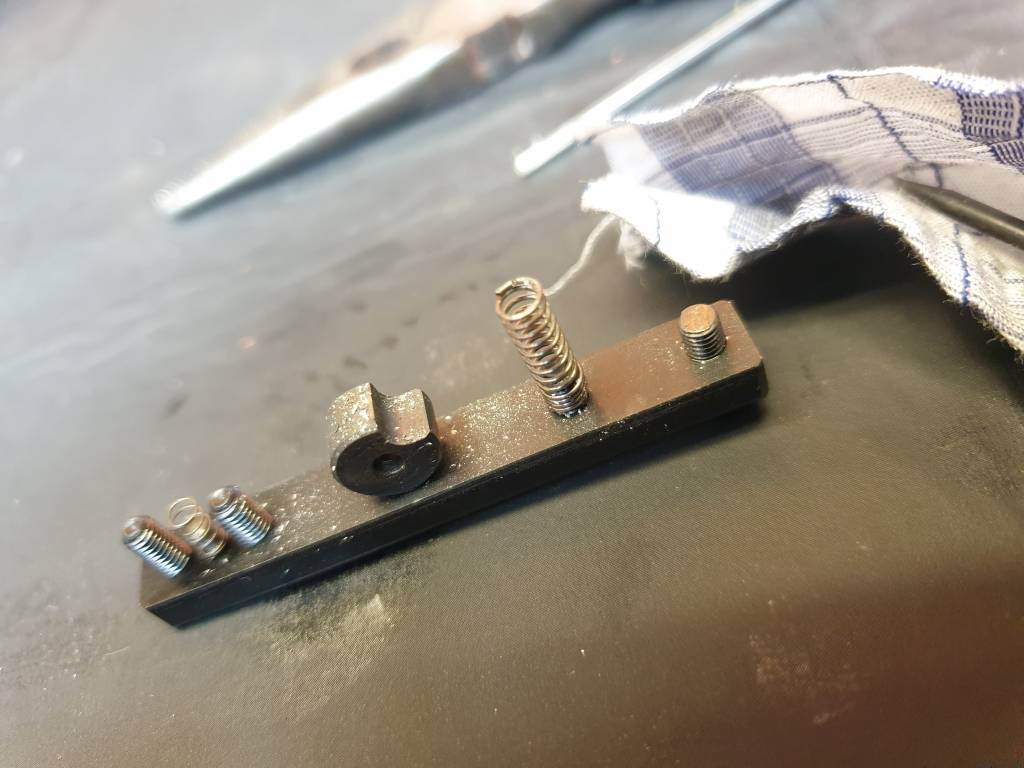

A friend asked me to look at his 1 month old Dreamline lite as it was shooting with erratic velocity. He has cranked the HST adjuster up to max to shoot slugs (.22 cal). The spring seems to be shaving filings of aluminium off of the HST adjuster body. Since the trigger is below and in front of the HST you can see in the pic how many bits have ended up on the trigger assembly. I am assuming the the velocity issues are due to the hammer becoming contaminated with Al filings. Has anyone else seen this problem with their FX?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning Shavings of HST adjuster from a dreamlite

- Thread starter xyon

- Start date

I've seen similar in my Crown. Wasnt sure where it was coming from. Cleaned, polished, and added the tiniest bit of lube and it's back to normal. I've fired close to 10000 shots thru mine, a lot at very high power output. 60-65fpe in 22 cal

Upvote 0

I saw the same in mine when I replaced the valve seat.

I took out my hammer spring shims and stuff. It still shoots a super tight string.

I took out my hammer spring shims and stuff. It still shoots a super tight string.

Upvote 0

wimpanzee is onto the problem.

I had the same shavings/Loctite in my DL Classic and the metal was coming from the Valve seat that was being destroyed from to much reg pressure (135bar) and hammers spring tension (2 turns CC from bottom). The valve seat finally broke at the weakest point at the base of the O-ring, while during that time it was filling the HS adjustment spring part of the breach full of metal shavings leading up to finally loosing air through the barrel because the seal was compromised. FX sent a free replacement under warranty. This was also a known problem with early Impacts. Problem was not solved for the Dreamline series it appears. The DL is no Impact, treat it as such. Stay within the design parameters of the platform and choose your power upgrades wisely.

Adding a Power Plenum and lowering your reg pressure giving good FPS for a variety of proper slug/pellet weights in the low/mid 900's is well within it capabilities and will save these small parts from imploding and de-stress the internals for a long trouble free life.

I had the same shavings/Loctite in my DL Classic and the metal was coming from the Valve seat that was being destroyed from to much reg pressure (135bar) and hammers spring tension (2 turns CC from bottom). The valve seat finally broke at the weakest point at the base of the O-ring, while during that time it was filling the HS adjustment spring part of the breach full of metal shavings leading up to finally loosing air through the barrel because the seal was compromised. FX sent a free replacement under warranty. This was also a known problem with early Impacts. Problem was not solved for the Dreamline series it appears. The DL is no Impact, treat it as such. Stay within the design parameters of the platform and choose your power upgrades wisely.

Adding a Power Plenum and lowering your reg pressure giving good FPS for a variety of proper slug/pellet weights in the low/mid 900's is well within it capabilities and will save these small parts from imploding and de-stress the internals for a long trouble free life.

