Can anyone out there tell me the correct way to remove the air valve in the receiver of an HM1000X rifle to clean, replace o-rings etc.? Thank you.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HM1000X valve removal

- Thread starter hotair

- Start date

https://www.jimmiedeesairguns.com/guides/service-guides/theoben-rapid-mkii-service-guide/a-service-guide-for-the-theoben-rapid-mkii/

This is for Theoben Rapid which is essentially the same gun.

This is for Theoben Rapid which is essentially the same gun.

Upvote 0

DO NOT attempt to disassemble anything unless theres a problem with the gun.

So assuming you have valve failure that forces a disassembly you make it easy by removing the top forward barrel set screw top scope rail forward the magazine and the big hex on the cocking lever side barrel tensioner Allen screw and slide the barrel out.

Remove the bottle and burp it by cocking and firing as you unscrew to not damage the bottle oring. Unscrew the V block.

Remove that small set screw located at the 5 oclock position in relation to the magazine. Unscrew the stainless steel Valve plate in between barrel and V Block thats left.

Point the gun down and cock and fire then the Valve should come right out.

So assuming you have valve failure that forces a disassembly you make it easy by removing the top forward barrel set screw top scope rail forward the magazine and the big hex on the cocking lever side barrel tensioner Allen screw and slide the barrel out.

Remove the bottle and burp it by cocking and firing as you unscrew to not damage the bottle oring. Unscrew the V block.

Remove that small set screw located at the 5 oclock position in relation to the magazine. Unscrew the stainless steel Valve plate in between barrel and V Block thats left.

Point the gun down and cock and fire then the Valve should come right out.

Upvote 0

Point the gun down and cock and fire then the Valve should come right out.

please ! Don’t do this, there is the very real possibility the hammer will over ride the trigger sear and smash into the cocking pin causing it to bend/dent, this will then be a bu99er to remove and will need replacing.

Much safer option, once the valve cap and location screw are removed....undo the hammer cap, pull out the spring and inertia weight taking note of orientation, knock out the two location pins in the side of the block and the trigger cassette will drop straight out. This will allow the hammer to fall out the back of the block. now with a 6mm wooden or delrin dowel , you can push the valve out via the hammer channel.

