Ultimately, my advise on this is going to be... Pay your retailer to do it for you! If they screw it up, they get you a new one. If you screw it up, you eat it!

This is the 2nd hardest install I've ever taken on due to the shape of the rifle at the tongue. (This is me telling you not to do this to your rifle and to not put it on me if you do and something goes wrong.)

Is it doable? Yup.

Is it strong enough? Yup.

DIY? Yup, just take your time. "Measure twice, cut once?" No... Measure 3-4 times.

The Daystate Red wolf stock reminds me of an Italian spots car. Ferrari comes to mind, probably because of all the red color! But, it goes beyond the color. When you really take a good look at the curves on this stock, you see the inspiration that DS had to put something beautiful and elegant out to the market. I think they succeeded. The lines and contours on this stock are like no other I've ever seen coming straight from a factory.

This beauty comes with a price though. Ever tried putting a roof rack on a Murciélago? It's not easy. It's not impossible but, it's not easy. The car just wasn't designed for utility style jobs.

Personally, I can't stand shooting off a front sandbag. It doesn't hold the rifle securely and all the rifle wants to do is tip over whenever you take your hands off it. One of the very first things I do, before I even get a rifle in my hands, is buy a picatinny rail for it. I already know I'll be using an Atlas bipod (more recently, Accu-Tac has caught my attention) so, I already know I'm going to have to slap a rail on. Being a hobbyist woodworker, I feel confident that I can take on a project like this myself.

2 reasons I won't use a sling stud Harris style bipod. 1) I don't like them as much as Atlas/Accu-tac. 2) The thickness of the tongue on bottle guns is thin to SUPER THIN, which forces you to install the stud farther back where the bottle curves and stock thickens. You know what else is in that area? The fill port! If you don't want your fill port covered by your bipod base, you have to move the stud forward and right into the thinnest area of the stock. Sure, a T-nut is an option. But, in order to install it, you need to make a thin area even thinner.

Personally, I like my bipod as faaar forward as I can get it. So, I consider my options, break out the rulers and start figuring for location vs. strength vs. aesthetics.

Pictured here are the Atlas BT13, a keyhole style rail I got of eBay, and an Atlas BT34.

My goal is to have picatinny slots as far forward as I possibly can while retaining as much strength as I can. So, screw hole positioning is critical.

Out come the rulers...

I've got 3 inches until the curve starts and the stock gets thicker.

Remember that sports car analogy? Well, here's where things get interesting. ***The front of the stock, the thinnest part, has also been shaped with a concave curve into it.*** Not only that, but it's convex as well (right to left). Two opposing curves at two opposite angles = challenge!

Off comes the stock and out comes the blue painters tape! It's time to start making landmarks. First I mark the forward edge of the bottle curve. This is where the stock quickly gets thick. and I can get a good anchor point.

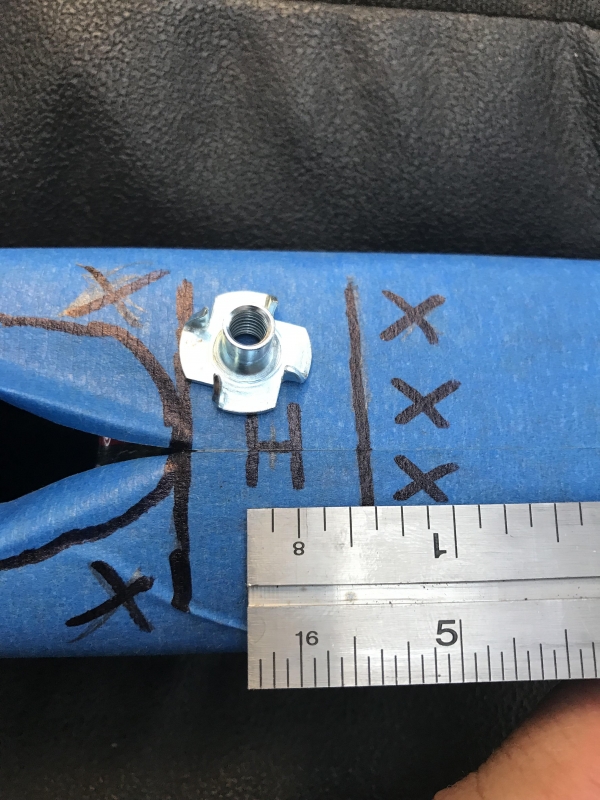

OK, lots going on in this next pic....

I'm concerning myself with locating the rear screw only. I'm fighting the front edge of the bottle curve and the rear edge where the fill port scalloping is (that's the oval shape drawn on the tape). Overall, I only have 1 inch of space to work in. But, I'm also fighting the diameter of the T-nut which I plan to use. This one has a slightly smaller diameter than the ones supplied by Atlas. I picked it up at a hardware store.

That little "I" or "H" in the center signifies the max point at which I can drill rearward and forward as well as a "mock" centerline. So, that 1 inch I had is really only 1/4". I guess that makes it easy! Due to limitation of space, the rear goes here. End of story!

The ebay rail is a fail. Bitter-sweet, really. It would have been nice to have all those slots but it's got a flat bottom and would have been a lot of work.

