You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Let's see those polished barrels? Inside and out?

- Thread starter Jld1969

- Start date

Funny you write this thread, as I just polished the inside of my barrel. I don't have a way to take a photo of the inside but believe me it's super clean!

First, I cleaned the barrel using Balistol on a patch with brass brush rotating wet and dry until clean. Second, I used some JB bore paste mixed with Kroil oil with one of those caliber sized cotton thingies you screw onto a rod for 20 passes.

Lastly, I finished off the barrel using dry patches to remove the excess paste from the barrel and running a damp Balistol patch to leave a light sheen behind. Works like magic and cuts down on the next cleaning.

First, I cleaned the barrel using Balistol on a patch with brass brush rotating wet and dry until clean. Second, I used some JB bore paste mixed with Kroil oil with one of those caliber sized cotton thingies you screw onto a rod for 20 passes.

Lastly, I finished off the barrel using dry patches to remove the excess paste from the barrel and running a damp Balistol patch to leave a light sheen behind. Works like magic and cuts down on the next cleaning.

Upvote 0

I won't go into polishing the bore , But as for the outside , proper technics are so important too ! One can fudge a good barrel if done wrong (warp by uneven heating). There are three methods that are acceptable .

Using a barrel spinner and belt sanding with high grit belts in sucsession . Reccommended .

By hand and sanding in line with the bore . This is called "carding" . Also takes much more work .

Lastly is with a buffer machine , but is not to be taken lightly and can be very dangerous if done wrong . It must be fed linear while rotating at the same time . Professionals only ....

Steve

To be clear ; I am talking about the Outside , not the inside .

Using a barrel spinner and belt sanding with high grit belts in sucsession . Reccommended .

By hand and sanding in line with the bore . This is called "carding" . Also takes much more work .

Lastly is with a buffer machine , but is not to be taken lightly and can be very dangerous if done wrong . It must be fed linear while rotating at the same time . Professionals only ....

Steve

To be clear ; I am talking about the Outside , not the inside .

Upvote 0

3M makes jewelry cloths Ernest Rowe did a video on it you can find it on YouTube. I would not recommend equipment to do the polishing unless you are a professional what I am talking about is cleaning and polishing nothing heavy duty all hand work. Am sure the will be lots have opinions on if it really works or technique accuracy issues all the above in my experience from having a done professionally it makes a huge difference using the soft jewelry cloths makes a big difference and it's very simple if you don't want it done professionally.

Upvote 0

I just came across a screen shot I took from SPAW’s FB months ago. I thought about posting it here as I never saw any follow up info on FB. Perfect timing.

I will definitely have to look into this. I would love to try this on a FX liner.

I will definitely have to look into this. I would love to try this on a FX liner.

Upvote 0

Polishing the outside to improve harmonic . I would have to whole heartedly say "no" . Save your money , get more trigger time .

Harmonics is more about vibration traveling down the barrel . The proper harmonic tune is having the vibration "node" passing through the barrel at the muzzle .

Harmonics is more about vibration traveling down the barrel . The proper harmonic tune is having the vibration "node" passing through the barrel at the muzzle .

Upvote 0

I won't go into polishing the bore , But as for the outside , proper technics are so important too ! One can fudge a good barrel if done wrong (warp by uneven heating). There are three methods that are acceptable .

Using a barrel spinner and belt sanding with high grit belts in sucsession . Reccommended .

By hand and sanding in line with the bore . This is called "carding" . Also takes much more work .

Lastly is with a buffer machine , but is not to be taken lightly and can be very dangerous if done wrong . It must be fed linear while rotating at the same time . Professionals only ....

Steve

Airgun barrels do not need heavy machinery and should never be used inside a airgun barrel for a cleaning or polish!! Also, why? These aren't burnt powders being embedded in the barrel only soft lead residue! One can F-up something really bad once you start to go over the top.

Upvote 0

i think the inside should be nice and clean the outside is a waste of time don't see any need for it

Upvote 0

i think the inside should be nice and clean the outside is a waste of time don't see any need for it

+1

Upvote 0

Polishing the outside to improve harmonic . I would have to whole heartedly say "no" . Save your money , get more trigger time .

Harmonics is more about vibration traveling down the barrel . The proper harmonic tune is having the vibration "node" passing through the barrel at the muzzle .

I misread your comment and I apologize for the wrong response to your comment!

Upvote 0

Airgun barrels do not need heavy machinery and should never be used inside a airgun barrel for a cleaning or polish!! Also, why? These aren't burnt powders being embedded in the barrel only soft lead residue! One can F-up something really bad once you start to go over the top.

He said he likes his stuff shiny , it's fine for stainless steel . Or it could be bead blasted for a mat finish . If he wanted a shiny steel barrel it could be clear coated to protect it from oxidizing . Again we're talking about the outside ; not the inside .

Steve

Upvote 0

Upvote 0

Yes sir, choked. It was a barrel with about 1/2" of damaged rifling at the end so I cut off the bad portion and faced it off in the lathe, and then crowned it manually with a handheld drill and brass screw.

