Recently acquired a HW55T that was a little tired. I made an adapter and popped on a synthetic seal at first, then decided to try and go back original and replace the leather piston seal. Didn't want to order one, so I got an idea and whipped one out with junk I had on hand.

Here's the synthetic seal adapter:

Here's my leather seal manufacturing tools. Anybody recognize the silver part of my die? Hint: it's 25mm on the inside :

:

Had to make a new center spacer/retainer thing too as it was obliterated. The gun lost only 10fps with the leather seal believe it or not. Popped in a new spring of reasonable dimensions and it's spitting out 7gr RWS wadcutters at 630fps. Shoots like a laser!

Weihrauch put a lot of thought into these guns to make them shoot as good as they do. The piston is featherlight, the shell is thinner and it has a second cocking slot cut into the opposite side. The nose is also aluminum to save weight:

A piston this light would be very prone to bounce. One way to get around that is to fit a high-preload spring. The other way, is to open the transfer port to keep peak pressure down. The transfer port here is a healthy 4mm, and around an inch long. That's a lot of dead space and it eliminates bounce/surge perfectly and without the harsh shot of a heavy spring. The downside, is limited power. But that's okay, these things are the smoothest shooting spring gun you'll ever shoot.

So you may be thinking, "What if the transfer port was 3mm like all the other guns? Would it boost power since the peak compression is higher?"

Well I thought that, so decided to see what would happen. I turned up a brass reducer for the transfer port that was a light tap fit. It will tap in easily, stay in place, but tap right back out with no harm later. Here we go:

Well it worked. Boosted power with the synthetic seal by 20fps. But, just as predicted bounce was pronounced and accuracy diminished. So out it came, back to stock and sweet shooting! No harm done, and now we know!

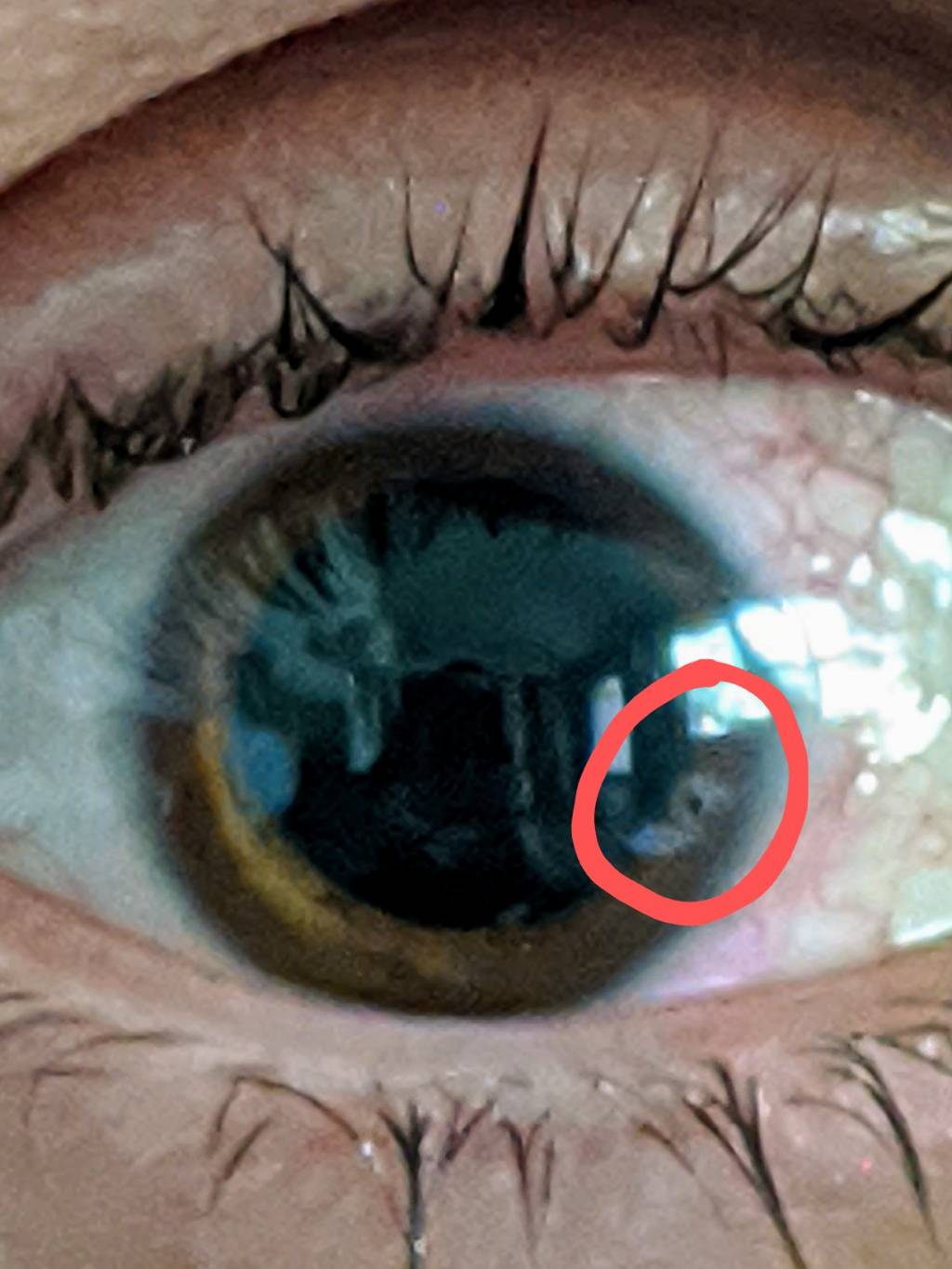

Anyway, I'm just rambling sitting here with one eye taped shut. Maybe someone finds this interesting. Wear your safety specs kids!

Here's the synthetic seal adapter:

Here's my leather seal manufacturing tools. Anybody recognize the silver part of my die? Hint: it's 25mm on the inside

Had to make a new center spacer/retainer thing too as it was obliterated. The gun lost only 10fps with the leather seal believe it or not. Popped in a new spring of reasonable dimensions and it's spitting out 7gr RWS wadcutters at 630fps. Shoots like a laser!

Weihrauch put a lot of thought into these guns to make them shoot as good as they do. The piston is featherlight, the shell is thinner and it has a second cocking slot cut into the opposite side. The nose is also aluminum to save weight:

A piston this light would be very prone to bounce. One way to get around that is to fit a high-preload spring. The other way, is to open the transfer port to keep peak pressure down. The transfer port here is a healthy 4mm, and around an inch long. That's a lot of dead space and it eliminates bounce/surge perfectly and without the harsh shot of a heavy spring. The downside, is limited power. But that's okay, these things are the smoothest shooting spring gun you'll ever shoot.

So you may be thinking, "What if the transfer port was 3mm like all the other guns? Would it boost power since the peak compression is higher?"

Well I thought that, so decided to see what would happen. I turned up a brass reducer for the transfer port that was a light tap fit. It will tap in easily, stay in place, but tap right back out with no harm later. Here we go:

Well it worked. Boosted power with the synthetic seal by 20fps. But, just as predicted bounce was pronounced and accuracy diminished. So out it came, back to stock and sweet shooting! No harm done, and now we know!

Anyway, I'm just rambling sitting here with one eye taped shut. Maybe someone finds this interesting. Wear your safety specs kids!