The short Atlas will work just fine. Just sucks that it's so far back and so short.

Looks like it's going to be the longer Atlas rail but, forward of backwards?

Ultimately, I mounted it like the first pic. It gives me less slots at the very tip of the tongue. I did this purposely to stop myself from mounting the bipod so far forward that it would put extra strain on the wood.

With the rail located and marked, it's time to start modifying the picatinny rail. Remember those two opposite and opposing curves I talked about earlier?

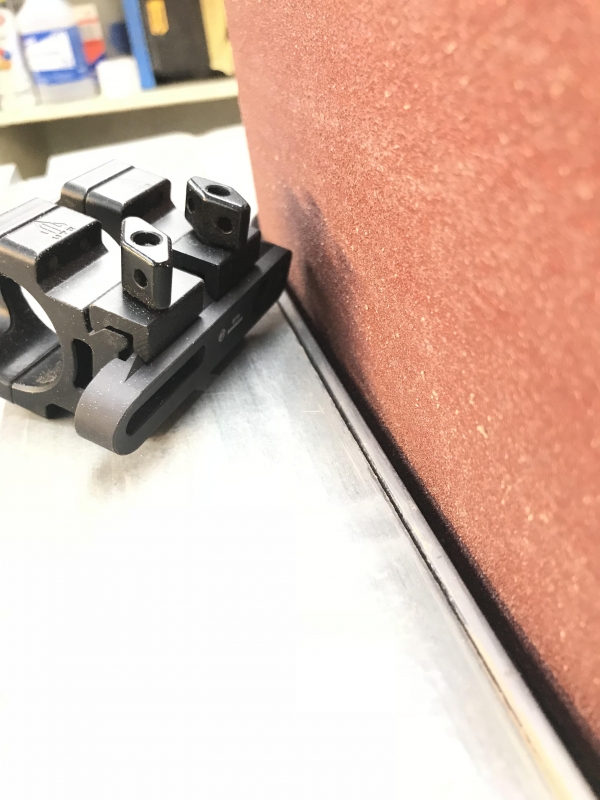

I mounted the rail to some scope mounts to give myself something to hold onto and to help keep the rail level. Then, headed off to the table top sander to shape the bottom of the aluminum rail.

I took it further than this but, it shows pretty well what I was after.

I re-taped, found the center line, and finalized my markings.

Then, sand, test, sand, test, sand, test, Ouch! HOT! Cool it off. sand, test, sand, test...

Once I was happy with the rail, I started into the drilling process.

I won't go into detail on this as I've covered it a few times in the past.

Thread link Video link

This is a jig I made in order to support the laminated wood from splitting. I used scrap wood to cut out the shape of the tongue, then cut it down the middle to remove some material. Screwed it to another block of wood to allow the sides to swivel and clamped it in place. It's a lot of work to go through but, it supports the whole front end of the stock from splitting.

You might wonder why I didn't just use the clamp alone. Well, along with those opposite and opposing curves, the tongue also has a taper to it! That makes it nearly impossible to properly clamp using a clamp alone. There's a lot of angles going on in this little section of the stock! Just finding the true center line was an exercise!

When I put the wood screw in, I applied a little wax to it. This was to help it cut threads into the wood a little easier. I also treated it like a tap where I slowly worked it in a little and then backed it out a little, then slowly in and back out...

I lost a little finish but, I'm not worried about it. It's on the inside, and I'll never see it.

This is really meant to show how much of the wood screw needed to be cut off.

Final install of the rail. Wood screw in the front, machine screw in the back.

That is one DEEP hole for the T-nut! It had to be in order to clear the bottle.

Take a moment to think about the forces being applied by the bipod. Overall, it's downward force from the weight of the rifle. But, with the legs at a 45º angle, there's a twisting force involved as well. The back anchor bolt could be experiencing a "pulling" force and the front could be experiencing a "pushing" force. Because of this, I think of the rear bolt as the work horse, holding all the weight, and I think of the front screw as a guide, just keeping things in line.

I don't beat the heck out of my rifles or go running around playing commando with them. Primarily it will sit on a bench and shoot just like whats pictured above. So, there is plenty of support here for what I do.

Thanks!

Hope you enjoyed my story!

Tom

This is the 2nd hardest install I've ever taken on due to the shape of the rifle at the tongue. (This is me telling you not to do this to your rifle and to not put it on me if you do and something goes wrong.)

Is it doable? Yup.

Is it strong enough? Yup.

DIY? Yup, just take your time. "Measure twice, cut once?" No... Measure 3-4 times.

The Daystate Red wolf stock reminds me of an Italian spots car. Ferrari comes to mind, probably because of all the red color! But, it goes beyond the color. When you really take a good look at the curves on this stock, you see the inspiration that DS had to put something beautiful and elegant out to the market. I think they succeeded. The lines and contours on this stock are like no other I've ever seen coming straight from a factory.

This beauty comes with a price though. Ever tried putting a roof rack on a Murciélago? It's not easy. It's not impossible but, it's not easy. The car just wasn't designed for utility style jobs.

