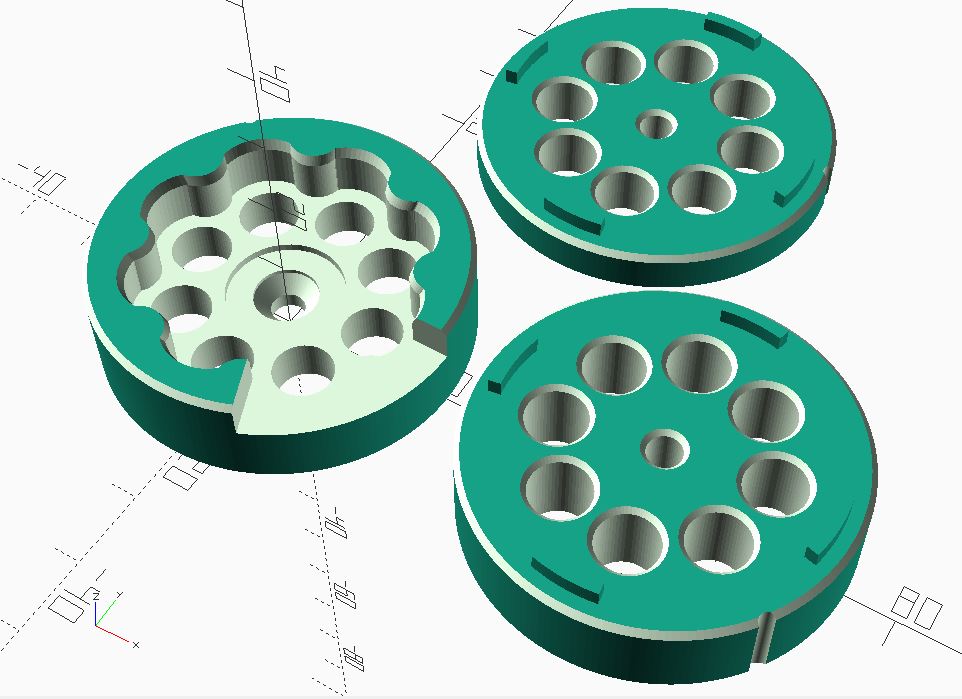

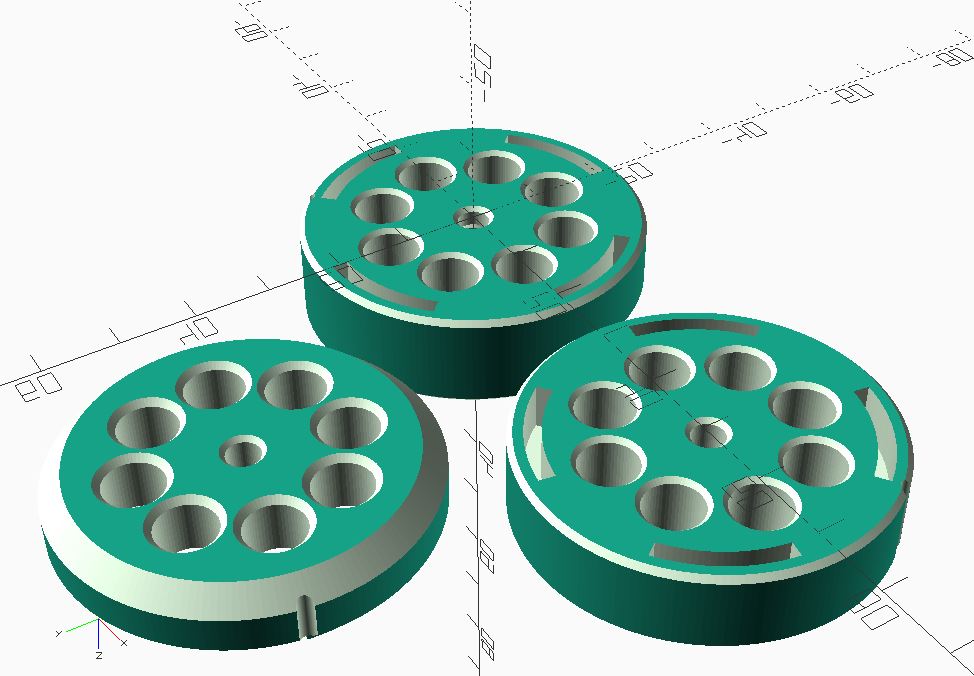

Designed a Speed Loader for L2, put a lot of work in this (OpenScad 397 code lines) to make it an easy print, my 3D printer is a home made reprap so any printer with a bed size from 150x150 mm should do

