Gulp, I never envisioned that someday I'd be asking other grown men to help with a mating problem but I'm perplexed and need some good advice...

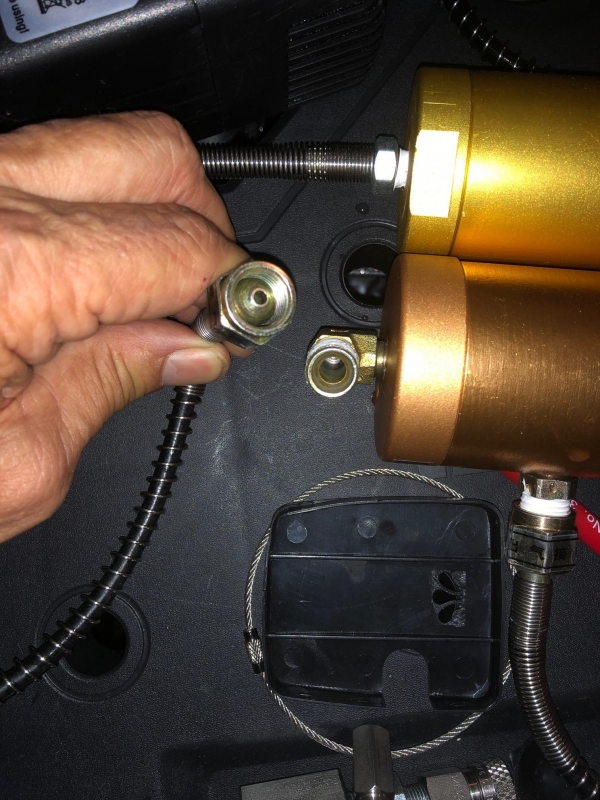

Okay, I'm adding a Coalescing Filter the my Sieve Filter and am not getting a good seal on the fitting. As best I can tell the male and female assemblies "should" mate together but I can hear a leak as I start to pressurize the filters. I suppose I could get two Crescent wrenches and really crank down in a attempt to put extra friction on the "metal on metal" connection but I get the feeling I'm missing something here.

I would appreciate your advice and counsel, Mate

Michael

Okay, I'm adding a Coalescing Filter the my Sieve Filter and am not getting a good seal on the fitting. As best I can tell the male and female assemblies "should" mate together but I can hear a leak as I start to pressurize the filters. I suppose I could get two Crescent wrenches and really crank down in a attempt to put extra friction on the "metal on metal" connection but I get the feeling I'm missing something here.

I would appreciate your advice and counsel, Mate

Michael