You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to stop trashing vs seals

- Thread starter biohazardman

- Start date

Use silicone lube/grease. No need to freeze or whatever ur doing to it. Make sure the valve seat is placed evenly before applying pressure to fit it in its place. If the valve seat oring is causing resistance use a small pick that’s rounded (not sharp) to push the oring in while pushing the valve seat in place. You might have to push all around the oring to get it in. It’ll also be easier if u take off the lower bridge so u can have access to use ur rounded pick to push the oring in place. The oring should be 1.5mm x 7mm nbr70

Upvote 0

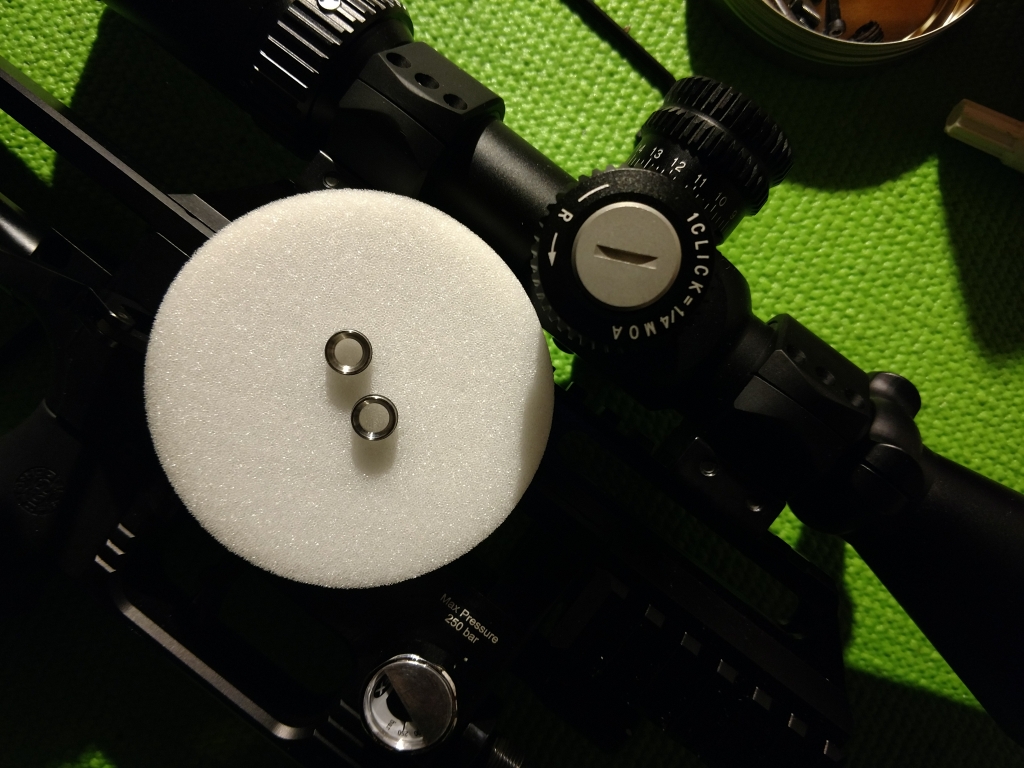

Grind an angle on those three edges and polish them. You can see the angle on mine at the bottom of the housing in this pic.

Upvote 0

I put the thing in the freezer to gain a thousandth or two as the metal will actually shrink up. Not nearly what I need though. I used the grease and a blunt object to push in the o-ring as well. I didn't cut the bridge off cuz I just wanted a little bit more power for my .25 not a bunch and not going to .30. I wonder how FX does it cuz they don't cut the bridge. Still if I can't get it any other way that is what I will do.

Thank you both

Thank you both

Upvote 0

You can still use the pick method without removing the bridge. Main thing is plenty of lube on the entrance of the valve housing as well as the VS oring. Once the VS is placed correctly use a tool to push it in evenly till the oring of the VS makes contact. While applying pressure to seat the VS with the tool, use the pick in between the bridges to push the oring in. That should work. If not then I’m guessing the VS groove isn’t deep enough for the oring to fit properly and is sticking out more then it should.