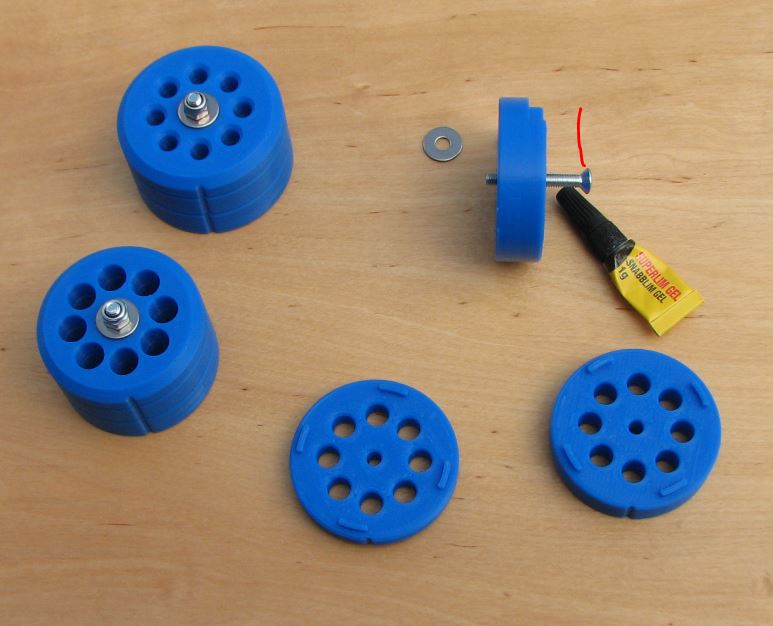

I designed it as simple as possible, you will only need the 3 printed parts, one 4mm x 30 screw with counter sunk head, a shim and a lock nut

The discs is held i position by friction between the printed parts, the lock nut is used to adjust this friction, no balls and springs

Ad glue to the head of the screw, this will make it stick to the adapter part

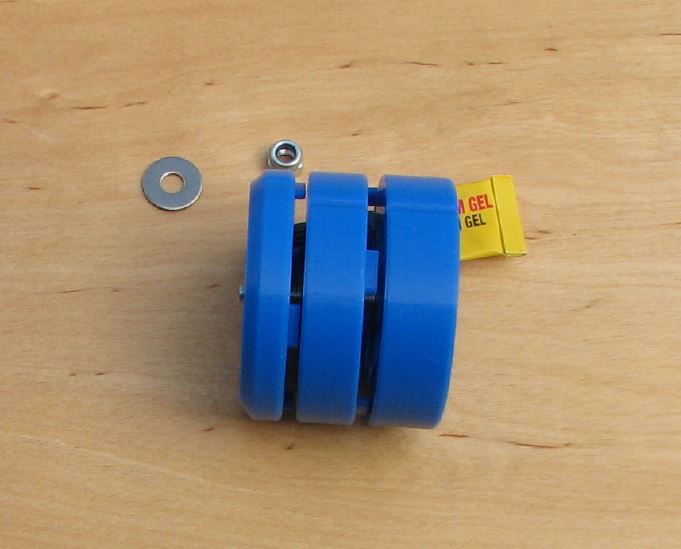

Put the parts together and tighten the nut and let the glue settle, (edit when dry, loosen the nut a bit and adjust the friction

when dry, loosen the nut a bit and adjust the friction

Turn left middle and upper discs and load pellets

Turn upper disc clock wise to drop the pellets to middle disc

Turn upper disc anti clock wise to lock

The speed loader is fixed by the L2 indexing arm so only one hand needed, turn clockwise to drop the pellets in mag

Load on Sunday, shoot all week

I designed it as simple as possible, you will only need the 3 printed parts, one 4mm x 30 screw with counter sunk head, a shim and a lock nut

The discs is held i position by friction between the printed parts, the lock nut is used to adjust this friction, no balls and springs

Ad glue to the head of the screw, this will make it stick to the adapter part

Put the parts together and tighten the nut and let the glue settle, (edit

Turn left middle and upper discs and load pellets

Turn upper disc clock wise to drop the pellets to middle disc

Turn upper disc anti clock wise to lock

The speed loader is fixed by the L2 indexing arm so only one hand needed, turn clockwise to drop the pellets in mag

Load on Sunday, shoot all week