RiverDevil:

I am having a hard time following your points. Are you implying that the K1 has grooves in the magazine that locates to the barrel?

from the beginning I got the gun for close in use and high energy combined with the internal silencer. That is why it is primarily mounted with only a 3X optic.

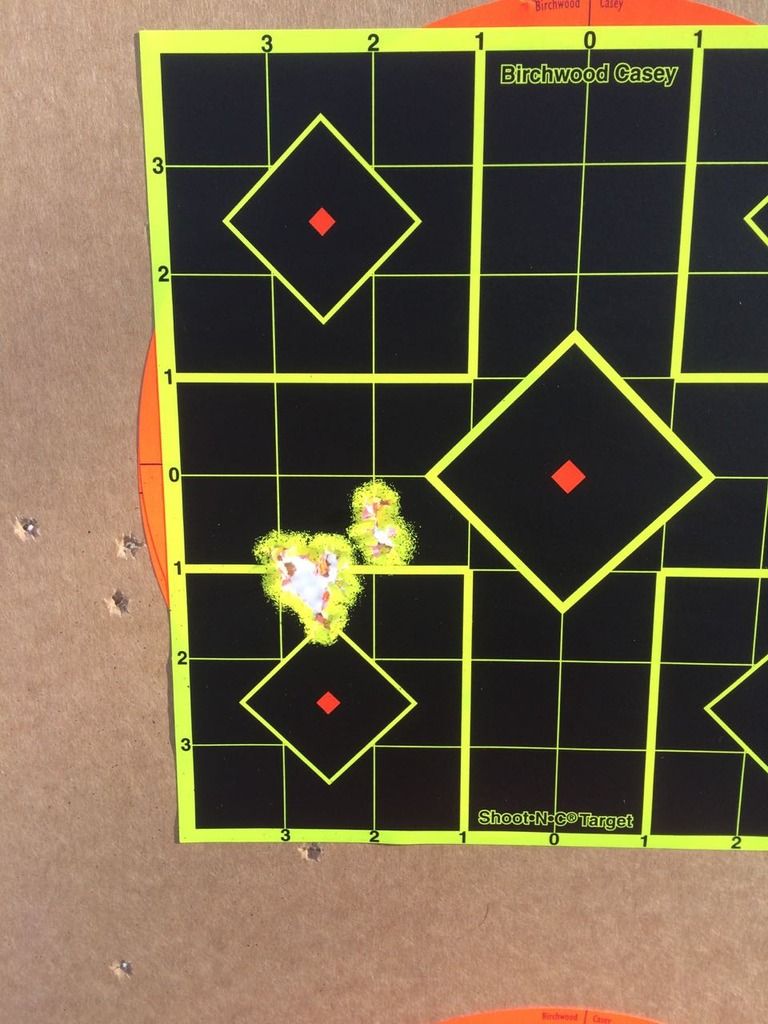

The K1 shoots dead on at 50 yards and has the potential energy of a .22 LR. For me and my use it exceeds my expectations and has replaced my rimfire guns. If I want to reach out to 150 yards I will get my .17 rimfire not an air gun.

High shot count, high energy and low noise, not to mention the ability to turn a knob and make the round go super sonic make this gun a no brainier for me.

added bonus is semi auto operation and easy to load high capacity mag.

from the beginning I stated that I was not a shooter of air guns like Ted, my goals were different and this gun is outstanding for what I use it for.

the quest for "long range" shooting is just to see if can be done. With that said within 50 yards this gun is deadly

sent from IPhone5

I am having a hard time following your points. Are you implying that the K1 has grooves in the magazine that locates to the barrel?

from the beginning I got the gun for close in use and high energy combined with the internal silencer. That is why it is primarily mounted with only a 3X optic.

The K1 shoots dead on at 50 yards and has the potential energy of a .22 LR. For me and my use it exceeds my expectations and has replaced my rimfire guns. If I want to reach out to 150 yards I will get my .17 rimfire not an air gun.

High shot count, high energy and low noise, not to mention the ability to turn a knob and make the round go super sonic make this gun a no brainier for me.

added bonus is semi auto operation and easy to load high capacity mag.

from the beginning I stated that I was not a shooter of air guns like Ted, my goals were different and this gun is outstanding for what I use it for.

the quest for "long range" shooting is just to see if can be done. With that said within 50 yards this gun is deadly

sent from IPhone5

Upvote 0