I hit the 13,500 shots fired mark the other day with my 80. The mainspring was buzzing so I decided it was time for another cleaning and spring lube. Upon removing the stock I felt that the screw yoke had loosened up. The allen wrench simply removed the already broken off screw head. The fine thread stud was frozen in place with thread lock compound. My smallest EZ out tool was too big for this job. I drilled deep and drove in a hex drive bit. Slow and steady twisting and it came out. I ended up placing an order for the screw (3) and numerous other 80 parts with TW Chambers. A $2.30 screw turned into an $80.00 order.

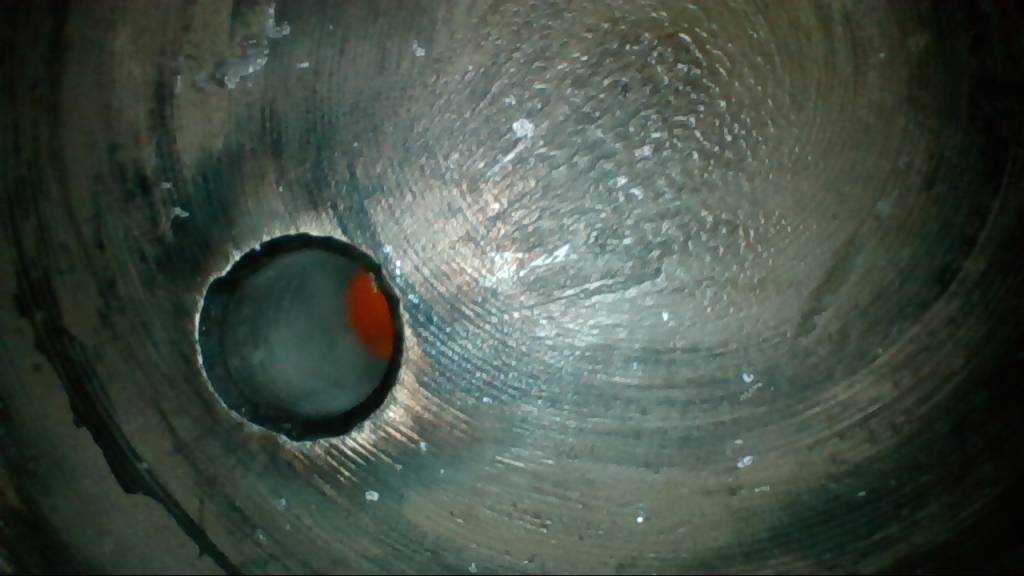

At this point I decided to do a complete tear down and servicing. The Vortek piston seal was showing melting of the face just like the previous seal. It was not torn and will be reused when my parts arrive. I took a look inside the compression chamber with one of my Teslong bore scopes. Lots of evidence seen from the extreme heat generated at compression. Carbon deposits all over at the end of the chamber walls. You can see where super heated melted molecules of seal plastic have adhered to the chamber end wall. You can also see the flow pattern of the melted plastic going towards the TP hole.

The other issue I have, despite frequent lubrication, is that the cocking link strut is loose at the rivet pin. Has the feel of about .020 slop at the pin. I ordered one of those Harbor Freight chain breaking tools to drive the pin out. I will use the opposing ball bearing and vise method of swaging the new pin in place. I have a new cocking lever rod coming, in case the rivet pin hole has opened up.

Who here has done the rivet pin replacement? Can I expect the pin to be worn down or the hole in the link to be opened up from wear?

The wear pattern on the tube tells me this yoke was loose and hammering the tube for sometime.

New Vortek seal on left, right is other previous Vortek seal with 8500 shots on it.

The Teslong pictures are approximately 30X magnified. Looks worse than it really is. I will make no attempt to clean this condition. The first photo shows the smooth bore surface just ahead of the deposits.

Oh yeah, notice the butt pad wear pattern from my blue jeans when cocking. Might need another one someday.

At this point I decided to do a complete tear down and servicing. The Vortek piston seal was showing melting of the face just like the previous seal. It was not torn and will be reused when my parts arrive. I took a look inside the compression chamber with one of my Teslong bore scopes. Lots of evidence seen from the extreme heat generated at compression. Carbon deposits all over at the end of the chamber walls. You can see where super heated melted molecules of seal plastic have adhered to the chamber end wall. You can also see the flow pattern of the melted plastic going towards the TP hole.

The other issue I have, despite frequent lubrication, is that the cocking link strut is loose at the rivet pin. Has the feel of about .020 slop at the pin. I ordered one of those Harbor Freight chain breaking tools to drive the pin out. I will use the opposing ball bearing and vise method of swaging the new pin in place. I have a new cocking lever rod coming, in case the rivet pin hole has opened up.

Who here has done the rivet pin replacement? Can I expect the pin to be worn down or the hole in the link to be opened up from wear?

The wear pattern on the tube tells me this yoke was loose and hammering the tube for sometime.

New Vortek seal on left, right is other previous Vortek seal with 8500 shots on it.

The Teslong pictures are approximately 30X magnified. Looks worse than it really is. I will make no attempt to clean this condition. The first photo shows the smooth bore surface just ahead of the deposits.

Oh yeah, notice the butt pad wear pattern from my blue jeans when cocking. Might need another one someday.