I have two FX Impact MKIIs, a .25 and a .30 which are great rifles but I’ve never been satisfied with their triggers. I’ve watched Ernest”s videos and they were quite helpful to disassemble, assemble and adjust my triggers but (no offense) were lacking in achieving a better feeling trigger. In stock form my .25 had a 1#-6oz trigger pull and the .30 had a 1#-3oz trigger, which is certainly acceptable for a hunting trigger but since mine are mostly used to punch holes in paper I wanted a smoother and lighter trigger pull. First of all I will disclose that I am not a gunsmith nor do I play one on TV but I have always done my own wrenching and tuning on my PB firearms. I am not advocating that anyone do what I have done to their trigger as it may void your warranty and may render your rifle to be unsafe. I am merely documenting my journey to a lighter and much smoother trigger.

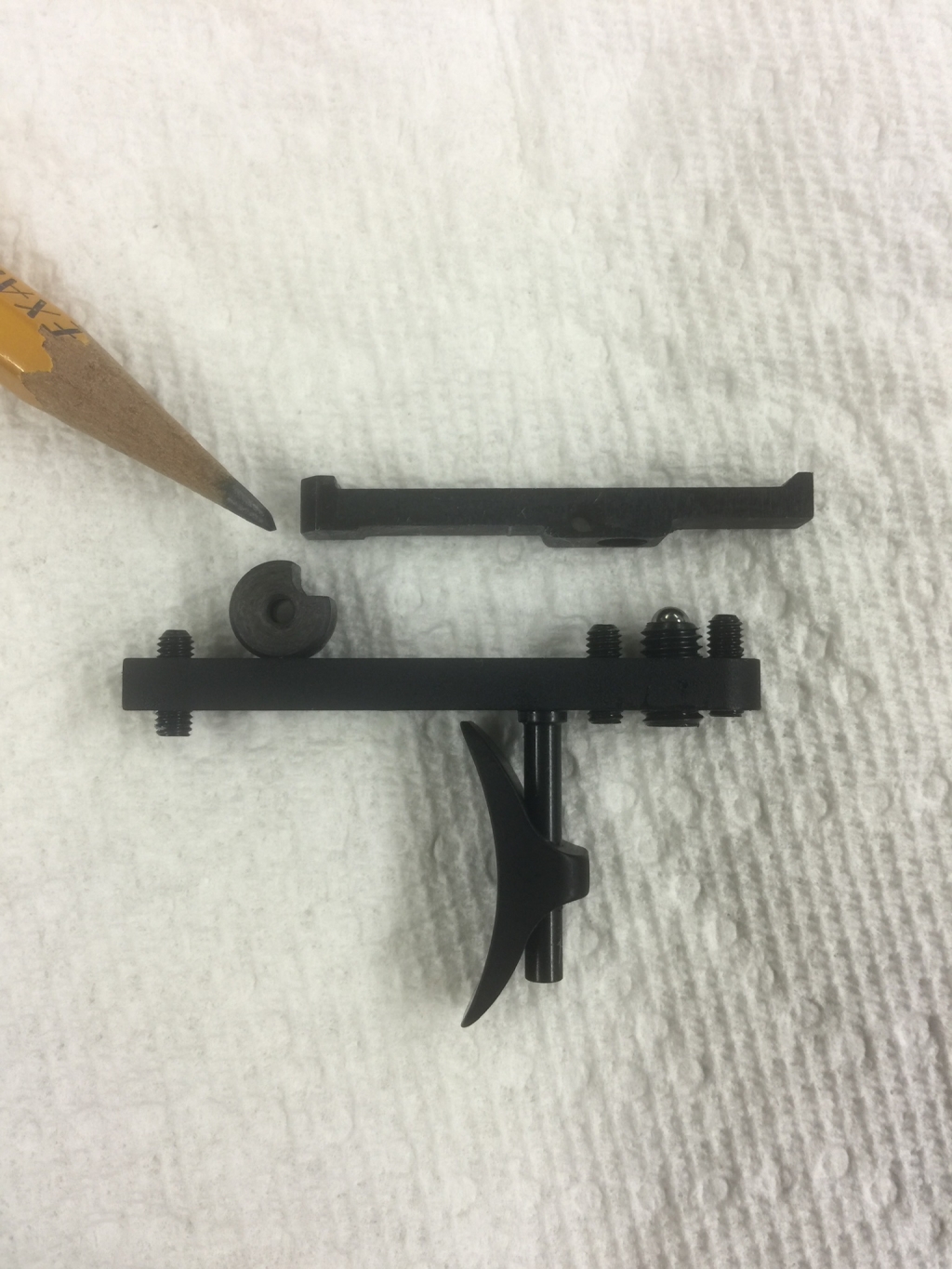

I followed Ernest’s videos to understand the relationship of the trigger bar and sear interface which is where I wanted to polish to improve the feel and smoothness of the trigger pull. The pencil is pointing to the interface of the trigger bar and sear.

I proceeded to LIGHTLY buff and polish these interface surfaces WITHOUT altering their shapes or edge profiles. I used a Dremel, cotton buff and Flitz metal polish. I ran the Dremel on the slowest speed so as not to overheat and anneal the surfaces of the metal.

