The ShoeBox was in the garage filling a 60 min Drager tank last night. I stepped out ever 20 min or so to check on it. It was at about 4300 psi so I figured I would give it a few more min to get a little closer to a full fill. When I opened the garage door It happened. BOOM! Instant dust storm. I thought the tank exploded. But it was the microbore hose. The bearing ring on the female foster fitting blew apart. I started out to shut the valve off to save some air, but thought twice. You know when you drop the wand at the car wash and try to pick it up without getting whipped? Well multiply that by 10 fold. Other than loosing 4000 psi of air, the whipping hose broke out a couple pieces of the milk crate the compressor was sitting on, snapped off the 3/8” Air hose feed to the ShoeBox, the desiccant and filter kits and beat the crap out of the bandsaw sitting next to it. Could have been a lot worse if it would have happened 2 seconds later!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Loud boom in garage is never good

- Thread starter Quad82

- Start date

My biggest fear. 4000 + psi is no joke. Even 3000 can still be dangerous. Glad no one got hurt

Upvote 0

Glad you weren't next to it!

High psi is dangerous forsure.

But hell even 100psi is dangerous for the right person

High psi is dangerous forsure.

But hell even 100psi is dangerous for the right person

Upvote 0

That's why I always stay away from my Yong Heng compressor when its running.

This is not the first time I hear about foster fittings failing. can you post some pictures of the failed parts showing how it fails ? is the ring of the female part torn apart ? or the balls run over the male stem ?

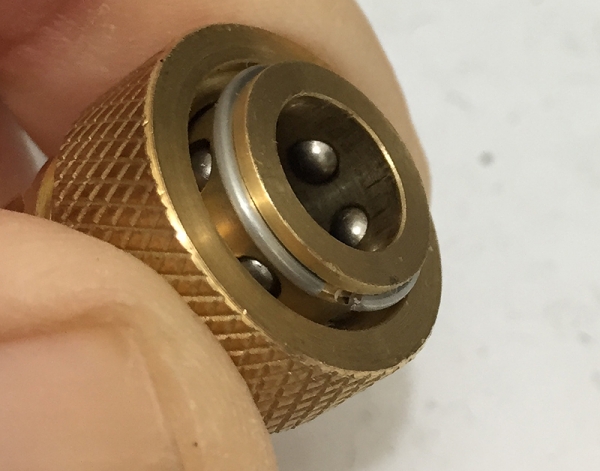

I have been using 8mm stainless steel quick connectors from China and I recently noticed that there are some dents at the edge of the groove on the male side. Clearly they are made by the balls on the female side when the assembly is under a high pressure of 4500 psi. I have got male connectors from a couple of Chinese vendors and despite of the fact that they are all made of stainless steel, one of them is obviously softer as the dent is deeper. For that particular male connector, the balls on the female side were jammed in place when it was used for the first time and I had to use quite a bit of force to pull back the ring and disengage it. What concerns me is not so much the dents but how close they are to the edge of the groove on the male connector. Given sufficient time, there is a high likelihood that the balls will run over the male stem and the connection will explode.

I will post some pictures later.

This is not the first time I hear about foster fittings failing. can you post some pictures of the failed parts showing how it fails ? is the ring of the female part torn apart ? or the balls run over the male stem ?

I have been using 8mm stainless steel quick connectors from China and I recently noticed that there are some dents at the edge of the groove on the male side. Clearly they are made by the balls on the female side when the assembly is under a high pressure of 4500 psi. I have got male connectors from a couple of Chinese vendors and despite of the fact that they are all made of stainless steel, one of them is obviously softer as the dent is deeper. For that particular male connector, the balls on the female side were jammed in place when it was used for the first time and I had to use quite a bit of force to pull back the ring and disengage it. What concerns me is not so much the dents but how close they are to the edge of the groove on the male connector. Given sufficient time, there is a high likelihood that the balls will run over the male stem and the connection will explode.

I will post some pictures later.

Upvote 0

You didn't mention where the hose and QD came from. Be careful about some of the cheap offerings from China. Some are only thin, nickel plated brass with a pressure rating of 1500 PSI. They're OK for paintball but not PCP use.

Upvote 0

China's metallurgy is moving along but still has a LONG way to go to earn any trust. Went through the same thing with Japan in the 1950's and 1960's. Now their products are world class. China is moving slower because as long as all the product produced is selling there is no incentive for improvement. Quit buying it and they will have to fix it.

To prevent occurrences such as yours a foster with an internal flow restrictor might be in order.

