Due to feds cracking down on everything from oil filters to raw potatoes, I've read quite a bit recently about D-I-Y noise management devices (because I want to avoid that mess). The brief overview is feds apparently decided anything that might be able to be turned into a suppressor by someone with McGyver-like TV talent is enough cause to terrorize U.S. citizens with threats of life-imprisonment and space-alien anal probe research (or something like that). D-I-Y rebels are rebelling (of course) by rolling their own cans (which is not surprising). Air gunners have been needled by feds even though their intent was completely within U.S. law (look up "solvent trap" and "airgun" for the gory details). I had no idea what a "solvent trap" was, or that airgunners were "rolling their own" using hair curlers and Scotch-Brite pads. Again, the intent is to steer clear of and avoid any such situation, political over-reach included.

One modification that came up repeatedly was to stuff legally obtained cans designed for airgun use with Scotch-Brite pads. Doing so does quite down the output significantly, so why don't manufacturers do so themselves?

Suppressors moderate muzzle blast by containing much of it and therefore undergo a large and near-instantaneous pressure increase (the blast), absorption of vibrations (otherwise heard and felt), and discharge of pressure in a rapid but controlled manner (they're not Hollywood "silencers"). As the high pressure rapidly exits there is a pressure decrease in the suppressor and barrel which creates a vacuum and back-draft.

The blast vibrates the sound absorption material found in some suppressors, and the movement is converted to heat (conservation of energy). The more vibration the material absorbs the more sound is converted to heat and the quieter the suppressor output is. This is what makes Scotch-Brite so effective in suppressors, it has a lot of surface area to absorb sound, is stiff enough to dissipate strong vibrations, and is tough enough to last a long time.

The shortcoming is Scotch-Brite material is abrasive, and the powerful blast breaks off small amounts of the material which gets sucked into the barrel. The next shot grinds the abrasive against the relatively soft barrel and removes some of the barrel material, prematurely wearing out the barrel.

To demonstrate I subjected a large Scotch-Brite pad to repeated stress after placing a waffle-weave paper towel underneath so the waffle pattern would contain any debris. Under magnification green Scotch-Brite particles become visible. Although tiny, the particles are just as abrasive, and with the high pressure of a projectile grinding them against the barrel the effect is pronounced, as many airgunners eventually discovered.

The breakdown caught in the back-draft is why suppressor manufacturers use felt or soft foam, if anything at all.

That leads to the next question: Why the screen?

Some manufacturers put a layer of stout stainless-steel mesh between the sound absorption material and the baffles which makes the suppressor "louder" as more high-frequency sound reflects off the screen and exists the muzzle; were the screen not there the sound could go straight into the absorbent and be damped. In part the screen helps keep the material from being sucked into the middle of the suppressor by the brief vacuum created following the shot, and in large-caliber suppressors there may even be an outer layer of screen on the other side of the material to keep the material from being blown apart by the muzzle blast, but there's another reason: to protect the material from "stuff."

Stuff? What kind of stuff?

