I posted a question for help yesterday on a thread I had started earlier, but it seems to have dead ended, and I couldn't get an answer or help to my question.

The question will mostly be directed to Hatsan air rifle owners with experience in the removable air cylinder.

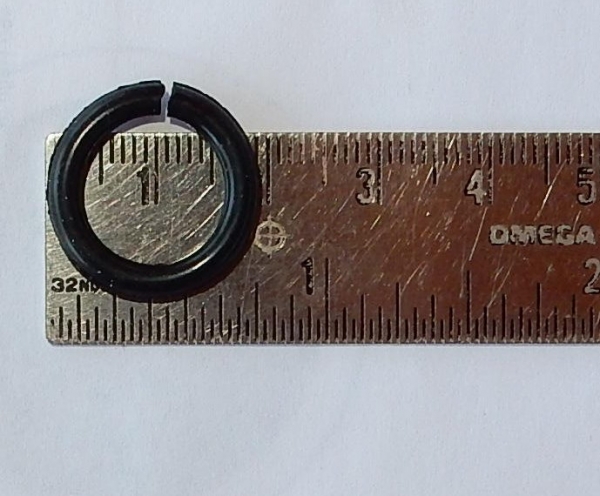

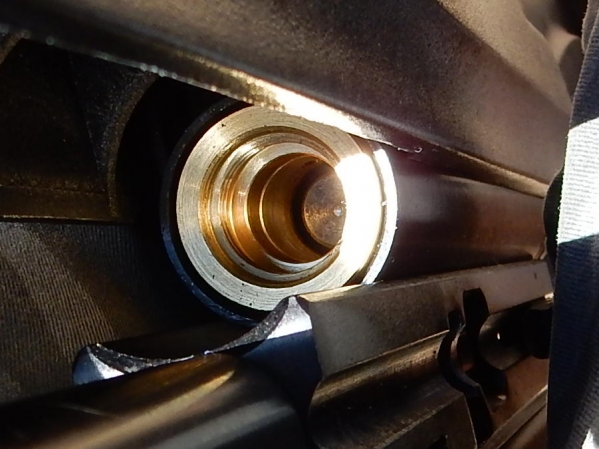

I'm a 3 day owner to my first PCP rifle. Yesterday on my deck I found a broken oily O ring in the area where I have been pumping up my gun, and also the same spot where I first unscrewed the air cylinder from the gun. I first thought that the O ring may have came from the end of the air cylinder where it screws in, but I don't think so now. The size isn't right My rifle came with a bag of O ring spares, but none are the same size as this one. My pump also came with an assortment of O ring spares, and there is one that looks to be the same size. I can't imagine this O ring coming from the pump. Its never been disassembled. Is it possible there may be another O ring inside the gun where the air cylinder is screwed in.

I'm attaching photos of the broken O ring with a ruler for size comparison, the end of the air cylinder and a view of where the cylinder screws in.

I would very much appreciate some help or opinions if they can see anything that doesn't look right. I don't have any problem pumping my gun up, and once I do, it seems to hold a charge. The gun does seem to drop down in pressure faster than I expected when it is shot.

Lamar

The question will mostly be directed to Hatsan air rifle owners with experience in the removable air cylinder.

I'm a 3 day owner to my first PCP rifle. Yesterday on my deck I found a broken oily O ring in the area where I have been pumping up my gun, and also the same spot where I first unscrewed the air cylinder from the gun. I first thought that the O ring may have came from the end of the air cylinder where it screws in, but I don't think so now. The size isn't right My rifle came with a bag of O ring spares, but none are the same size as this one. My pump also came with an assortment of O ring spares, and there is one that looks to be the same size. I can't imagine this O ring coming from the pump. Its never been disassembled. Is it possible there may be another O ring inside the gun where the air cylinder is screwed in.

I'm attaching photos of the broken O ring with a ruler for size comparison, the end of the air cylinder and a view of where the cylinder screws in.

I would very much appreciate some help or opinions if they can see anything that doesn't look right. I don't have any problem pumping my gun up, and once I do, it seems to hold a charge. The gun does seem to drop down in pressure faster than I expected when it is shot.

Lamar