Well, now that I have had my first cup of coffee I have verified that my remaining M3 also has the hidden grub screws in the base of those holes - although a 1.5mm hex key seemed to be a really sloppy fit into them.

Boy, it sure would be nice if FX-USA chose to respond to this thread to provide some insight from the manufacturer's perspective.

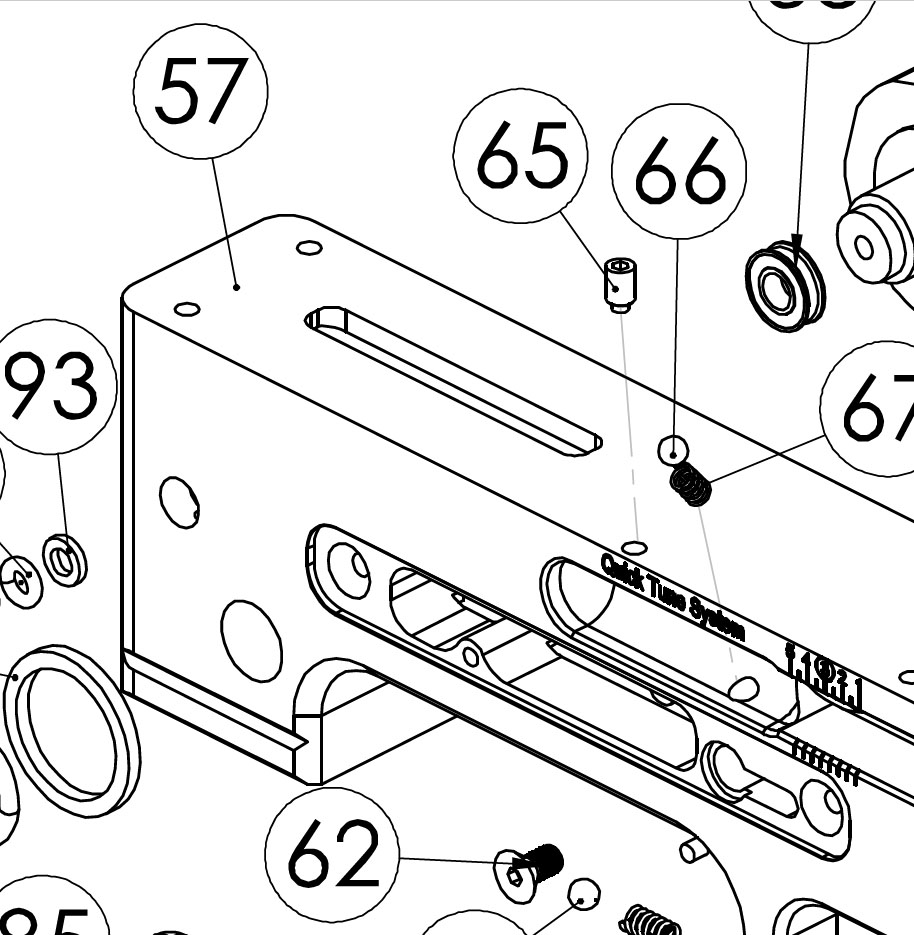

Once again, from my non-engineering background and education, it almost appears to me that the 2 threaded holes on the top of the block (in the area marked with the 57 bubble) line up with the holes in the bottom of the block, one of which was leaking in bconlon 's gun. I wonder whether, for production efficiencies, these holes are drilled completely through the block, with the intent of using the hidden grub screws with a pressure sealing thread adhesive to maintain pressure integrity. Or whether they are truly being used to deal with an F' up in the design or on the manufacturing line?

Boy, it sure would be nice if FX-USA chose to respond to this thread to provide some insight from the manufacturer's perspective.

Once again, from my non-engineering background and education, it almost appears to me that the 2 threaded holes on the top of the block (in the area marked with the 57 bubble) line up with the holes in the bottom of the block, one of which was leaking in bconlon 's gun. I wonder whether, for production efficiencies, these holes are drilled completely through the block, with the intent of using the hidden grub screws with a pressure sealing thread adhesive to maintain pressure integrity. Or whether they are truly being used to deal with an F' up in the design or on the manufacturing line?

Upvote 0