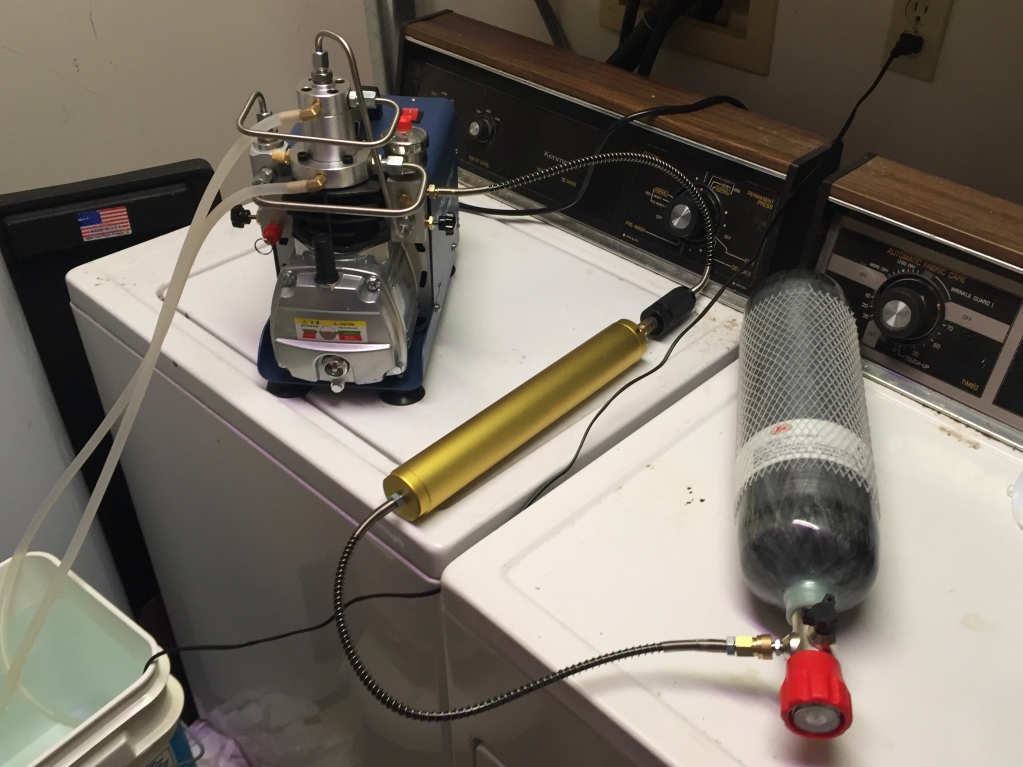

This is my new compressor and tank setup.

The Yong Heng Compressor

It’s hefty and looks well built. The user manual is not the greatest, but I figured everything out before I used it. I’d probably not recommend this for someone who’s not mechanically inclined. I’ve seen some how to use videos by guys not using it right.

I shopped around and found a seller on eBay in the US who has the 110VAC adjustable pressure auto shut off model for the price of the base model. It arrived in 4 days in perfect condition. Grainger was the only local place I could find the correct oil. I bought a gallon of Mobil 427 ISO 100 anti-wear compressor oil. The user manual says ISO 46, but then recommends Mobil 827 ISO 100. Go figure. I went with the 100. After putting a total of 1 hour of use on the compressor, the oil had a clear medium gray appearance and I decided to change the oil at that point. Likely the gray is metal sediment from wearing in of the compressor parts. The compressor runs beautifully and fills fast. $268 for the 110 VAC adjustable pressure compressor and $41 for the gallon of oil.

Water and Oil Separator

The small separator that comes with the compressor will be very saturated with water and some oil on a 30 minute run. You absolutely need an extra filter. I added a hefty 18” Tuxking separator after it. The small one removes most of the condensation and the large one takes care of the rest. I modified it though. I inserted a 6cm piece of the fiber filter at the inlet end filled the rest packed tight with blue indicating molecular sieve beads and then a 2cm fiber filter piece at the outlet end.

After a 30 minute run with no periodic opening of the drain valves, the compressor’s small separator is saturated. Then inspecting the outlet end of the big separator, it is completely dry and no oil residue. At the inlet end there is some moisture and evidence of a little oil residue in the fiber filter, but most of that piece is dry. I ordered a small 5” fiber separator to add before the big one. The idea being to contain all the liquid condensate in that, which will mean that the molecular beads will be depleted less. One other mod I’m making is to put a check valve on the tank connect line so I can bleed the compressor to no load before shutting off. Just something that’ll take a tad more stress off the compressor.

