FX Airguns is proud to announce the launch of it's new sister company:

Element Optics

Element Optics has been a work in progress for the last two years. The full backstory can be found at https://element-optics.com/a-plan-comes-together/ - (and really should be read to get the full scope of what Element is all about). Essentially it really came down to Fredrik at FX Airguns approaching Ted Bier and Matt Dubber with a proposition: Start an optics company, design a quality product based on a hand-picked team’s collective expertise, find quality manufacturers, and do all of this with the full backing of a global manufacturing giant, FX Airguns.

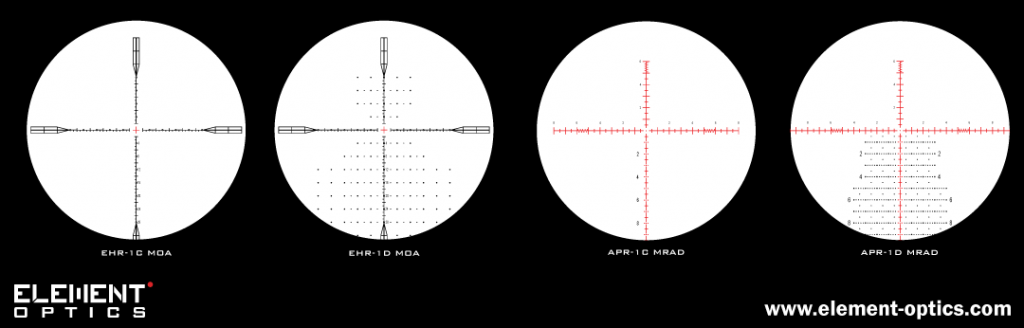

The team was put together including Matt Dubber, Ted Bier, Shane Kellar, Johan Axelsson, and other behind the scenes industry individuals with decades of experience (including Brad Bonar that many of you know from his 10+ years as head of sales for Hawke Optics USA). Ted and Matt have designed the reticles from the ground up trying to incorporate all the things that work for a reticle and none of the excess that often clutters the lens. Matt designing all the MRAD reticles and Ted designing all the MOA reticles.

As Matt puts it best in his blog article "Without an understanding of optics, your rifle is useless, and over the years we have all grown to understand the intricacies of riflescope design & operation with many, MANY different makes & models passing through our hands. Ted and myself in particular have worked with different manufacturers along the way - Everything from Hawke to Athlon to Nightforce. We fully understand the differences between a poorly-made cheapie and a high-end German or Japanese scope. We’ve done the reviews, the tracking assessments, the field tests. We’ve broken many, and found their failure points. We KNOW what makes a good riflescope good and a bad riflescope bad, and we KNOW what needs to be done to bring a solid, reliable product to the market without breaking the bank. And we’ve spent so much time talking to (and competing against) our YouTube audience that we know exactly what they need in a reticle design - Hence our involvement in the APR and EHR reticle families."

Enter Shane Kellar who had just transitioned to working at Utah Airguns. Shane has had extensive history working with scope manufacturing companies in his career. Matt & Shane jumped at the opportunity to travel out to Japan and China to visit manufacturing & testing facilities for meetings and Quality Control assessments. Shane and Matt spent weeks with designers, engineers, assembly teams and inspectors giving their feedback to manufacturers and implementing their own quality control checks. Element was very impressed with what they saw, and feel very confident about the future with the factories we have teamed up with. It's really the perfect combination and being fired up with visions of future growth and exciting projects, Shane joined Element Optics shortly afterwards on a full-time basis, adding valuable experience and fresh ideas to the team.

Last but not least to the Element Optics team, bringing the back end engineering and expertise, is Johan Axelsson. Johan, the son of Fredrik, is a technically-astute, incredibly intelligent designer who’s responsible for many of the recent innovations and advancements at FX Airguns. Johan grew up in his father’s footsteps, observing the process of product design & development from a young age and making his mark. Johan spends a lot of his time working on 3D CAD designs, testing prototypes and overseeing the engineering and manufacturing processes. Although most of the Element products and parts are manufactured and assembled in other facilities, Element knows how crucial it is to have their own equipment and machinery. Element has the bonus advantage of using Johan and FX Airguns with their engineering prowess to create internal scope parts that may need tighter tolerances than what the factories can provide.This keeps Element in full control, allowing them to design & test parts themselves, and giving insight into how different materials and components may work. This feedback loop between the designers and the factories keeps Element firmly in control, and regular visits ensure nothing happens without them knowing about it.