To prevent occurrences such as yours a foster with an internal flow restrictor might be in order.

Upvote 0

I have SloFlo valves from ExperHPA on both my tanks. Even without a hose, it limits the speed the air comes out. I think a valve like this would have prevented the damage from the hose whipping around.

Upvote 0

I just bought this from Smelliexpress. I replaced the male Foster with one with a check valve so if anything springs a leak or bursts up-stream of the tank, I don't lose any air. I also use a check valve on the compressor end so I can stop or bleed it without losing the air in the filter and hose. https://www.aliexpress.com/item/PCP-Air-Refill-HP-Fill-Station-300Bar-Din-Valve-G5-8-for-Carbon-Fibre-Cylinder-Filling/32812771109.html?spm=a2g0s.9042311.0.0.33254c4d9ZWruJ  Cheap insurance and no Orings except at the bottle. I'm sure you could find something like this for a CGA-347 type valve. It's only useful for filling your tank. It won't work as a fill adaptor for your gun.

Cheap insurance and no Orings except at the bottle. I'm sure you could find something like this for a CGA-347 type valve. It's only useful for filling your tank. It won't work as a fill adaptor for your gun.

Upvote 0

Brown shorts moment indeed! Thanks for the good wishes. Sorry, I didn’t take pictures. Was hurrying around trying to clear the dust storm out of the garage, pick up the mess and calm my wife down a bit. Everything went in the trash. It defently shook the windows. The hose was a AV double ended female foster microbore one. Ya, the $60 or $70 one. I have had it for a year with no issues. It stays on the ShoeBox and is only for filling tanks. So it doesn’t get the heavy on off use the the others do. I check both ends of the fittings every time I hookup. It’s the only hose I buy or use after having several cheep ones pop off a rifle while filling. I always have my hand on the valve to shut the tank off when filling. But the hose still whips around pretty violently. I just think about all the times I have my rifles teathered to the tank. Sometimes 3 hoses between the rifle, reg and tank. And I am lying next to them shooting. Scary stuff for sure.

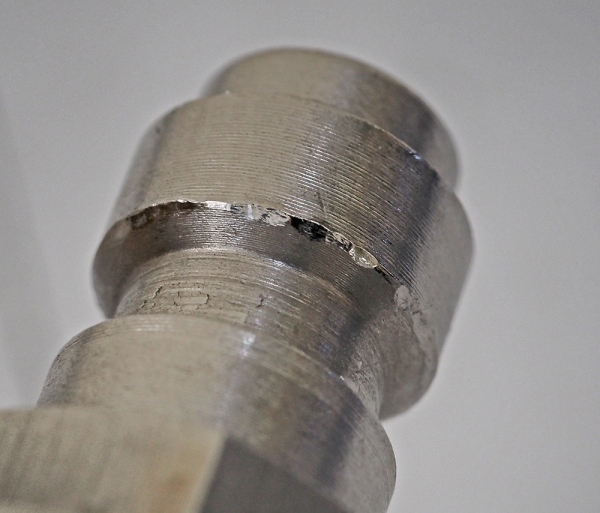

Almost forgot. The ring that holds the bearings in is what blew off. Yes, there are dents in the male fitting too. But it didn’t just push the bearings off the male end. It actually blew bearing retaining ring off the foster fitting. Wish I would have taken pictures. But the metal of the fitting itself actually broke into.

Almost forgot. The ring that holds the bearings in is what blew off. Yes, there are dents in the male fitting too. But it didn’t just push the bearings off the male end. It actually blew bearing retaining ring off the foster fitting. Wish I would have taken pictures. But the metal of the fitting itself actually broke into.

Upvote 0

Here is the pictures of the Chinese quick connectors mentioned in my previous post :

Dents on the male connector after used with the stainless female connector :

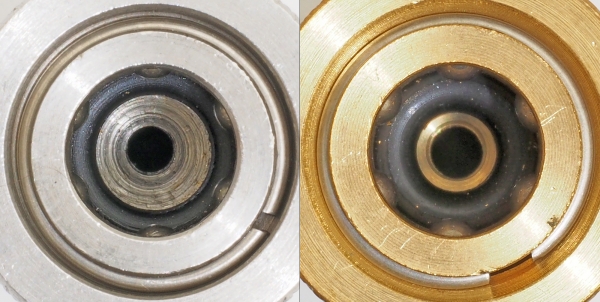

How far the balls stick out in stainless ( left ) and brass ( right ) female connector :

It is quite scary to see that only the very edge of the groove on the male connectors is used to hold it in place. I have got two types of female connectors – stainless and brass. I use the stainless type in my set up because I thought the metal is stronger. However, this is likely to be neutralized by the fact that the balls do not stick out as much as those in the brass type ( see the pictures ) so the grip on the male part is less secured. I am now looking for a stainless type that has the balls sticking out more.

