Looking back it seems this one last over 1 year then, the Fur Ball gummed up the valve so it need a tear down just for cleaning. As every one of these does this sooner or later and now that you can get them for $75ish I figure they are either repair DIY or throw out ( NO ).

Just some fit & finish pics and saftey removal:

http://www.airgunnation.com/topic/quality-of-the-latest-qb78s/

Then DO be certain the rifle has no pressure, normally on a QB you wont be able to remove the end cap if it does but do be safe.

You need a 2.5mm hex wrench and both a straight and Phillips screw driver as well as a section of flat bar stock or a screw long screw driver that will reach the front of the valve. If replacing orings try Ace hardware or better any paintball store.

Then, remove safety using bic pen or such, remove stock.

The order here can be pretty much what ever.

Remove the rear trigger screw and both end cap's then the bolt handle by using the 2.5mm to loosen the retaining screw in center of bolt, handle pulls right out.

Barrel is held in with ( unfortunately ) only 1 3.5mm screw

With the barrel removed, it just pulls straight out, might be good to slide the barrel band off the air tube first. you can now access the forward breech screw - Phillips- which needs to be removed

Remove the small phillips valve retention screw and the stock bolt/stud which anchors the metal disc behind the valve - make sure the get that metal spacer part behind the valve in the right direction, it is offset to one side.

Now you've lieky dump the receiver parts already if going A,B,C, here with me but if not do remove breech then note the two cocking pins one has a round head the other square, the square one goes towards the rear of the rifle.

This newer QB actually had somewhat of a formed seal I believe, I looked at it closely and it really looks more shaped than squished?

The striker ( I guess most think they are hammers these days ) was MUCH smoother than QB's - or Gauntlet's- past but a high polish would be good.

While the transfer port in the barrel is TINY - just under 2.5mm- the valve port is plenty large for a .22

The valve that came out had the dreaded white spacer which I replaced with an oring

The reason I dont care for that spacer is the valve simply dropped out. Using an oring you would need that special tool/screw driver to reach into the front of the valve and unscrew it 1/2 to 1 turn allowing the oring to decompress and slide the valve out.

When I put it back together I did use an oring, slide valve in, aligned holes using smallest allen wrench, installed small valve retention screw then tightened the valve body halves using the section of bar stock. Just snug on the oring NOT tight!

And the reason QB's all fail ( and are an outstanding value nonetheless ) the Fur Ball of death

I'm not at all sure what this "filter" is made of but it feels just like dryer lint and really should be removed when new but sometimes they do last well beyond warranty, somehow.

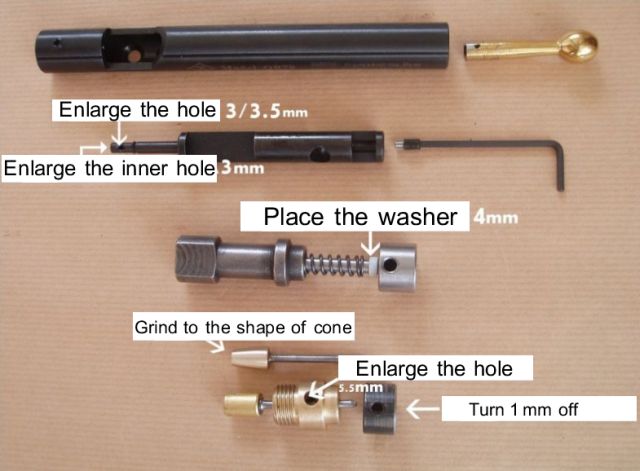

As I had an extra front valve half that was slightly opened up - # 1 power mod for a QB - I installed that one , modded on left

The factory- on this one- valve stem left and an older style on the right - I installed the one on the right-

Only takes 10 minutes. Any new folks wanting to learn just what's inside an airgun - pre-charged airgun's are pretty much the same- might consider a QB just for that. Recently on sale for $69.00 shipped if you shop around, good trigger, easy to bulk fill - just change the end cap- can be modded for good power. Fun little rifles you can give to your nephews or nieces after some fun Winter tweaking.

If your a QB fan do add any tip's trick's or mod's you use.

John

Just some fit & finish pics and saftey removal:

http://www.airgunnation.com/topic/quality-of-the-latest-qb78s/

Then DO be certain the rifle has no pressure, normally on a QB you wont be able to remove the end cap if it does but do be safe.

You need a 2.5mm hex wrench and both a straight and Phillips screw driver as well as a section of flat bar stock or a screw long screw driver that will reach the front of the valve. If replacing orings try Ace hardware or better any paintball store.

Then, remove safety using bic pen or such, remove stock.

The order here can be pretty much what ever.

Remove the rear trigger screw and both end cap's then the bolt handle by using the 2.5mm to loosen the retaining screw in center of bolt, handle pulls right out.

Barrel is held in with ( unfortunately ) only 1 3.5mm screw

With the barrel removed, it just pulls straight out, might be good to slide the barrel band off the air tube first. you can now access the forward breech screw - Phillips- which needs to be removed

Remove the small phillips valve retention screw and the stock bolt/stud which anchors the metal disc behind the valve - make sure the get that metal spacer part behind the valve in the right direction, it is offset to one side.

Now you've lieky dump the receiver parts already if going A,B,C, here with me but if not do remove breech then note the two cocking pins one has a round head the other square, the square one goes towards the rear of the rifle.

This newer QB actually had somewhat of a formed seal I believe, I looked at it closely and it really looks more shaped than squished?

The striker ( I guess most think they are hammers these days ) was MUCH smoother than QB's - or Gauntlet's- past but a high polish would be good.

While the transfer port in the barrel is TINY - just under 2.5mm- the valve port is plenty large for a .22

The valve that came out had the dreaded white spacer which I replaced with an oring

The reason I dont care for that spacer is the valve simply dropped out. Using an oring you would need that special tool/screw driver to reach into the front of the valve and unscrew it 1/2 to 1 turn allowing the oring to decompress and slide the valve out.

When I put it back together I did use an oring, slide valve in, aligned holes using smallest allen wrench, installed small valve retention screw then tightened the valve body halves using the section of bar stock. Just snug on the oring NOT tight!

And the reason QB's all fail ( and are an outstanding value nonetheless ) the Fur Ball of death

I'm not at all sure what this "filter" is made of but it feels just like dryer lint and really should be removed when new but sometimes they do last well beyond warranty, somehow.

As I had an extra front valve half that was slightly opened up - # 1 power mod for a QB - I installed that one , modded on left

The factory- on this one- valve stem left and an older style on the right - I installed the one on the right-

Only takes 10 minutes. Any new folks wanting to learn just what's inside an airgun - pre-charged airgun's are pretty much the same- might consider a QB just for that. Recently on sale for $69.00 shipped if you shop around, good trigger, easy to bulk fill - just change the end cap- can be modded for good power. Fun little rifles you can give to your nephews or nieces after some fun Winter tweaking.

If your a QB fan do add any tip's trick's or mod's you use.

John