Upvote 0

For the bore - you can start with JBB if needed, and then these on mop - https://kentsupplies.com/beading-and-jewelry-tools/polishing-paste/oil-based-lapping-paste/13-pieces-set-of-20-gram-diamond-lapping-paste-polishing-compound-grits-0.25-to-40-microns.html

I like using the Dewey rods when polishing on my lathe. Using 17 cal rods for 22 cal, and larger for my 30 cal barrels.

You can push some pellets through to find rough patches (if you don't have a good borescope / endoscope) to figure out where to spend some extra time for polishing.

Just be careful with the muzzle crown, and be prepared to clean it up afterwards.

I like using the Dewey rods when polishing on my lathe. Using 17 cal rods for 22 cal, and larger for my 30 cal barrels.

You can push some pellets through to find rough patches (if you don't have a good borescope / endoscope) to figure out where to spend some extra time for polishing.

Just be careful with the muzzle crown, and be prepared to clean it up afterwards.

Upvote 0

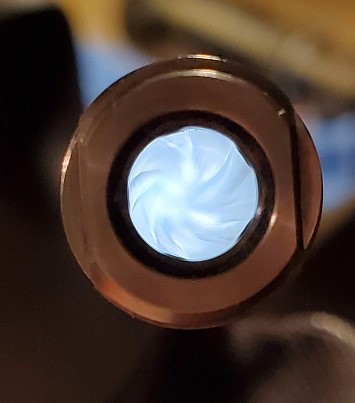

Here's one I did this week. Getting a picture of the bore is beyond my abilities apparently.

That was after J-B Bore Compound followed by Bore Bright.

And the new crown:

That is one nice looking barrel and crown. Decent picture as well it's not easy to get a good pic of the inside and crown of a barrel like that.

Upvote 0

sonny and nervoustrig That's a good photos of the inside of the barrels looks awesome good job. I lime the look of a polished barrel on the outside on the LCS is exposed so you can see most of it and it just makes the look more expensive and clean. But other barrels lime the inpact and all Fx is not visible and I understand why some guys don't want to polish them but for me I like the smooth clean shiny look it makes it easier to index and take in and out. But that's just my opinion thank you to all who joined in on this topic.

Upvote 0

I have an idea for an experiment . " Fire lapping " . With powder burners fire lapping is done with pretreated bullets coated with various grits of compound impregnated to the bullet . Another way is to put the compound on a metal plate then the bullet and another plate on top , gently roll the bullet between the plates to cover the bullet with the compound . Then fire the coated bullets .

I'm wondering if this same technic would work with felt cleaning pellets ..... I have some spare barrels I could use for testing . The hard part will be to photograph the progression through the bore scope , but should be possible . I think slugs would work better , I could do both for comparision . Maybe a combination of both ; slugs for the lower grit compound to smooth out imperfections followed by the felt cleaning pellets with the finer grit abrasive for the polished finish .

I'll start a new thread for this if there is enough interest . I could do chrony data of before and after as well .

Opinions and Ideas for testing parameters.

Update : Check out this guy's idea .... But use Cerrosafe instead of lead . The Cerrosafe will actually shrink alittle after cooling . It should smooth out the imperfections in the lands without enlarging the groove diameter .

https://www.youtube.com/watch?v=Z6EYk-oZEsc

Cerrosafe can be purchased from Brownells.com

https://www.brownells.com/gunsmith-tools-supplies/barrel-tools/barrel-chamfering-accessories/1-2-lb-cerrosafe-sku080027050-384-1743.aspx

Here is the video from Ernest Rowe on bore polishing .

https://www.youtube.com/watch?v=Gkg_2v2X3Ac

I'm wondering if this same technic would work with felt cleaning pellets ..... I have some spare barrels I could use for testing . The hard part will be to photograph the progression through the bore scope , but should be possible . I think slugs would work better , I could do both for comparision . Maybe a combination of both ; slugs for the lower grit compound to smooth out imperfections followed by the felt cleaning pellets with the finer grit abrasive for the polished finish .

I'll start a new thread for this if there is enough interest . I could do chrony data of before and after as well .

Opinions and Ideas for testing parameters.

Update : Check out this guy's idea .... But use Cerrosafe instead of lead . The Cerrosafe will actually shrink alittle after cooling . It should smooth out the imperfections in the lands without enlarging the groove diameter .

https://www.youtube.com/watch?v=Z6EYk-oZEsc

Cerrosafe can be purchased from Brownells.com

https://www.brownells.com/gunsmith-tools-supplies/barrel-tools/barrel-chamfering-accessories/1-2-lb-cerrosafe-sku080027050-384-1743.aspx

Here is the video from Ernest Rowe on bore polishing .

https://www.youtube.com/watch?v=Gkg_2v2X3Ac

Upvote 0

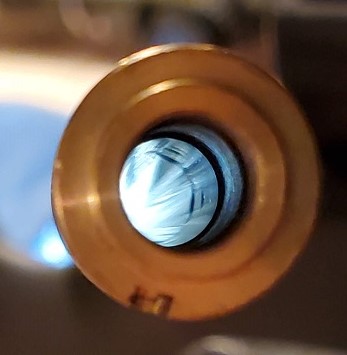

FX .25 Dreamline Classic. Was nice to clean her up all pretty!

Removing the throughput in the barrel would provide an additional speed of 8-10 m / s. Tested affair!

Upvote 0