G

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nice write up Chuck. I just received a superior liner and was going to switch it out after I got familiar with the new impact. I touched on this subject before, and I see you never mentioned it, but what about those orings? What are your recommendations on the orings that hold the liner? My question is do you use them and are they nessasary? Geoff

Upvote 0

Nice write up! I'm a little confused though but I may be missing something. Why do you loosen the grub screw on the block? The barrel housing is indexed by the bottom notch on the transfer port, the grub screw holds the barrel housing in place and I don't think it interacts in any way with the liner?

Upvote 0

KulaHi

I was wondering the same thing . That part didn't make sense to me either but I'm pretty new to the impact .

Dan

I was wondering the same thing . That part didn't make sense to me either but I'm pretty new to the impact .

Dan

Upvote 0

Wow, two great questions! To answer the first one regarding the barrel liner o-rings...I always remove the o-rings because there is really no good way of securing them so they are in the same place each time. Accuracy can be defined by one word: Consistency. So either leave them off or support the liner a different way that will remain consistent. One way of supporting the liner inside the barrel tube is to wrap tape around the liner in several spots until it just fits snugly into the barrel tube. This way it is supported the same way each time you take it out and put it back in. You might want to test your own rifle by shooting some groups without anything on the liner, and then with supports of some kind on your liner to see if there is any difference in your rifle's accuracy.

As to the second question: When you over tighten the grub screw on the rear block that holds your barrel tube in place, it pinches the barrel liner inside and makes it hard or even impossible to rotate or remove the barrel liner. So when you are going to rotate the liner to each of the new positions to shoot test groups it is important to loosen that grub screw first. Then of course you must remember to tighten it after you rotate the barrel liner to each new position. It seems that most people tend to over tighten screws and especially that grub screw. I have had dozens of guys over the last few years contact me to ask why they can't remove or rotate their barrel liner to index it, and it is always because that grub screw has been over tightened with an Allen wrench. Maybe this is why the original Impacts had a thumbscrew rather than an Allen screw?

One last thought to share...Once you get your liner indexed to the sweet spot that gives you the best accuracy, you can make a permanent registration mark so that you can remove it for cleaning and reinstall it to the exact same place each time. And each time you reinstall your liner it will shoot exactly the same way each time.

That totally makes sense now. Thank you for explaining!

Upvote 0

...To answer the first one regarding the barrel liner o-rings......So either leave them off or support the liner a different way that will remain consistent.

I replaced the liner original orings with harder NBR90 and secured with a Teflon tape.

But tinkering now taking out these hard orings and replace with very soft silicon sleeve bushings, to make the liner really "float".

Super soft silicon sheets, slice to let say 10mm width and wrap around the liner on tree places?

Upvote 0

Chuck, thanks for the great info on barrel indexing! I'm new to the "high end" world of air guns, just got an FX Impact Compact and love it.

I have been tuning it and think I am ready to do the indexing you describe. I have a question about the O rings on the barrel liner. I just added a Huma-air transfer port and pellet probe, when I was putting things back together the O rings on the barrel liner were impossible to position, I noticed you mentioned they could be left off, is this how you're setup or have you found another solution?

I will try to add a picture to this post showing what I did to finally get the O rings spaced, but I would rather leave them off if it doesn't make any difference. My barrel is just 500mm I used a piece of pipe hanger (holly iron, only made of plastic not metal) I cut a strip about 1/4 inch wide and 6 or 8 inches long then put a mark on it a few inches from the end. I could then use this between the barrel liner and the shroud to push the O ring into position using the mark I made as a reference to know how far in the O ring was. I could then know the O rings were both the same distance from each end of the barrel liner.

I have to assume that leaving the O rings off could lead to better accuracy same as a powder burner with a floated barrel. I'm very interested in your thoughts.

I have been tuning it and think I am ready to do the indexing you describe. I have a question about the O rings on the barrel liner. I just added a Huma-air transfer port and pellet probe, when I was putting things back together the O rings on the barrel liner were impossible to position, I noticed you mentioned they could be left off, is this how you're setup or have you found another solution?

I will try to add a picture to this post showing what I did to finally get the O rings spaced, but I would rather leave them off if it doesn't make any difference. My barrel is just 500mm I used a piece of pipe hanger (holly iron, only made of plastic not metal) I cut a strip about 1/4 inch wide and 6 or 8 inches long then put a mark on it a few inches from the end. I could then use this between the barrel liner and the shroud to push the O ring into position using the mark I made as a reference to know how far in the O ring was. I could then know the O rings were both the same distance from each end of the barrel liner.

I have to assume that leaving the O rings off could lead to better accuracy same as a powder burner with a floated barrel. I'm very interested in your thoughts.