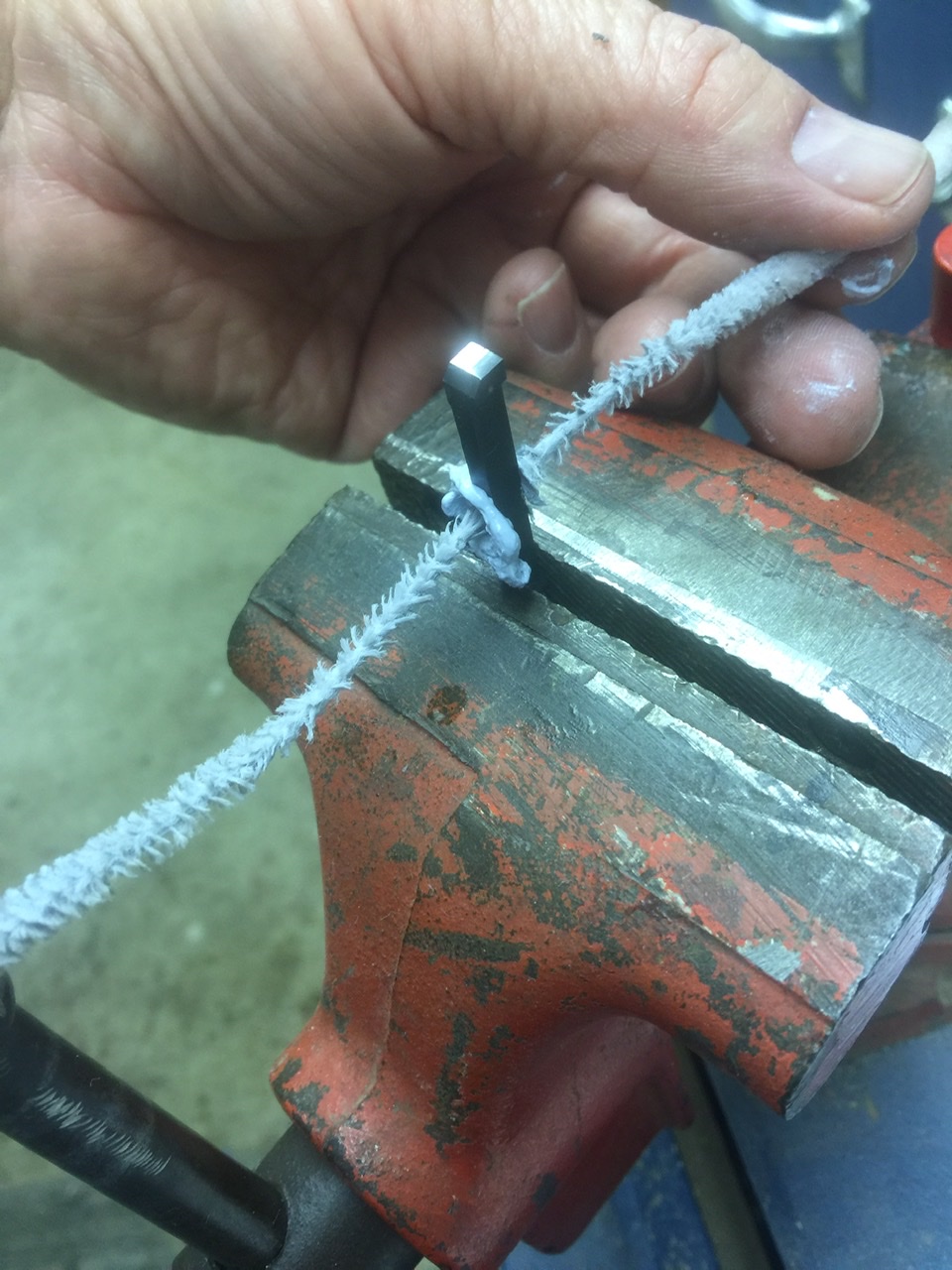

Next I polished the pins and holes that these two parts pivot on. I used the Dremel to polish the pins and coated a pipe cleaner with Flitz and “flossed” the holes while holding the two parts in a vise.

After the parts were polished I washed them in kerosene, brake cleaner and finally dried with compressed air and set aside.

I followed Ernest’s videos to understand the relationship of the trigger bar and sear interface which is where I wanted to polish to improve the feel and smoothness of the trigger pull. The pencil is pointing to the interface of the trigger bar and sear.

I proceeded to LIGHTLY buff and polish these interface surfaces WITHOUT altering their shapes or edge profiles. I used a Dremel, cotton buff and Flitz metal polish. I ran the Dremel on the slowest speed so as not to overheat and anneal the surfaces of the metal.

Next I polished the pins and holes that these two parts pivot on. I used the Dremel to polish the pins and coated a pipe cleaner with Flitz and “flossed” the holes while holding the two parts in a vise.

After the parts were polished I washed them in kerosene, brake cleaner and finally dried with compressed air and set aside.