Upvote 0

If that is a larger vs, the oring is probably 7x1 and no 7x1.5 if you use a larger 7*1.5 oring will be hard to fit (if fits) and will probably slice no matter what.

No need to cut anything.

https://www.instagram.com/p/BxNDehxBt62/?igshid=wh7asqov5d6f

No need to cut anything.

https://www.instagram.com/p/BxNDehxBt62/?igshid=wh7asqov5d6f

Upvote 0

edosan

The replacement vs is 6.25mm but when I measured the o-ring slot ID it was the same so I just figured it took the same size o-ring. But as it turns out the width of the o-ring slot is much narrower, and plain to see if I was looking, so your assessment is probly correct. That vid makes me feel really bad after putting a couple of hours into trying to do that over and over again and just chopping up o-ring after o-ring no matter how I did it. It's like the perfect description of insanity doing the same thing over and over and expecting a different end result.

after putting a couple of hours into trying to do that over and over again and just chopping up o-ring after o-ring no matter how I did it. It's like the perfect description of insanity doing the same thing over and over and expecting a different end result. But the doctors told me I have brain damage so at least I have an excuse. Looks like I will be paying another visit to the seal shop for some different o-rings. Funny thing is I tried to buy a smaller o-ring so I could stretch it and make it thinner if I needed to but they did not have the size. Thanks for stopping the insanity it was making me crazy.

But the doctors told me I have brain damage so at least I have an excuse. Looks like I will be paying another visit to the seal shop for some different o-rings. Funny thing is I tried to buy a smaller o-ring so I could stretch it and make it thinner if I needed to but they did not have the size. Thanks for stopping the insanity it was making me crazy.

The replacement vs is 6.25mm but when I measured the o-ring slot ID it was the same so I just figured it took the same size o-ring. But as it turns out the width of the o-ring slot is much narrower, and plain to see if I was looking, so your assessment is probly correct. That vid makes me feel really bad

Upvote 0

you are getting crazy for like 3 bucks!

http://www.oringsandmore.com/metric-buna-o-rings-7-x-1mm-price-for-50-pcs/

http://www.oringsandmore.com/metric-buna-o-rings-7-x-1-2mm-price-for-25-pcs/

for me is just that (looks like). Good luck!

That works sometimes, but temporary, too stretch might result in a broken o'ring sooner or later

http://www.oringsandmore.com/metric-buna-o-rings-7-x-1mm-price-for-50-pcs/

http://www.oringsandmore.com/metric-buna-o-rings-7-x-1-2mm-price-for-25-pcs/

for me is just that (looks like). Good luck!

Funny thing is I tried to buy a smaller o-ring so I could stretch it and make it thinner if I needed to but they did not have the size.

That works sometimes, but temporary, too stretch might result in a broken o'ring sooner or later

Upvote 0

Thanks for that they cost me $.50 each at the seal store, two miles down the road, with a $10 minimum but I can have them now if they have them that is. The addiction says I got to have them now so I can shoot my Impact. I'm going through withdrawals here haven't shot in two days. ;^) If they don't have them then your links will be used and I will have to shudder and shake and be feverish until they get here.

Upvote 0

No problem!

Suggestion: for us$50 +- you can get all the orings for life for your impact, check schematics on FX page , almost all o'rings are listed there.

Better to have all for that price ...

Suggestion: for us$50 +- you can get all the orings for life for your impact, check schematics on FX page , almost all o'rings are listed there.

Better to have all for that price ...

Upvote 0

buy a hand full of different sizes for next time

https://www.theoringstore.com/store/index.php?main_page=index&cPath=368_12

https://www.theoringstore.com/store/index.php?main_page=index&cPath=368_12

Upvote 0

Well picked up some 7x1mm o-rings and they did not fit but at least I have 60 of them. ;^). I measured the o-ring slot the depth is perfect but the width is 1.40mm the original is 1.60mm wide so that's why the o-rings don't fit. Grrr... Looks like more garbage from eBay. Maybe I can stretch a 6x1.5mm to fit? Or drill out my stock vs to? and be done with it? If not I will need a new one from elsewhere.