Upvote 0

I wrap the o-rings with teflon tape to keep them in place, this also makes them a little more snug in the liner sleeve. I'm looking forward to retesting with the FX carbon fiber liner sleeve once it gets here.

Upvote 0

Good instructions Chuck, I indexed my Crown and finding the position where the pellets hit at 12 o'clock was the sweet spot as far as accuracy was measured. I have since wondered if indexing with the Moderator, Shroud, and retaining nut put back on after each index would make a difference.

Upvote 0

Chuck your instructions were clear and I am sure it will help quite a few people but as I am sure you are aware making any changes to the gun effects the harmonics so I was curious if you thought about testing the indexing with the complete assembly .

Upvote 0

Chuck I live in Ohio and spent most of my airgun hunting time chasing squirrels , I make down to Florida one a year to fish and bring along a airgun for the iguana .

Upvote 0

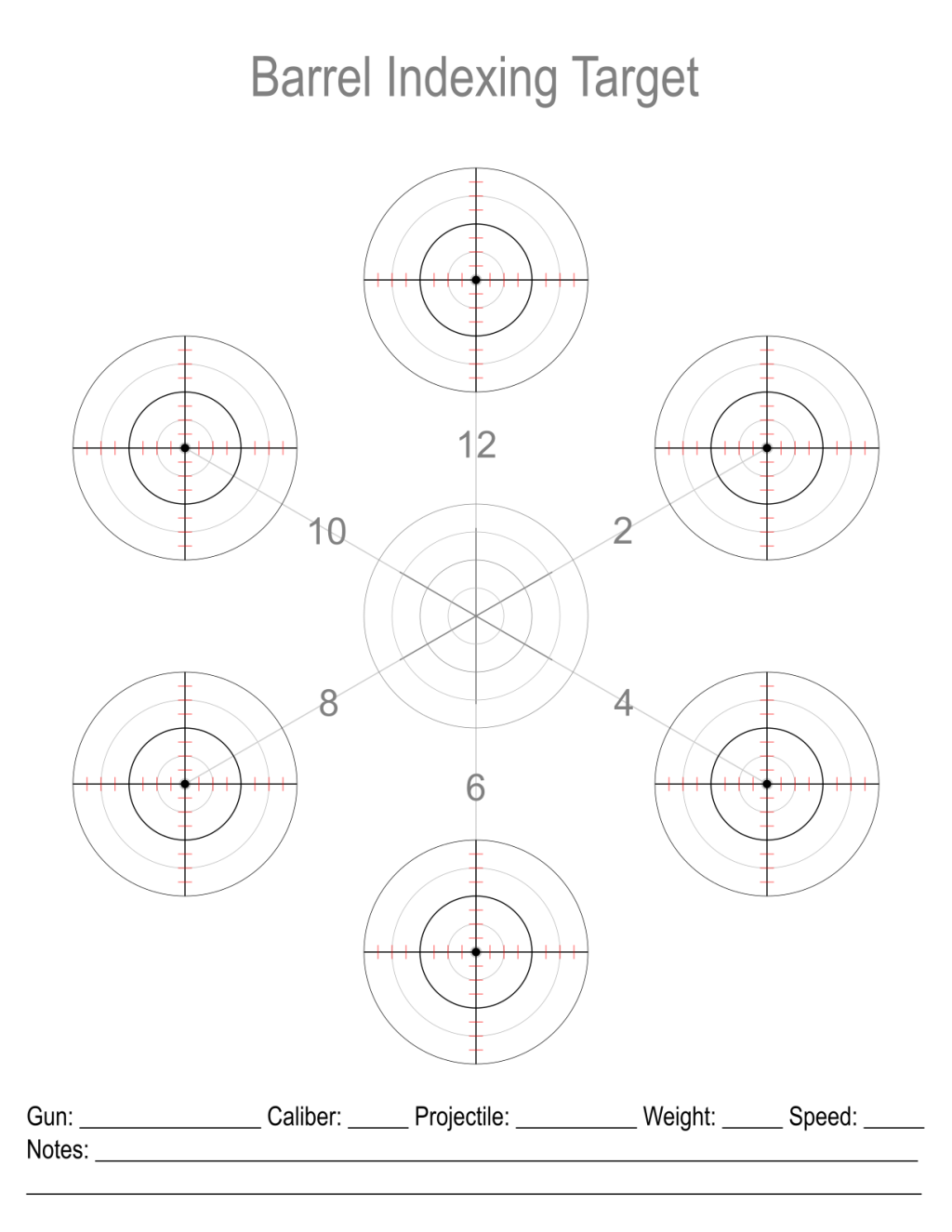

I was working on indexing my Impact mkII last weekend and kept forgetting which group went with which index on my barrel, so I created a target to use while indexing.

I print it at 8.5x11 and set it out at 50yds.

I print it at 8.5x11 and set it out at 50yds.

Upvote 0