Bb

Upvote 0

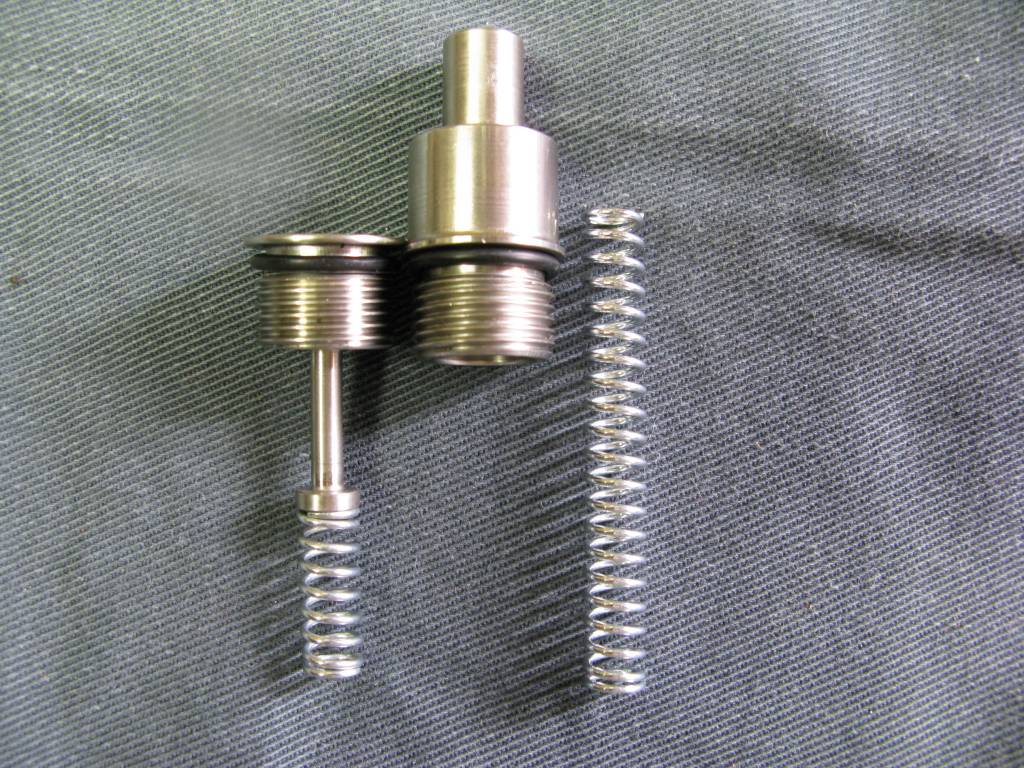

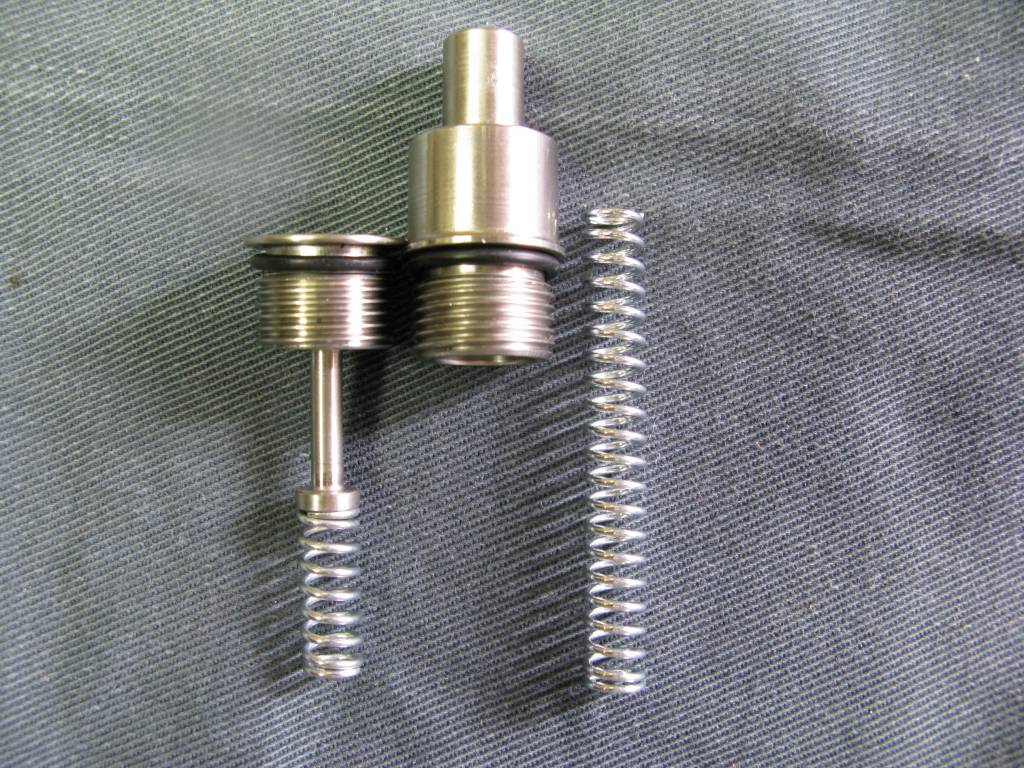

Thank you for the input. I had read an article about using the 'firing' method to remove the valve and it did jam things up real good. The bucketboy method sounds right to me. One reason I asked how to remove the valve is to understand how the valving works. I had another post on how to get more power from my .25 cal. RAW. I've since gotten the Huma reg. and a small front mounting external plenum. When the Huma reg. was put in there was no change in fps. with the hammer and reg. settings being the same. The reg. for both stock and Huma is 150bar. The velocity for both was 915fps with the JSB 34's. I was expecting something to change but nothing did. By putting the Huma reg. in more plenum space was gained.  A friend replaced the stock reg. with the Huma in .22 cal. and said he got an increase in velocity of 10% with no other changes. Why did I get nothing? When I got the external plenum from Martin there wasn't any type of stop in the end. Only the longer spring. Which is pretty stiff making the valve harder to open than necessary. See pics.