Looks like more garbage from eBay. Maybe I can stretch a 6x1.5mm to fit? Or drill out my stock vs to? and be done with it? If not I will need a new one from elsewhere.

So I ended up drilling my stock VS out to a letter B drill which is 6.10mm and put it back in. After all that drama and $ spent on no good VS parts and O-rings, I will probly never use, the gun is back together with no leaks. I will have to see what the chrony says to know if all this was worth the trouble but my guess is it was.

So I ended up drilling my stock VS out to a letter B drill which is 6.10mm and put it back in. After all that drama and $ spent on no good VS parts and O-rings, I will probly never use, the gun is back together with no leaks. I will have to see what the chrony says to know if all this was worth the trouble but my guess is it was.

Upvote 0

buy a hand full of different sizes for next time

https://www.theoringstore.com/store/index.php?main_page=index&cPath=368_12

Yup I need a metric assortment pack but have not found one that has the sizes I like. So like you said I need to make my own. Need a metric drill bit set too one of these days.

Upvote 0

"So I ended up drilling my stock VS out to a letter B drill which is 6.10mm and put it back in."

Big difference between these two holes! 6mm and 6.5mm. I used a hand drill to spin the valve seat while I used chainsaw file to open up the hole to the size I wanted. Also polished the sharp inside edges so the valve seal didn't eat into the valve seat.

Upvote 0

Nice job on the cave man machining I have done a fair amount of that myself. ;^) Yes, I could have opened it up more but it is shooting the .25 36gr Nielsen slugs at over 980fps even without the hammer being adjusted up tight. Since I don't have plans to go to .30cal I doubt I will need to open it up any further for my needs. Still after all I just went through I knows how to do it if I want more.

Upvote 0

Well picked up some 7x1mm o-rings and they did not fit but at least I have 60 of them. ;^). I measured the o-ring slot the depth is perfect but the width is 1.40mm the original is 1.60mm wide so that's why the o-rings don't fit. Grrr...Looks like more garbage from eBay. Maybe I can stretch a 6x1.5mm to fit? Or drill out my stock vs to? and be done with it? If not I will need a new one from elsewhere.

So I ended up drilling my stock VS out to a letter B drill which is 6.10mm and put it back in. After all that drama and $ spent on no good VS parts and O-rings, I will probly never use, the gun is back together with no leaks. I will have to see what the chrony says to know if all this was worth the trouble but my guess is it was.

You need to find the correct oring, that´s all. 7*1 do not make a seal?, if is too deep try more combinations is just about to find the right oring ... try O-ring 6,35 x 1,27 NBR 70 that has worked fine when the groove is a bit deep. Or get several sizes. oringsandmore o theoringstore is a very simple thing really.

Upvote 0

If you do get a assorted kit,dont get the cheap Amazon ,ebay ones as they are just standard orings cross referenced...kelly

Upvote 0

Well picked up some 7x1mm o-rings and they did not fit but at least I have 60 of them. ;^). I measured the o-ring slot the depth is perfect but the width is 1.40mm the original is 1.60mm wide so that's why the o-rings don't fit. Grrr...Looks like more garbage from eBay. Maybe I can stretch a 6x1.5mm to fit? Or drill out my stock vs to? and be done with it? If not I will need a new one from elsewhere.

So I ended up drilling my stock VS out to a letter B drill which is 6.10mm and put it back in. After all that drama and $ spent on no good VS parts and O-rings, I will probly never use, the gun is back together with no leaks. I will have to see what the chrony says to know if all this was worth the trouble but my guess is it was.

You need to find the correct oring, that´s all. 7*1 do not make a seal?, if is too deep try more combinations is just about to find the right oring ... try O-ring 6,35 x 1,27 NBR 70 that has worked fine when the groove is a bit deep. Or get several sizes. oringsandmore o theoringstore is a very simple thing really.

Figured that I could find the right o-ring with enough werq but I drilled the stock VS cuz I could. ;^) I will find the correct o-ring for the 6.25mm VS I have left. The stock VS went back in so easy with a new o-ring!!

Upvote 0