Upvote 0

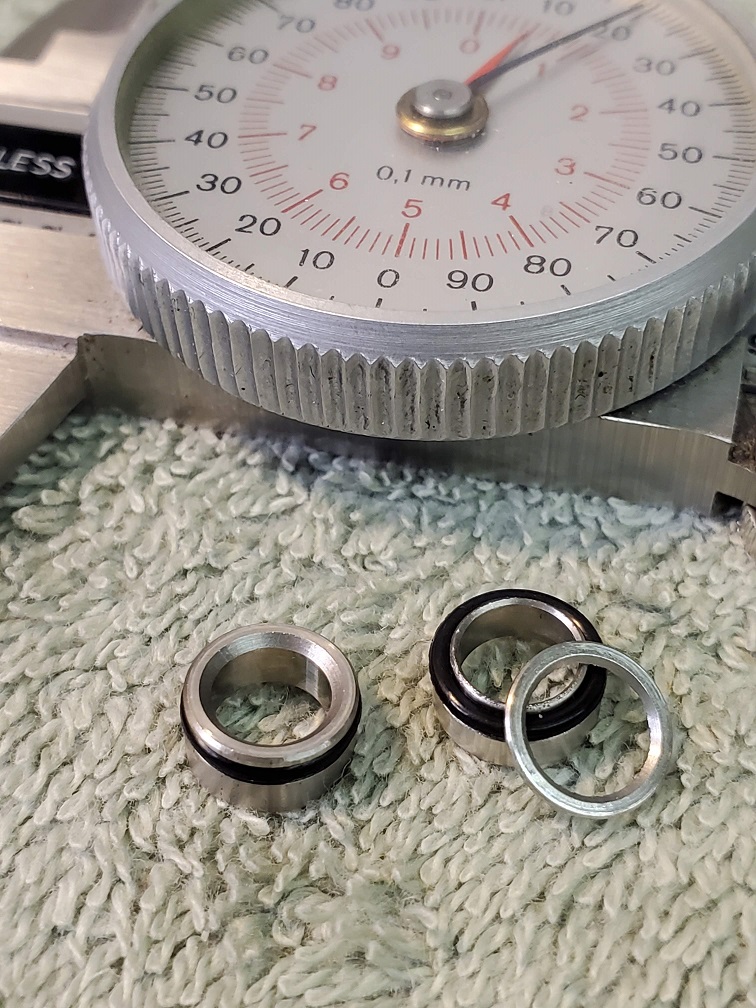

Thanks for the info guys. In the dreamline lite case there is no loctite in the hammer adjuster. It's definitely aluminium bits in there. The hammer, spring and adjuster are factory standard. The rifle has had a huma TP installed and 2 power plenums. The limit of the adjustment is dictated by screwing in the little grub screw until there is barely any free play in the hammer when the power wheel is on max. If you screw it in any further the power wheel can not be turned (without potentially damaging it) - on this rifle, this equates to balancing the hammer with a pressure of about 130 bar. (the manual says 160bar is the max)

I don't think there are any metal shavings coming from the valve, given their location mostly near the hst adjuster and very few at the valve end of the hammer.

My best guess at this point is that, as FX's run with no preload on the spring, the back end of the spring will travel forward due the overall forward momentum of the spring. The back end of the spring is quite sharp and could easily damage the aluminium as it slides by forwards and back. So I have de-burred and polished the spring ends/edges in the hope this will mitigate the problem.

I don't think there are any metal shavings coming from the valve, given their location mostly near the hst adjuster and very few at the valve end of the hammer.

My best guess at this point is that, as FX's run with no preload on the spring, the back end of the spring will travel forward due the overall forward momentum of the spring. The back end of the spring is quite sharp and could easily damage the aluminium as it slides by forwards and back. So I have de-burred and polished the spring ends/edges in the hope this will mitigate the problem.

Upvote 0

xyon, let us know if your solution solves this problem. Excellent sleuthing my friend.

Patrick

Patrick

Upvote 0

Not the same gun BUT: the new Benji/kral Kratos has the bore in hammer WAYYY to undersized. I had to setup the crossfeed grinder to open up the ID of hammer spring bore and make a full new machined spring guide to keep thing inline at full cock. The gun is now silk smooth on cock cycle and picked up over 55 fps on lowest hammer spring adjustment. On full cock the spring gets bigger on OD and hung crap up on firing cycle. so with the extra .050 that I gave it on ID hammer bore and full spring guide everything is free and working perfect on shot cycle.....My back breech bore looked just like this one with gunk, But mine was with STEEL garbage from hammer and OD of spring..

Upvote 0

I've re-assembled the gun after a clean and light polish of the hammer and spring guide. The owner is happy. 60 shots with fps standard deviation of 2.

I just dissembled my brand new wildcat and I see the spring retaining cup part is made of steel rather than aluminium, pity FX did not do the same for the dreamline.

I just dissembled my brand new wildcat and I see the spring retaining cup part is made of steel rather than aluminium, pity FX did not do the same for the dreamline.

Upvote 0

After a pm from xyon, it turns out I have had the same issue. Definitely the rough spring aluminium grater.Photo of my spring adjuster, and flakes on the trigger to compare.

Upvote 0