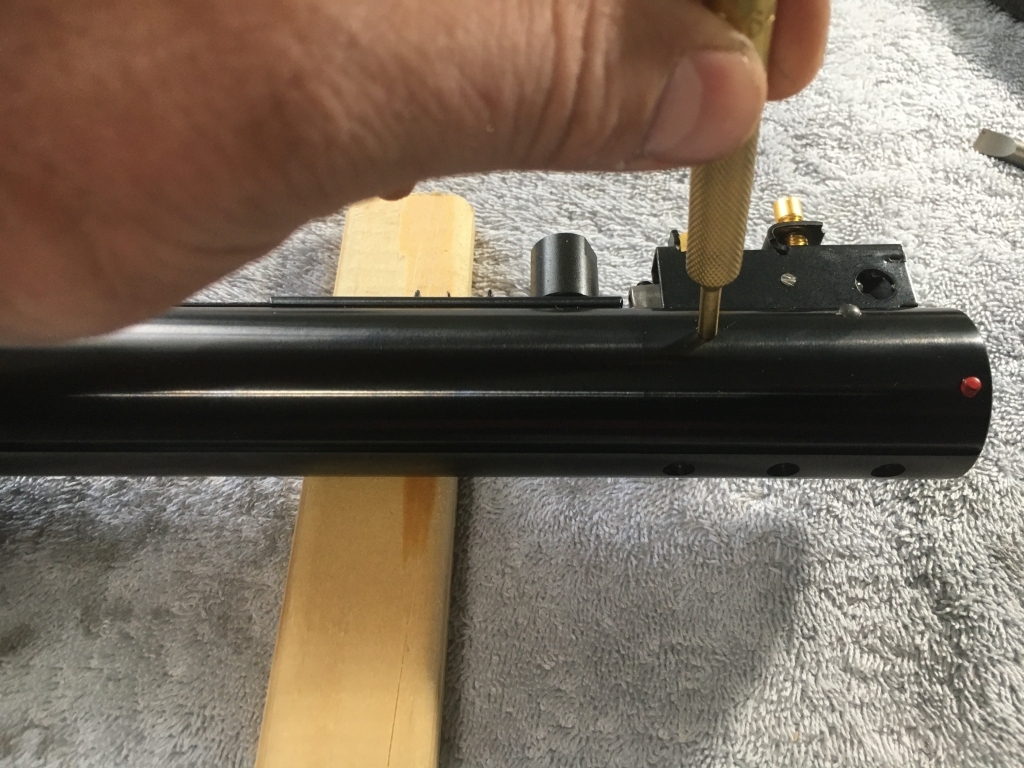

And boy did it need it! It's a rainy day today, so I decided to take a brand new HW97K of mine and tear it down for a good cleaning, polishing and inspection. The rifle has never been used and I am wanting to start shooting it. I bought it new from Krale a year ago. It was taken out of the box, wiped down good with an oily rag and placed in the safe. I don't think I have ever seen a new rifle this dirty and cruddy. This is why I take them down new before I really run them. This is gonna be really pic heavy. But I thought I would share....some may find it interesting.

I have spent a solid two hours thus far doing nothing but cleaning. The grease that was used during the assembly has to be the thickest, stickiest nastiest grease I have ever seen. The only thing that I can compare it to is the Cosmoline that old military arms were packed in for long term storage. The degreasing took FOREVER.....I am finally getting there though. The Q-tips are starting to come clean. There were also areas where the grease had dried and became crusty. The threads on the trigger block were horrendous as you can see in the pic. They are now clean as well. I have a new piston seal that I had ordered before I started this. It is supposed to arrive tomorrow afternoon. I kinda had a feeling that I may want a new seal after getting into this. Looking at the factory seal.....I am glad I ordered one. A little more cleaning and then beginning the process of polishing some parts this evening. Once I get the new piston seal, I'll re-lube everything properly to my liking, and should be mounting the scope and shooting New Years day I hope.

TR

I have spent a solid two hours thus far doing nothing but cleaning. The grease that was used during the assembly has to be the thickest, stickiest nastiest grease I have ever seen. The only thing that I can compare it to is the Cosmoline that old military arms were packed in for long term storage. The degreasing took FOREVER.....I am finally getting there though. The Q-tips are starting to come clean. There were also areas where the grease had dried and became crusty. The threads on the trigger block were horrendous as you can see in the pic. They are now clean as well. I have a new piston seal that I had ordered before I started this. It is supposed to arrive tomorrow afternoon. I kinda had a feeling that I may want a new seal after getting into this. Looking at the factory seal.....I am glad I ordered one. A little more cleaning and then beginning the process of polishing some parts this evening. Once I get the new piston seal, I'll re-lube everything properly to my liking, and should be mounting the scope and shooting New Years day I hope.

TR