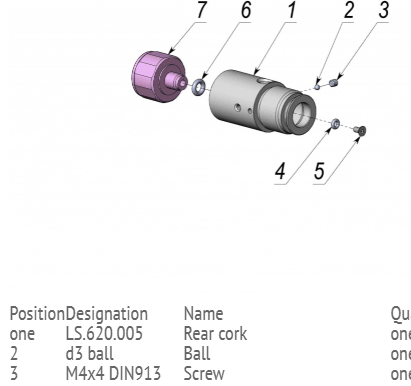

I had to use the secondary bleed screw back by the gauge on my Leshiy recently. I now have a slow leak and am getting bubbles around this screw after applying soapy water.

Thought I had seen a video on this but can't seem to find it.

I tried to snug up the screw a bit but was very cautious. No improvement.

Remove the screw completely and clean out the area? Anything else?

Thought I had seen a video on this but can't seem to find it.

I tried to snug up the screw a bit but was very cautious. No improvement.

Remove the screw completely and clean out the area? Anything else?