A friend replaced the stock reg. with the Huma in .22 cal. and said he got an increase in velocity of 10% with no other changes. Why did I get nothing? When I got the external plenum from Martin there wasn't any type of stop in the end. Only the longer spring. Which is pretty stiff making the valve harder to open than necessary. See pics. Having already put a much lighter spring in my Impact with a stop so the valve rod couldn't come out of the valve body at the breech end and the valve opening could be regulated with the valve adjustment knob at the front of the receiver. A gain of 40fps was made. With the FX gun less valve spring translated to less hammer spring which translated in using the same hammer spring with higher reg. pressures without having to use a stronger hammer spring and or hammer weight to get the same and higher power. So I was looking to do the same with the RAW. But with no stop and a lighter valve spring what's stopping the valve from trying to come out towards the front of the gun therefore opening beyond what is necessary and possibly damaging the valve etc.? It looks like a stop needs to be put in to limit the valve opening when using a lighter spring. With the Impact a valve opening of .150'' was all that was necessary to get the 40fps gain. With some projectiles an opening of .100'' got the same velocity. Opening it to .200'' did nothing with the pressure used in the reg. which was 135bar. Question: How far should the valve open for max power? I realize that the stock RAW HM1000X doesn't have the adjustments that the Impact has. I was thinking that with the Huma reg. and the external plenum a gain of 50fps should be gained with not too much increase in reg. pressure. I was told the external plenum pictured should get me about a 30fps gain. I guess a lighter valve spring will be tried to see if it changes anything on the HM1000X.

Having already put a much lighter spring in my Impact with a stop so the valve rod couldn't come out of the valve body at the breech end and the valve opening could be regulated with the valve adjustment knob at the front of the receiver. A gain of 40fps was made. With the FX gun less valve spring translated to less hammer spring which translated in using the same hammer spring with higher reg. pressures without having to use a stronger hammer spring and or hammer weight to get the same and higher power. So I was looking to do the same with the RAW. But with no stop and a lighter valve spring what's stopping the valve from trying to come out towards the front of the gun therefore opening beyond what is necessary and possibly damaging the valve etc.? It looks like a stop needs to be put in to limit the valve opening when using a lighter spring. With the Impact a valve opening of .150'' was all that was necessary to get the 40fps gain. With some projectiles an opening of .100'' got the same velocity. Opening it to .200'' did nothing with the pressure used in the reg. which was 135bar. Question: How far should the valve open for max power? I realize that the stock RAW HM1000X doesn't have the adjustments that the Impact has. I was thinking that with the Huma reg. and the external plenum a gain of 50fps should be gained with not too much increase in reg. pressure. I was told the external plenum pictured should get me about a 30fps gain. I guess a lighter valve spring will be tried to see if it changes anything on the HM1000X.

Upvote 0

firstable you have to bleed air off the system.... take off the bottle and take a shot just to bleed the plenum air.... then you will have to loosen a screw located on the right side of the block (this one secures the valve)..... at this moment, the hammer will push the valve forward because of the tension, unscrew the valve retainer screw (this one is located under the barrel and above the regulator)...... when re-installing it, make sure you cock the rifle before pushing the valve back in place (this way you avoid to bend the valve)... remember also to cock the rifle before screwing the bottle (otherwise the air will come out thru the barrel because valve is open)

