Hey Y'all!

I received my Revere about a week ago and have been spending some time getting to know it when I'm home from work. It's a keeper! Even more than a keeper, I can tell it's going to become one of my favorites (if not my #1).

Like all my rifles, it needed a picatinny rail for the bipod.

Today was the day for drilling into that beautiful stock! Here's a peek at the revere with the stock off...

For this install, I decided on the BT34 rail from Atlas. While I love Accu-Tac for bipods, I like Atlas for rails.

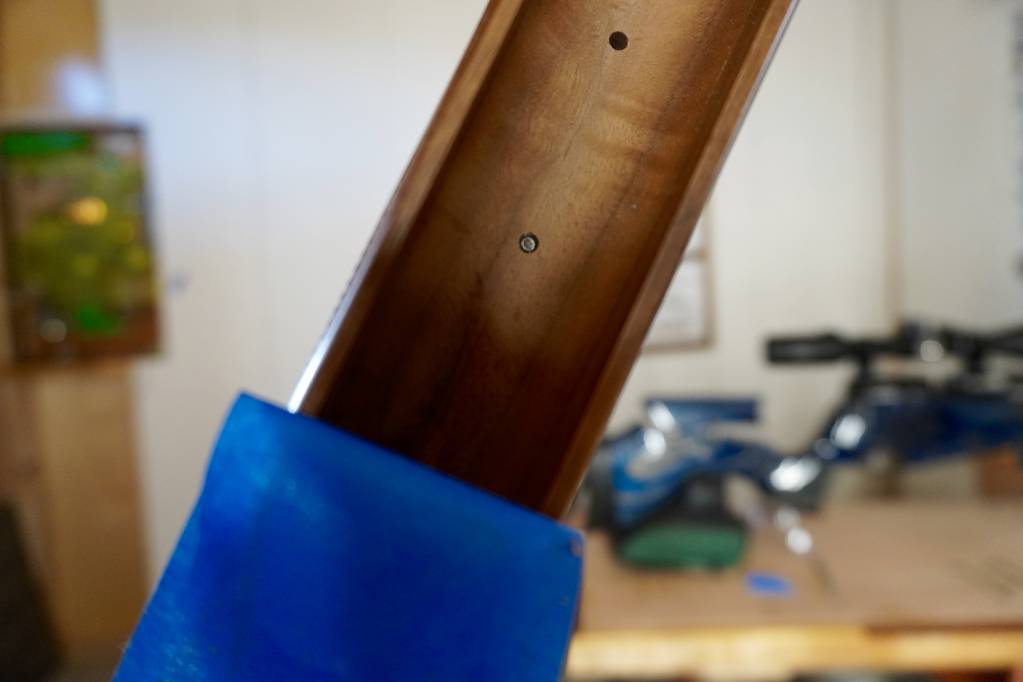

I started out by putting some blue painters tape on the stock in order to protect the finish and then marked the locations for the holes, front and back..

Next up was finding the center line. I couldn't find my center finder tool so, I went old school and grabbed a set of combination squares. Back and forth I went until I found dead center. (It's right around 7/8" if you're planning on doing this to yours.)

Now that I had crosshairs on the holes, it was time to center punch and drill some pilot holes. I drill the small pilot holes all the way through in order to give myself a perpendicular landmark on the inside of the stock. That way, I know I'm in the right spot and can tell if I'm drilling straight.

The drill bit looks big in this pic, for some reason. It wasn't though. Pilot holes are normally very small.

Many Daystate rifles come with incredibly thin stocks (Red Wolf, Wolverine) and T-nuts may be too thick to be used. This is that point where you need to make a decision on what type of fasteners you want to use. But, how can you tell the true thickness when the stock is so curvy?

Here's a quick and easy idea to tell how thick of material you're working with... After you drill the pilot holes, stick the base of the drill bit back into the hole until it's flush with the inside. Mark it with a Sharpie and take it back out. Bingo! Instant depth gauge!

Next up is drilling with the paddle bit. This is where things can get intimidating. I could have made a jig to hold the oddly shaped stock perfectly level but, I decided to "wing it" for this one. I laid a couple levels on the stock and got to drilling. I rolled up a towel in order to lay the stock on. I knew there was a remote chance that it could get caught up in the drill but, I had no plans on going all the way through. It allowed me to adjust the stock as needed to keep it squared up and protected the finish.

