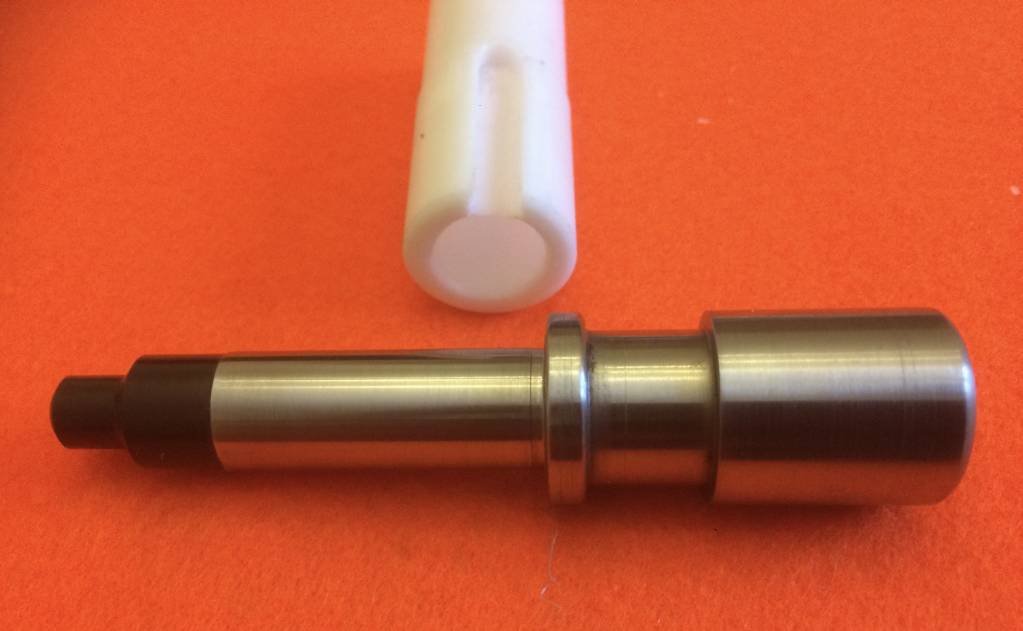

This is a little modification I do to RAW’s and Rapid to support the hammer as it travels towards the valve. It has two functions, firstly because the hammer is not able to wobble about as much, the action noise and subsequent vibrations are massively reduced, making the gun feel smoother. Secondly, the sleeve allows the hammer to strike the valve stem but stops the hammer hitting valve body, avoiding a damaged valve in the event of dry firing without any air in the system.

The sleeve is made from PTFE, it’s a sliding tolerance fit inside the block and over the nose of the hammer. There is a slot to accommodate the cocking dog and a hole to allow for correct positioning and ease of removal. The sleeve is held in place by a M4 grubscrew that is located at the bottom of the stock bolt hole.

Additionally, I have replaced the metal striker on the hammer with one made from delrin, this reduces action noise further. I also reduce the Dia of the nose of the hammer, this reduces weight, allowing the hammer to attain speed more quickly, it move the CofG of the hammer further back so it is more stable as it move within the block and the reduced Dia means greater wall thickness of the support sleeve.

This modification also works exceptionally well with a SSG device both consistency and efficiency are much improved.

Bb

The sleeve is made from PTFE, it’s a sliding tolerance fit inside the block and over the nose of the hammer. There is a slot to accommodate the cocking dog and a hole to allow for correct positioning and ease of removal. The sleeve is held in place by a M4 grubscrew that is located at the bottom of the stock bolt hole.

Additionally, I have replaced the metal striker on the hammer with one made from delrin, this reduces action noise further. I also reduce the Dia of the nose of the hammer, this reduces weight, allowing the hammer to attain speed more quickly, it move the CofG of the hammer further back so it is more stable as it move within the block and the reduced Dia means greater wall thickness of the support sleeve.

This modification also works exceptionally well with a SSG device both consistency and efficiency are much improved.

Bb