Upvote 0

Thank you for the input. I had read an article about using the 'firing' method to remove the valve and it did jam things up real good. The bucketboy method sounds right to me. One reason I asked how to remove the valve is to understand how the valving works. I had another post on how to get more power from my .25 cal. RAW. I've since gotten the Huma reg. and a small front mounting external plenum. When the Huma reg. was put in there was no change in fps. with the hammer and reg. settings being the same. The reg. for both stock and Huma is 150bar. The velocity for both was 915fps with the JSB 34's. I was expecting something to change but nothing did. By putting the Huma reg. in more plenum space was gained.A friend replaced the stock reg. with the Huma in .22 cal. and said he got an increase in velocity of 10% with no other changes. Why did I get nothing? When I got the external plenum from Martin there wasn't any type of stop in the end. Only the longer spring. Which is pretty stiff making the valve harder to open than necessary. See pics. Having already put a much lighter spring in my Impact with a stop so the valve rod couldn't come out of the valve body at the breech end and the valve opening could be regulated with the valve adjustment knob at the front of the receiver. A gain of 40fps was made. With the FX gun less valve spring translated to less hammer spring which translated in using the same hammer spring with higher reg. pressures without having to use a stronger hammer spring and or hammer weight to get the same and higher power. So I was looking to do the same with the RAW. But with no stop and a lighter valve spring what's stopping the valve from trying to come out towards the front of the gun therefore opening beyond what is necessary and possibly damaging the valve etc.? It looks like a stop needs to be put in to limit the valve opening when using a lighter spring. With the Impact a valve opening of .150'' was all that was necessary to get the 40fps gain. With some projectiles an opening of .100'' got the same velocity. Opening it to .200'' did nothing with the pressure used in the reg. which was 135bar. Question: How far should the valve open for max power? I realize that the stock RAW HM1000X doesn't have the adjustments that the Impact has. I was thinking that with the Huma reg. and the external plenum a gain of 50fps should be gained with not too much increase in reg. pressure. I was told the external plenum pictured should get me about a 30fps gain. I guess a lighter valve spring will be tried to see if it changes anything on the HM1000X.

Having already put a much lighter spring in my Impact with a stop so the valve rod couldn't come out of the valve body at the breech end and the valve opening could be regulated with the valve adjustment knob at the front of the receiver. A gain of 40fps was made. With the FX gun less valve spring translated to less hammer spring which translated in using the same hammer spring with higher reg. pressures without having to use a stronger hammer spring and or hammer weight to get the same and higher power. So I was looking to do the same with the RAW. But with no stop and a lighter valve spring what's stopping the valve from trying to come out towards the front of the gun therefore opening beyond what is necessary and possibly damaging the valve etc.? It looks like a stop needs to be put in to limit the valve opening when using a lighter spring. With the Impact a valve opening of .150'' was all that was necessary to get the 40fps gain. With some projectiles an opening of .100'' got the same velocity. Opening it to .200'' did nothing with the pressure used in the reg. which was 135bar. Question: How far should the valve open for max power? I realize that the stock RAW HM1000X doesn't have the adjustments that the Impact has. I was thinking that with the Huma reg. and the external plenum a gain of 50fps should be gained with not too much increase in reg. pressure. I was told the external plenum pictured should get me about a 30fps gain. I guess a lighter valve spring will be tried to see if it changes anything on the HM1000X.

Firstly, whal pellets are you shootings, you can get king heavies over 1000 in an old rapid so the bigger RAW should do that easily.

There are a few things to look at. Remove the hammer adjuster and pull out the spring, push the hammer forwards with a dowel, there should be about 5mm of travel as you compress the valve return spring. If there is less, the valve return spring is bottoming out.

Can you post a photo of the valve, the newer brass type give more power more easily but even these can be improved. The older valve has an o ring on the stem, if the valve is bashed open too far the the o ring is not in contact with the bore dumping air.

Air can be wasted if the probe is not sealing correctly, test that with a piece of tissues draped over the probe, take a shot, if the tissues moves you need to investigate the leak.

Make sure the barrel is in the correct orientation otherwise the transfer port in the block and barrel won’t align. Tighten all the location grub-screws firmly, doing the one neatest the block first.

Back the hammer cap all the way out, record the velocity, as you screw it in, the velocity should increase, if it doesn’t you are already over hitting the valve for that reg pressure.

can you post a photo of your hammer, on the end of the hammer is a pip, the length determines the amount of run up the hammer had before hitting the valve, the shorter the pip, the more run up,more velocity. A short pip with a weaker spring will give as much power as a long pip with a stronger spring but will be a lot easier to cock, feel nicer to shoot and won’t dump the air if the pressure drops low. Don’t make the pip too short or the trigger sear will over ride the hammer and smack into the cocking pin.

Another simple power fix, remove the valve location screw, drop a small o ring into the counterbore, replace the o ring and if stops any air wicking through.

I recommend you join the R7OC forum, Its a forum dedicated to rapids and RAWs, guys on there have been tuning rapids for years, plenty of good advice on there.

Bb

Upvote 0