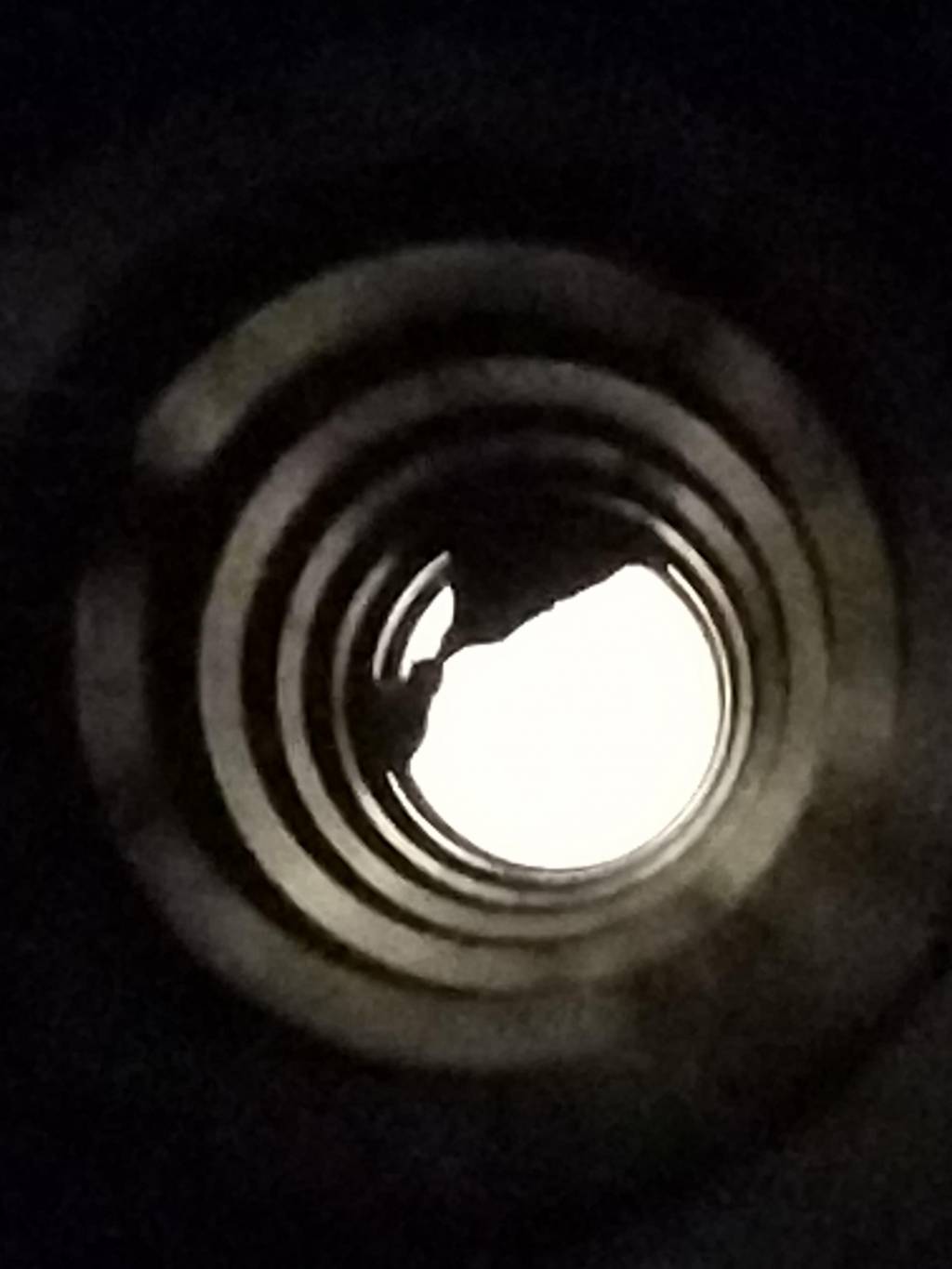

If you wash pellets you're already aware of lead particles left over from the manufacturing process. In some areas there's also rain, and small parts of leaves carried by wind, and bugs, and so forth. Here's something I found looking through the end of a suppressor recently:

Let's take it apart for a closer look:

From what I can tell this is part of a pellet tin wrapper, tightly lodged in a scrubbie.

So there you have it: don't use abrasives in your suppressor--even if they're not green, screens keep the bugs out, and don't buy too many oil filters at once or the government will think you're up to something.

As always your mileage may vary, I'm not your mom so do what you want, and my opinions are based on my experiences and yours may differ greatly.

--WI_Hedgehog

One modification that came up repeatedly was to stuff legally obtained cans designed for airgun use with Scotch-Brite pads. Doing so does quite down the output significantly, so why don't manufacturers do so themselves?

Suppressors moderate muzzle blast by containing much of it and therefore undergo a large and near-instantaneous pressure increase (the blast), absorption of vibrations (otherwise heard and felt), and discharge of pressure in a rapid but controlled manner (they're not Hollywood "silencers"). As the high pressure rapidly exits there is a pressure decrease in the suppressor and barrel which creates a vacuum and back-draft.

The blast vibrates the sound absorption material found in some suppressors, and the movement is converted to heat (conservation of energy). The more vibration the material absorbs the more sound is converted to heat and the quieter the suppressor output is. This is what makes Scotch-Brite so effective in suppressors, it has a lot of surface area to absorb sound, is stiff enough to dissipate strong vibrations, and is tough enough to last a long time.

The shortcoming is Scotch-Brite material is abrasive, and the powerful blast breaks off small amounts of the material which gets sucked into the barrel. The next shot grinds the abrasive against the relatively soft barrel and removes some of the barrel material, prematurely wearing out the barrel.

To demonstrate I subjected a large Scotch-Brite pad to repeated stress after placing a waffle-weave paper towel underneath so the waffle pattern would contain any debris. Under magnification green Scotch-Brite particles become visible. Although tiny, the particles are just as abrasive, and with the high pressure of a projectile grinding them against the barrel the effect is pronounced, as many airgunners eventually discovered.

The breakdown caught in the back-draft is why suppressor manufacturers use felt or soft foam, if anything at all.

That leads to the next question: Why the screen?

Some manufacturers put a layer of stout stainless-steel mesh between the sound absorption material and the baffles which makes the suppressor "louder" as more high-frequency sound reflects off the screen and exists the muzzle; were the screen not there the sound could go straight into the absorbent and be damped. In part the screen helps keep the material from being sucked into the middle of the suppressor by the brief vacuum created following the shot, and in large-caliber suppressors there may even be an outer layer of screen on the other side of the material to keep the material from being blown apart by the muzzle blast, but there's another reason: to protect the material from "stuff."

Stuff? What kind of stuff?

If you wash pellets you're already aware of lead particles left over from the manufacturing process. In some areas there's also rain, and small parts of leaves carried by wind, and bugs, and so forth. Here's something I found looking through the end of a suppressor recently:

Let's take it apart for a closer look:

From what I can tell this is part of a pellet tin wrapper, tightly lodged in a scrubbie.

So there you have it: don't use abrasives in your suppressor--even if they're not green, screens keep the bugs out, and don't buy too many oil filters at once or the government will think you're up to something.

As always your mileage may vary, I'm not your mom so do what you want, and my opinions are based on my experiences and yours may differ greatly.

--WI_Hedgehog

Last edited: