The Impact Power Plenums managed to get to Australia just before c19 really slowed everything down.

Installing my kit I was unsure as to whether to use the original HS or the new shorter one supplied with the kit. . I had seen a few post from people not happy with the power they achieved with the new spring so I decided to go with my old longer spring.

With the old spring I had plenty of power (.22cal 26g slugs @ 970fps/ 125b)but also consistent pretension on the power wheel. Even on minimum with the adjuster screw backed out I couldn’t get any free play on the slider. It wasn’t tight but as soon as you started turning the power wheel it got tight after 1 or 2 clicks.

There are a couple of issues with it set up this way. 1 you lose your free floating hammer and 2 you have excessive wear on your power wheel. You don’t want to turn it with back pressure against it. They do wear out even under normal conditions. I’m on my second.

So what to do.

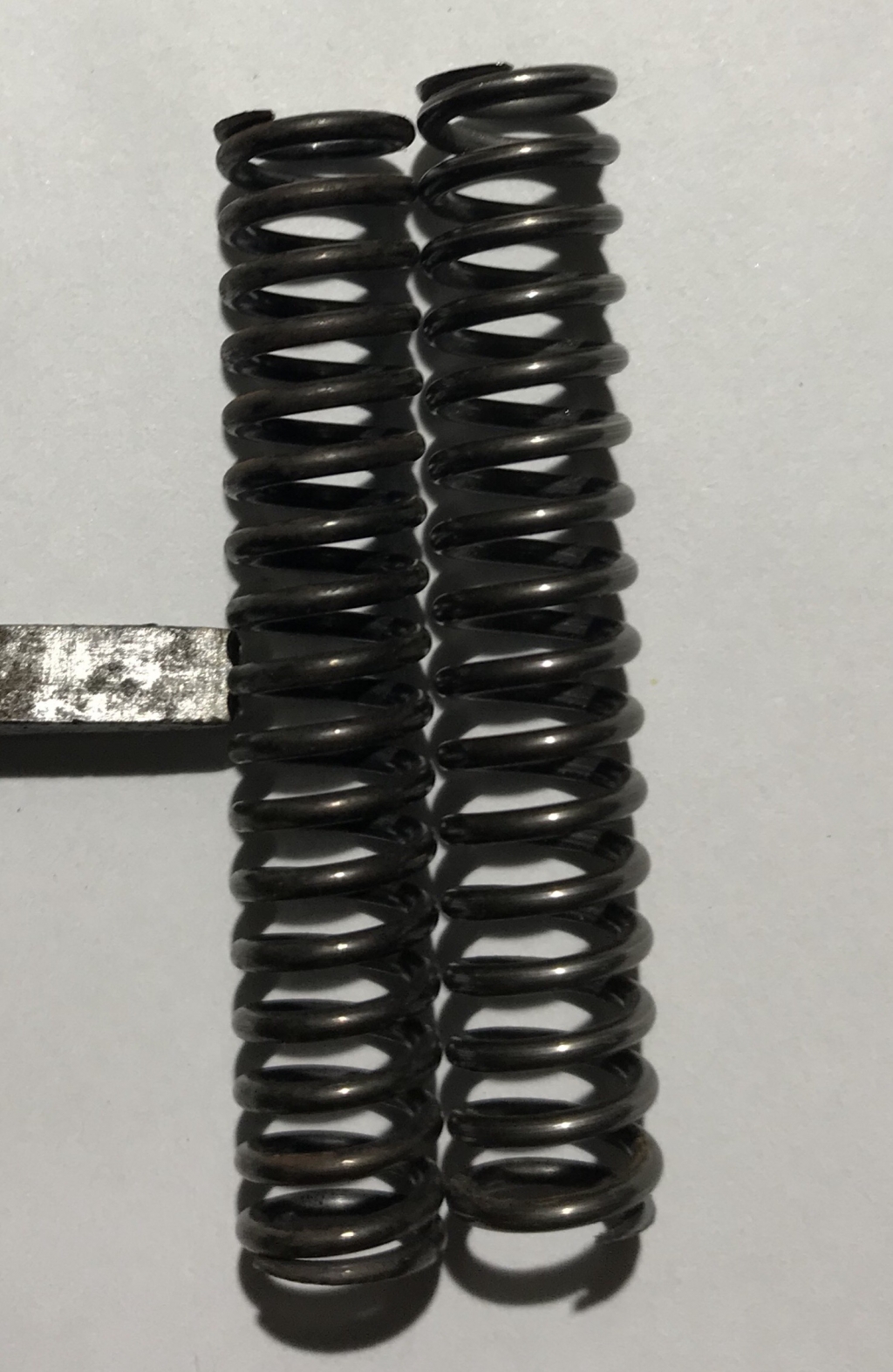

I was looking very closely at the new and old springs side by side and they are slightly different. The new spring has slightly more coils per inch. The more coils a spring has the softer it is. I know to a lot of people this doesn’t make sense but it a fact. Also a shorter spring is stiffer than a long spring all things equal again a fact. So my guess is fx where tying to match the spring rate of the old longer spring with a shorter spring and that’s why it has slightly more coils.

So what Ive done to get a higher spring rate and regain the use of my power wheel is cut the original spring to the shorter length.

Here they are side by side. In the second photo I have lined up the coils as accurately as possible. As you go down the spring you can see the coils start to stagger because the old spring has less coils per inch. (Stiffer)

I’ve just got the gun back together. It’s late here in Oz so I’ll test it tomorrow. Adjustment of the power wheel are now as they where with the old set up.

I couldn’t see a down side in trying this as even with a higher spring rate I can still adjust it down with my power wheel and I’m only going to be shooting slugs or RD monsters.

So Im hoping can get 970fps with my 26g slugs at 125bar as before but have normal adjustment on the power wheel.

Oh and Realisation You can no longer dry fire the gun to empty the plenum with the valve adjuster off.......

You can no longer dry fire the gun to empty the plenum with the valve adjuster off.......

Installing my kit I was unsure as to whether to use the original HS or the new shorter one supplied with the kit. . I had seen a few post from people not happy with the power they achieved with the new spring so I decided to go with my old longer spring.

With the old spring I had plenty of power (.22cal 26g slugs @ 970fps/ 125b)but also consistent pretension on the power wheel. Even on minimum with the adjuster screw backed out I couldn’t get any free play on the slider. It wasn’t tight but as soon as you started turning the power wheel it got tight after 1 or 2 clicks.

There are a couple of issues with it set up this way. 1 you lose your free floating hammer and 2 you have excessive wear on your power wheel. You don’t want to turn it with back pressure against it. They do wear out even under normal conditions. I’m on my second.

So what to do.

I was looking very closely at the new and old springs side by side and they are slightly different. The new spring has slightly more coils per inch. The more coils a spring has the softer it is. I know to a lot of people this doesn’t make sense but it a fact. Also a shorter spring is stiffer than a long spring all things equal again a fact. So my guess is fx where tying to match the spring rate of the old longer spring with a shorter spring and that’s why it has slightly more coils.

So what Ive done to get a higher spring rate and regain the use of my power wheel is cut the original spring to the shorter length.

Here they are side by side. In the second photo I have lined up the coils as accurately as possible. As you go down the spring you can see the coils start to stagger because the old spring has less coils per inch. (Stiffer)

I’ve just got the gun back together. It’s late here in Oz so I’ll test it tomorrow. Adjustment of the power wheel are now as they where with the old set up.

I couldn’t see a down side in trying this as even with a higher spring rate I can still adjust it down with my power wheel and I’m only going to be shooting slugs or RD monsters.

So Im hoping can get 970fps with my 26g slugs at 125bar as before but have normal adjustment on the power wheel.

Oh and Realisation