The results are staggering. Glass with clarity that far surpasses it's price point. Turrets that work exceptionally well; thanks to the stainless steel on stainless steel internals, reset-able zero stops on all models (even the entry level models - unheard of at the price point!), carefully thought out reticles designed by shooters who will subsequently create videos educating everyone how to use them and why they were designed, world class quality control, pricing that is far below comparable scopes in the market, and peace of mind thanks to a lifetime warranty that requires no registration, proof of purchase and can be transferred.

More info to be posted soon. Please go to Elements website at www.element-optics.com.

Follow Element Optics on Instagram at @element_optics

And on Facebook at @WeAreElementOptics

Element Optics

Element Optics has been a work in progress for the last two years. The full backstory can be found at https://element-optics.com/a-plan-comes-together/ - (and really should be read to get the full scope of what Element is all about). Essentially it really came down to Fredrik at FX Airguns approaching Ted Bier and Matt Dubber with a proposition: Start an optics company, design a quality product based on a hand-picked team’s collective expertise, find quality manufacturers, and do all of this with the full backing of a global manufacturing giant, FX Airguns.

The team was put together including Matt Dubber, Ted Bier, Shane Kellar, Johan Axelsson, and other behind the scenes industry individuals with decades of experience (including Brad Bonar that many of you know from his 10+ years as head of sales for Hawke Optics USA). Ted and Matt have designed the reticles from the ground up trying to incorporate all the things that work for a reticle and none of the excess that often clutters the lens. Matt designing all the MRAD reticles and Ted designing all the MOA reticles.

As Matt puts it best in his blog article "Without an understanding of optics, your rifle is useless, and over the years we have all grown to understand the intricacies of riflescope design & operation with many, MANY different makes & models passing through our hands. Ted and myself in particular have worked with different manufacturers along the way - Everything from Hawke to Athlon to Nightforce. We fully understand the differences between a poorly-made cheapie and a high-end German or Japanese scope. We’ve done the reviews, the tracking assessments, the field tests. We’ve broken many, and found their failure points. We KNOW what makes a good riflescope good and a bad riflescope bad, and we KNOW what needs to be done to bring a solid, reliable product to the market without breaking the bank. And we’ve spent so much time talking to (and competing against) our YouTube audience that we know exactly what they need in a reticle design - Hence our involvement in the APR and EHR reticle families."

Enter Shane Kellar who had just transitioned to working at Utah Airguns. Shane has had extensive history working with scope manufacturing companies in his career. Matt & Shane jumped at the opportunity to travel out to Japan and China to visit manufacturing & testing facilities for meetings and Quality Control assessments. Shane and Matt spent weeks with designers, engineers, assembly teams and inspectors giving their feedback to manufacturers and implementing their own quality control checks. Element was very impressed with what they saw, and feel very confident about the future with the factories we have teamed up with. It's really the perfect combination and being fired up with visions of future growth and exciting projects, Shane joined Element Optics shortly afterwards on a full-time basis, adding valuable experience and fresh ideas to the team.

Last but not least to the Element Optics team, bringing the back end engineering and expertise, is Johan Axelsson. Johan, the son of Fredrik, is a technically-astute, incredibly intelligent designer who’s responsible for many of the recent innovations and advancements at FX Airguns. Johan grew up in his father’s footsteps, observing the process of product design & development from a young age and making his mark. Johan spends a lot of his time working on 3D CAD designs, testing prototypes and overseeing the engineering and manufacturing processes. Although most of the Element products and parts are manufactured and assembled in other facilities, Element knows how crucial it is to have their own equipment and machinery. Element has the bonus advantage of using Johan and FX Airguns with their engineering prowess to create internal scope parts that may need tighter tolerances than what the factories can provide.This keeps Element in full control, allowing them to design & test parts themselves, and giving insight into how different materials and components may work. This feedback loop between the designers and the factories keeps Element firmly in control, and regular visits ensure nothing happens without them knowing about it.

The results are staggering. Glass with clarity that far surpasses it's price point. Turrets that work exceptionally well; thanks to the stainless steel on stainless steel internals, reset-able zero stops on all models (even the entry level models - unheard of at the price point!), carefully thought out reticles designed by shooters who will subsequently create videos educating everyone how to use them and why they were designed, world class quality control, pricing that is far below comparable scopes in the market, and peace of mind thanks to a lifetime warranty that requires no registration, proof of purchase and can be transferred.

More info to be posted soon. Please go to Elements website at www.element-optics.com.

Follow Element Optics on Instagram at @element_optics

And on Facebook at @WeAreElementOptics