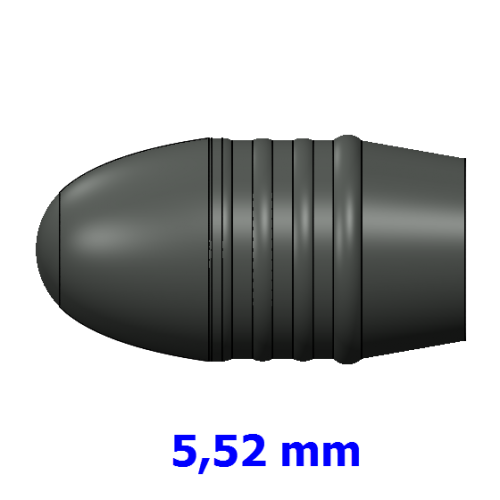

Hi guys just wondered if anyone on the forum has tested the .22 MP 5.52 molds and what the accuracy is like. So if anyone has indeed purchased these could you let me know what the ballistic characteristics is like along with how accurate are they. Here is an image of the mold

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MP Molds Advice

- Thread starter MddogHutty

- Start date

I have tried then in 8 guns and they worked great in half of them , Mine shoot best in the unchoked barrel going 900 fps , but one of my guns shoots them fine in 25 caliber at 700s fps , they are heavy so you need energy to push them well , what barrel do you have or gun ? LOU

Upvote 0

I have this as well, they do well at 50 and 100m from a lw unchoked poly. Like JW said they are heavy 35.5gr or so, so youll need 50+ fpe to push them. Over 60 is probably preferable.

Upvote 0

What I'm after is been able to make my own 22 rifle slugs like the 21g Nielson slugs they fire well and accurate. If I could get a mould like the ones they make would be ideal.

Upvote 0

G

Guest

Guest

Remember guys, there are 2 types of mp moulds. one in 5.52 and other in .223-.224. the larger ones are for Huben only. Dont mistake the huben ones for 5.52mm ones.

Mddoghutty, Nielsen slugs are made with swaging die. the moulds wont create .217 NSA style slugs

Mddoghutty, Nielsen slugs are made with swaging die. the moulds wont create .217 NSA style slugs

Upvote 0

Hi there I am a new user of mp molds for 5.52mm I have some issues by molding. Why the some slugs have marks on them maybe something wrong with my molding way can you please suggest

Upvote 0

Probably this is first drop of lead that hardens before other lead comes in. Usually not hot mould enough or to cold lead. Smaller the harder to get perfect bullet, specialy with those rings.

Once you got temperature you will cast perfect slugs!

Once you got temperature you will cast perfect slugs!

Upvote 0

I am using pure lead and the lead was also too hot the mold was hot enough maybe hands were shaking while pouring the lead but the rings are also not perfect

Upvote 0

Probably this is first drop of lead that hardens before other lead comes in. Usually not hot mould enough or to cold lead. Smaller the harder to get perfect bullet, specialy with those rings.

Once you got temperature you will cast perfect slugs!

Are you using pure lead? Or adding something for hardness

Upvote 0

I use pure lead, so slugs are soft. But adding some tin you will be able to fill rings and details better!

Upvote 0

I'm a caster. Both pellets and slugs for .25 cal. My lead temp is 800°F and I run my brass NOE molds about 340+ °F. How are you filling your mold when you pour? Are you using a bottom pour casting pot or by ladel? You must make sure that the lead goes into the sprue hole as close to center as possible. Or you will get uneven pours and the unfilled circles you are seeing. I haven't used an mp mold. But I know it is aluminum. They loose heat quickly so your casting tempo needs to be quick and steady to keep the heat in the mold. Temperature is the major factor. Try tuning up the temps by 20-25°F until you get good fill out and the circle defects to away. Oh and I also only use pure.lead with no tin.

Upvote 0

I use ladel, I don't have pot. I just use stove to melt the lead and heat up my mold I know this is not the Wright thing I am doing but I don't have pot. I will try to increase my mold temperature this time

Upvote 0

I found hard making perfect bullets even with casting pot with any other way i dont even imagen casting bullets like this.

Upvote 0

I use ladel, I don't have pot. I just use stove to melt the lead and heat up my mold I know this is not the Wright thing I am doing but I don't have pot. I will try to increase my mold temperature this time

I hope your stove is outside. Unless you like feeling the effects of lead poisoning

Upvote 0

Yes you are right it was my first time to do it and the room smells like charcoal. I am looking forward to buy a pot

Upvote 0

Yes you are right it was my first time to do it and the room smells like charcoal. I am looking forward to buy a pot

Upvote 0

Ladle pouring is ok. You need to have a thermometer in the lead son that you know what temp it is at. I started off this was myself. now when you say ladle do you mean an open style or the one with the little spout on the side of it? The one with a spout on the side will work better as it gives the mold a small amount of head pressure to get the cavity to fill out.

just keep trying. You'll get it then it will be an ahhha moment. Keeping good rhythm and don't check for defects in between each mold drop. Just do a bunch then weed out the rough ones at the end of the session.

just keep trying. You'll get it then it will be an ahhha moment. Keeping good rhythm and don't check for defects in between each mold drop. Just do a bunch then weed out the rough ones at the end of the session.

Upvote 0

Ladle pouring is ok. You need to have a thermometer in the lead son that you know what temp it is at. I started off this was myself. now when you say ladle do you mean an open style or the one with the little spout on the side of it? The one with a spout on the side will work better as it gives the mold a small amount of head pressure to get the cavity to fill out.

just keep trying. You'll get it then it will be an ahhha moment. Keeping good rhythm and don't check for defects in between each mold drop. Just do a bunch then weed out the rough ones at the end of the session.

I am very thankful for you suggestions really appreciate it. It gave me a hope that I could get the goal. I mean the open style pouring with a mug I have with a little bit bigger spout on the side to pour, I will try to get a small pouring ladle which you are suggesting till I get a bottom pouring pot. Can you please give me some more informations about the mixture or the lead, I mean tin how much to add with the lead. And also please tell me the soldering lead which have 60% tin is good to mix with lead because in my country I don't know how to find tin. Looking forward to get some more information about molding because I am new in this field it's my first time to mold.

Regards

Baloch

Upvote 0