The title says it all. Mods so far for 100 fpe...

Huma extra high pressure regulator.

3.25gram 4.47mm thick lead weight added to the hammer.

4.47mm hammer spring preload from the lead weight.

Delrin washer in place of the hammer bumper o-ring.

5.8mm valve seat from Earnest Rowe.

Ported valve housing, rear block transfer port, barrel transfer port and pellet probe.

I only get a tiny gain above 165 bar because I need more hammer weight. Right now The gun makes 100 fpe at 165 bar. I did some testing today under less than ideal conditions to see if the mods have harmed accuracy and the answer is, I don't think so. Shooting off the bipod at 60 yds in 4-12 mph winds blowing towards 2 o'clock with the target being 12. I got the same pre-mod groups that are normal for me. The best I can do is pull the trigger when the crosshair moves over the center, without a machine rest. The 5th shot opened up my .295 center to center group to .544. I was actually 2 fps short of 100 fpe with the average being 944 fps shooting JSB 50.15gr

I have a High power kit coming from Earnest Rowe at FX in a couple of weeks or whenever he has time to make it. I have no idea what it consists of. I also have 2 more pellet probes and barrel transfer ports coming in the same order. The pellet probe is the most restrictive part. The one I'm using right now has the floor removed where it contacts the pellet. I'm not sure how much more radical I can go on the probe without causing feeding problems. I'll update as I gain performance.

Please share your FX Impact tuning tips and tricks.... and opinions on this subject.

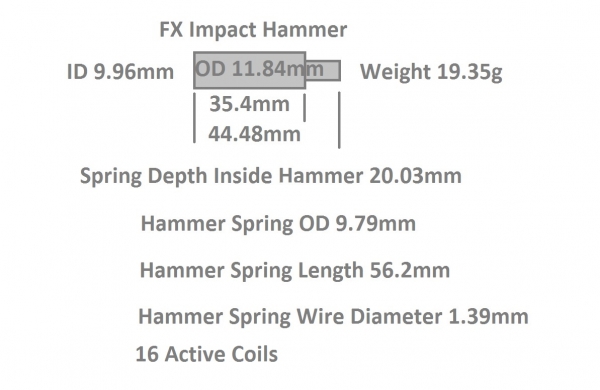

I'll include the OEM hammer and spring specs for reference.

Huma extra high pressure regulator.

3.25gram 4.47mm thick lead weight added to the hammer.

4.47mm hammer spring preload from the lead weight.

Delrin washer in place of the hammer bumper o-ring.

5.8mm valve seat from Earnest Rowe.

Ported valve housing, rear block transfer port, barrel transfer port and pellet probe.

I only get a tiny gain above 165 bar because I need more hammer weight. Right now The gun makes 100 fpe at 165 bar. I did some testing today under less than ideal conditions to see if the mods have harmed accuracy and the answer is, I don't think so. Shooting off the bipod at 60 yds in 4-12 mph winds blowing towards 2 o'clock with the target being 12. I got the same pre-mod groups that are normal for me. The best I can do is pull the trigger when the crosshair moves over the center, without a machine rest. The 5th shot opened up my .295 center to center group to .544. I was actually 2 fps short of 100 fpe with the average being 944 fps shooting JSB 50.15gr

I have a High power kit coming from Earnest Rowe at FX in a couple of weeks or whenever he has time to make it. I have no idea what it consists of. I also have 2 more pellet probes and barrel transfer ports coming in the same order. The pellet probe is the most restrictive part. The one I'm using right now has the floor removed where it contacts the pellet. I'm not sure how much more radical I can go on the probe without causing feeding problems. I'll update as I gain performance.

Please share your FX Impact tuning tips and tricks.... and opinions on this subject.

I'll include the OEM hammer and spring specs for reference.