Personally, I can't stand shooting off a front sandbag. It doesn't hold the rifle securely and all the rifle wants to do is tip over whenever you take your hands off it. One of the very first things I do, before I even get a rifle in my hands, is buy a picatinny rail for it. I already know I'll be using an Atlas bipod (more recently, Accu-Tac has caught my attention) so, I already know I'm going to have to slap a rail on. Being a hobbyist woodworker, I feel confident that I can take on a project like this myself.

2 reasons I won't use a sling stud Harris style bipod. 1) I don't like them as much as Atlas/Accu-tac. 2) The thickness of the tongue on bottle guns is thin to SUPER THIN, which forces you to install the stud farther back where the bottle curves and stock thickens. You know what else is in that area? The fill port! If you don't want your fill port covered by your bipod base, you have to move the stud forward and right into the thinnest area of the stock. Sure, a T-nut is an option. But, in order to install it, you need to make a thin area even thinner.

Personally, I like my bipod as faaar forward as I can get it. So, I consider my options, break out the rulers and start figuring for location vs. strength vs. aesthetics.

Pictured here are the Atlas BT13, a keyhole style rail I got of eBay, and an Atlas BT34.

My goal is to have picatinny slots as far forward as I possibly can while retaining as much strength as I can. So, screw hole positioning is critical.

Out come the rulers...

I've got 3 inches until the curve starts and the stock gets thicker.

Remember that sports car analogy? Well, here's where things get interesting. ***The front of the stock, the thinnest part, has also been shaped with a concave curve into it.*** Not only that, but it's convex as well (right to left). Two opposing curves at two opposite angles = challenge!

Off comes the stock and out comes the blue painters tape! It's time to start making landmarks. First I mark the forward edge of the bottle curve. This is where the stock quickly gets thick. and I can get a good anchor point.

OK, lots going on in this next pic....

I'm concerning myself with locating the rear screw only. I'm fighting the front edge of the bottle curve and the rear edge where the fill port scalloping is (that's the oval shape drawn on the tape). Overall, I only have 1 inch of space to work in. But, I'm also fighting the diameter of the T-nut which I plan to use. This one has a slightly smaller diameter than the ones supplied by Atlas. I picked it up at a hardware store.

That little "I" or "H" in the center signifies the max point at which I can drill rearward and forward as well as a "mock" centerline. So, that 1 inch I had is really only 1/4". I guess that makes it easy! Due to limitation of space, the rear goes here. End of story!

The ebay rail is a fail. Bitter-sweet, really. It would have been nice to have all those slots but it's got a flat bottom and would have been a lot of work.

The short Atlas will work just fine. Just sucks that it's so far back and so short.

Looks like it's going to be the longer Atlas rail but, forward of backwards?

Ultimately, I mounted it like the first pic. It gives me less slots at the very tip of the tongue. I did this purposely to stop myself from mounting the bipod so far forward that it would put extra strain on the wood.

With the rail located and marked, it's time to start modifying the picatinny rail. Remember those two opposite and opposing curves I talked about earlier?

I mounted the rail to some scope mounts to give myself something to hold onto and to help keep the rail level. Then, headed off to the table top sander to shape the bottom of the aluminum rail.

I took it further than this but, it shows pretty well what I was after.

I re-taped, found the center line, and finalized my markings.

Then, sand, test, sand, test, sand, test, Ouch! HOT! Cool it off. sand, test, sand, test...

Once I was happy with the rail, I started into the drilling process.

I won't go into detail on this as I've covered it a few times in the past.

Thread link Video link

This is a jig I made in order to support the laminated wood from splitting. I used scrap wood to cut out the shape of the tongue, then cut it down the middle to remove some material. Screwed it to another block of wood to allow the sides to swivel and clamped it in place. It's a lot of work to go through but, it supports the whole front end of the stock from splitting.

You might wonder why I didn't just use the clamp alone. Well, along with those opposite and opposing curves, the tongue also has a taper to it! That makes it nearly impossible to properly clamp using a clamp alone. There's a lot of angles going on in this little section of the stock! Just finding the true center line was an exercise!

When I put the wood screw in, I applied a little wax to it. This was to help it cut threads into the wood a little easier. I also treated it like a tap where I slowly worked it in a little and then backed it out a little, then slowly in and back out...

I lost a little finish but, I'm not worried about it. It's on the inside, and I'll never see it.

This is really meant to show how much of the wood screw needed to be cut off.

Final install of the rail. Wood screw in the front, machine screw in the back.

That is one DEEP hole for the T-nut! It had to be in order to clear the bottle.

Take a moment to think about the forces being applied by the bipod. Overall, it's downward force from the weight of the rifle. But, with the legs at a 45º angle, there's a twisting force involved as well. The back anchor bolt could be experiencing a "pulling" force and the front could be experiencing a "pushing" force. Because of this, I think of the rear bolt as the work horse, holding all the weight, and I think of the front screw as a guide, just keeping things in line.

I don't beat the heck out of my rifles or go running around playing commando with them. Primarily it will sit on a bench and shoot just like whats pictured above. So, there is plenty of support here for what I do.

Thanks!

Hope you enjoyed my story!

Tom