A few weeks back there were several posts on the "on sale" Coltri MCH6 compressors from Nuvair. After a bit of contemplation, I decided to order one. The unit arrived at my local Fedex freight yard with a few days after ordering. I decided to get the unit at the freight yard with my pickup truck to avoid the additional delivery charge. The compressor could have fit in the trunk of my Camry if it was unpackaged at the yard. Nuvair does a great job palletizing the shipment box to avoid shipping damage. The folks at Nuvair also test the compressor before shipping as I was told. My compressor arrived with 1 hour and 27 minutes on the hour meter.

My first impression of the compressor was that it was cosmetically perfect. All oil reservoirs were filled. This is not the case with most products that require lubrication. Nuvair also provides additional documentation on the startup/shutdown procedures and maintenance. One thing I found interesting is that they recommend the "break-in" oil be changed at the two (2) hour point. I was seeing five (5) hours in other literature.

The MCH6 has several improvements coming. In December, they announced their crankshafts will be coming with hardened forged rings. My guess is my unit didn't come with these. They announced a cosmetic change to their cylinder heads in the future early this year. They will be coated with an amber clear varnish in production.

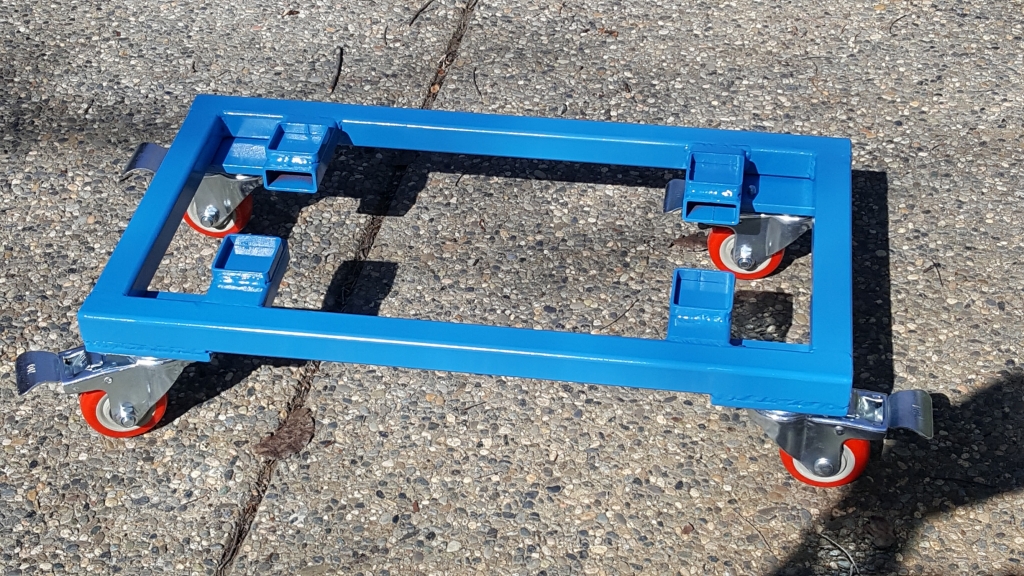

I made a few enhancements to my setup on the cheap. The first thing I did was built a rolling base for it. The unit weighs 80 lbs. according to the documentation which is not all that portable.

Here's the compressor of the base:

I plan to store the compressor in a utility room off of my garage that can get a bit dusty so I bought a cover for it:

I ran the compressor for a short top off session earlier in the week and it is fast. Much faster than my Yong Heng and a lot less hassle to setup.

My first impression of the compressor was that it was cosmetically perfect. All oil reservoirs were filled. This is not the case with most products that require lubrication. Nuvair also provides additional documentation on the startup/shutdown procedures and maintenance. One thing I found interesting is that they recommend the "break-in" oil be changed at the two (2) hour point. I was seeing five (5) hours in other literature.

The MCH6 has several improvements coming. In December, they announced their crankshafts will be coming with hardened forged rings. My guess is my unit didn't come with these. They announced a cosmetic change to their cylinder heads in the future early this year. They will be coated with an amber clear varnish in production.

I made a few enhancements to my setup on the cheap. The first thing I did was built a rolling base for it. The unit weighs 80 lbs. according to the documentation which is not all that portable.

Here's the compressor of the base:

I plan to store the compressor in a utility room off of my garage that can get a bit dusty so I bought a cover for it:

I ran the compressor for a short top off session earlier in the week and it is fast. Much faster than my Yong Heng and a lot less hassle to setup.