This part sucks so, take your time with it. It's better to take little bites at a time rather than possibly go too deep and cause some other headaches.

Once the paddle bit hole is deep enough to allow for a flush fit of the T-nuts, it's time to drill all the way through with a 1/4 drill bit. This is where that pilot hole can come in handy. You can flip the stock over and drill right on through. I had everything set up already from the paddle bit so, I just went for it from the inside of the stock. It's a risky short cut but, I felt confident.

A quick test install revealed the difference in depths I would be working with. I would have to cut down one of the screws so that it wouldn't hit the air tube. The bench grinder made quick work of it. I also hammered the teeth on the T-nuts flat. If I was working with thicker and softer material, I'd leave them alone. They work fine like this. You just have to press on them when you run the screws in.

The test install also showed me that I was a bit crooked. Probably from when I used that short cut to drill the 1/4" holes. I grabbed a wood file and moved the holes ever so slightly.

Presto! Bada Bing! A new rail is installed! I like how thin and small the BT34 is for a rifle like this. It doesn't stick out too much and take away from the beauty of the rifle.

If it's your first time taking on a project like this, just take your time and measure twice!

Happy Shooting!

Tomcat

I received my Revere about a week ago and have been spending some time getting to know it when I'm home from work. It's a keeper! Even more than a keeper, I can tell it's going to become one of my favorites (if not my #1).

Like all my rifles, it needed a picatinny rail for the bipod.

Today was the day for drilling into that beautiful stock! Here's a peek at the revere with the stock off...

For this install, I decided on the BT34 rail from Atlas. While I love Accu-Tac for bipods, I like Atlas for rails.

I started out by putting some blue painters tape on the stock in order to protect the finish and then marked the locations for the holes, front and back..

Next up was finding the center line. I couldn't find my center finder tool so, I went old school and grabbed a set of combination squares. Back and forth I went until I found dead center. (It's right around 7/8" if you're planning on doing this to yours.)

Now that I had crosshairs on the holes, it was time to center punch and drill some pilot holes. I drill the small pilot holes all the way through in order to give myself a perpendicular landmark on the inside of the stock. That way, I know I'm in the right spot and can tell if I'm drilling straight.

The drill bit looks big in this pic, for some reason. It wasn't though. Pilot holes are normally very small.

Many Daystate rifles come with incredibly thin stocks (Red Wolf, Wolverine) and T-nuts may be too thick to be used. This is that point where you need to make a decision on what type of fasteners you want to use. But, how can you tell the true thickness when the stock is so curvy?

Here's a quick and easy idea to tell how thick of material you're working with... After you drill the pilot holes, stick the base of the drill bit back into the hole until it's flush with the inside. Mark it with a Sharpie and take it back out. Bingo! Instant depth gauge!

Next up is drilling with the paddle bit. This is where things can get intimidating. I could have made a jig to hold the oddly shaped stock perfectly level but, I decided to "wing it" for this one. I laid a couple levels on the stock and got to drilling. I rolled up a towel in order to lay the stock on. I knew there was a remote chance that it could get caught up in the drill but, I had no plans on going all the way through. It allowed me to adjust the stock as needed to keep it squared up and protected the finish.

This part sucks so, take your time with it. It's better to take little bites at a time rather than possibly go too deep and cause some other headaches.

Once the paddle bit hole is deep enough to allow for a flush fit of the T-nuts, it's time to drill all the way through with a 1/4 drill bit. This is where that pilot hole can come in handy. You can flip the stock over and drill right on through. I had everything set up already from the paddle bit so, I just went for it from the inside of the stock. It's a risky short cut but, I felt confident.

A quick test install revealed the difference in depths I would be working with. I would have to cut down one of the screws so that it wouldn't hit the air tube. The bench grinder made quick work of it. I also hammered the teeth on the T-nuts flat. If I was working with thicker and softer material, I'd leave them alone. They work fine like this. You just have to press on them when you run the screws in.

The test install also showed me that I was a bit crooked. Probably from when I used that short cut to drill the 1/4" holes. I grabbed a wood file and moved the holes ever so slightly.

Presto! Bada Bing! A new rail is installed! I like how thin and small the BT34 is for a rifle like this. It doesn't stick out too much and take away from the beauty of the rifle.

If it's your first time taking on a project like this, just take your time and measure twice!

Happy Shooting!

Tomcat