Quad82 reported that the retaining ring of the female connector was blown off but I cannot imagine what force could have caused such failure. When under pressure, the ring is only subject to outward radial force exerted by the balls and the friction between the balls and the inner wall of the ring should be high enough to hold the ring in place.

When not in use the retaining ring is only held in place by a thin C-ring. On my stainless connector, that C-ring is on the lose side and can be removed just by using my fingers . On the brass connector, the fitting is a lot better and looks more secured. May be there are some fitting problems at this spot in the connector that has blown up ?

Dents on the male connector after used with the stainless female connector :

How far the balls stick out in stainless ( left ) and brass ( right ) female connector :

It is quite scary to see that only the very edge of the groove on the male connectors is used to hold it in place. I have got two types of female connectors – stainless and brass. I use the stainless type in my set up because I thought the metal is stronger. However, this is likely to be neutralized by the fact that the balls do not stick out as much as those in the brass type ( see the pictures ) so the grip on the male part is less secured. I am now looking for a stainless type that has the balls sticking out more.

Quad82 reported that the retaining ring of the female connector was blown off but I cannot imagine what force could have caused such failure. When under pressure, the ring is only subject to outward radial force exerted by the balls and the friction between the balls and the inner wall of the ring should be high enough to hold the ring in place.

When not in use the retaining ring is only held in place by a thin C-ring. On my stainless connector, that C-ring is on the lose side and can be removed just by using my fingers . On the brass connector, the fitting is a lot better and looks more secured. May be there are some fitting problems at this spot in the connector that has blown up ?

Upvote 0

The brass type fitting in your photo, I assume is one of the ones supplied with the Chinese filters. They have thicker walls and tighter tolerances than the stainless or other type, Foster fittings. I doubt if one of those will ever fail as long as it is married with the same spec male plug. I was not criticising the Chinese stuff in my last post. I was just pointing out that there is some product that is only made for paintball and there is also some very well made stuff that is as good as you will find anywhere and the good stuff does not always cost more than the bad stuff, you just need to sort the wheat from the chaff. Unfortunately for the true believers, the sticker, made in the USA, doesn't guaranty quality or even that it was made there, as with the AV branded item that is the subject of this discussion.

Upvote 0

The brass type fitting in your photo, I assume is one of the ones supplied with the Chinese filters.

Yes, the brass type came with my Yong Heng and gold filter. The stainless type was brought separately from another vendor

Upvote 0

I recently bought an Alpha-Carette Compressor. Are there any safety procedures to follow. Reading this is pretty scary.

Upvote 0

Yeah, I start loosing some comfort above 4000. My 457 Extreme & Great White take 4500. I have had gauges blow, nothing else. When I first got started in PCP , my nitrogen tank came with 5500 psi. I remember putting the regulator on it and opening the tank valve, feeling the valve raise up in hand gave me the utmost respect for it. In my line of work I have worked around compressed gas tanks/bottles in the 2500 psi range, so I was somewhat accustomed to high psi, but 5500-6000 is a whole new ball game. Evrytime I get a new gun, I fill it very slow.

Upvote 0

I have a Bauer with auto shutoff and I leave the room when filling. I also rely on quality hoses and fittings from Joe Brancato. Money well spent.

Upvote 0

Did I read a while back about another failure of an AV hose foster fitting? Sure sounds familiar.

Upvote 0

Had the same thing happen. Fitting came as part of SCBA fill assembly from China. Was suppose to be rated at 5000 psi.

Upvote 0

I have a pcp pistol that I converted from co2. It has a piece of macro line from the tank to the valve. I was sound asleep one night when I awoke startled to this loud bang and whooshing sound nearby scared the crap out of me. Once I gathered my thoughts from being so rudely awakened I figured it could only be the macro line and when I checked sure enough it was. The line was only good for the 850psi max I was using it for and I had left the valve opened so it was pressurized at it's limit all night. So I picked up on some 2500psi line and replaced the weak stuff. I will have to admit It was pretty exciting for a few seconds as the line that burst was only ten feet away from me.

Upvote 0

Take a look at my fill connections from my tank to my gun. Too many connectors to many places for leaks and failures. Yet this is pretty standard stuff

Upvote 0