Releasing some air from the filled tank, I don’t smell anything other than some new tank smell. Nothing oily or otherwise. I feel very confident that this big modified separator is doing an excellent job at keeping the tank dry and oil free. $89 for the separator and $30 for 2 lbs of molecular sieve beads.

The Tank

After browsing lots of SCBA and SCUBA tanks, I decided to buy an iorman 3L 4500 PSI carbon fiber SCUBA tank with the valve and hose included. It’s an excellent well built looking tank and valve setup! It looks very made. I bought a very nice padded shoulder bag made for the tank. $299 for the tank setup.

Summing Up

I’m very happy with this setup for $729 including the oil and sieve beads. When the 3L tank got down below 3000 PSI, it took 7 minutes to charge it up to 4300 PSI. When charging my PCP rifle, the tank valve gives you good fill rate control. That 3L tank will give me plenty of refills for a day out shooting. I estimate it’ll fill my Gauntlet 25 around 14 times, which takes about 2 seconds.

I was looking at the Nomad compressor at about the same price as this setup and I’d much rather have this setup! The on the go mobility is far better. I can fill this tank from low in 7 minutes and take it with me anywhere and get around 14 or so quick refills instead of having to go connect up a noisy compressor, be tethered to a power source, and then wait for the rifle to fill.

The Yong Heng Compressor

It’s hefty and looks well built. The user manual is not the greatest, but I figured everything out before I used it. I’d probably not recommend this for someone who’s not mechanically inclined. I’ve seen some how to use videos by guys not using it right.

I shopped around and found a seller on eBay in the US who has the 110VAC adjustable pressure auto shut off model for the price of the base model. It arrived in 4 days in perfect condition. Grainger was the only local place I could find the correct oil. I bought a gallon of Mobil 427 ISO 100 anti-wear compressor oil. The user manual says ISO 46, but then recommends Mobil 827 ISO 100. Go figure. I went with the 100. After putting a total of 1 hour of use on the compressor, the oil had a clear medium gray appearance and I decided to change the oil at that point. Likely the gray is metal sediment from wearing in of the compressor parts. The compressor runs beautifully and fills fast. $268 for the 110 VAC adjustable pressure compressor and $41 for the gallon of oil.

Water and Oil Separator

The small separator that comes with the compressor will be very saturated with water and some oil on a 30 minute run. You absolutely need an extra filter. I added a hefty 18” Tuxking separator after it. The small one removes most of the condensation and the large one takes care of the rest. I modified it though. I inserted a 6cm piece of the fiber filter at the inlet end filled the rest packed tight with blue indicating molecular sieve beads and then a 2cm fiber filter piece at the outlet end.

After a 30 minute run with no periodic opening of the drain valves, the compressor’s small separator is saturated. Then inspecting the outlet end of the big separator, it is completely dry and no oil residue. At the inlet end there is some moisture and evidence of a little oil residue in the fiber filter, but most of that piece is dry. I ordered a small 5” fiber separator to add before the big one. The idea being to contain all the liquid condensate in that, which will mean that the molecular beads will be depleted less. One other mod I’m making is to put a check valve on the tank connect line so I can bleed the compressor to no load before shutting off. Just something that’ll take a tad more stress off the compressor.

Releasing some air from the filled tank, I don’t smell anything other than some new tank smell. Nothing oily or otherwise. I feel very confident that this big modified separator is doing an excellent job at keeping the tank dry and oil free. $89 for the separator and $30 for 2 lbs of molecular sieve beads.

The Tank

After browsing lots of SCBA and SCUBA tanks, I decided to buy an iorman 3L 4500 PSI carbon fiber SCUBA tank with the valve and hose included. It’s an excellent well built looking tank and valve setup! It looks very made. I bought a very nice padded shoulder bag made for the tank. $299 for the tank setup.

Summing Up

I’m very happy with this setup for $729 including the oil and sieve beads. When the 3L tank got down below 3000 PSI, it took 7 minutes to charge it up to 4300 PSI. When charging my PCP rifle, the tank valve gives you good fill rate control. That 3L tank will give me plenty of refills for a day out shooting. I estimate it’ll fill my Gauntlet 25 around 14 times, which takes about 2 seconds.

I was looking at the Nomad compressor at about the same price as this setup and I’d much rather have this setup! The on the go mobility is far better. I can fill this tank from low in 7 minutes and take it with me anywhere and get around 14 or so quick refills instead of having to go connect up a noisy compressor, be tethered to a power source, and then wait for the rifle to fill.