You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HELP My raw is leaking!!

- Thread starter Jlacouturec

- Start date

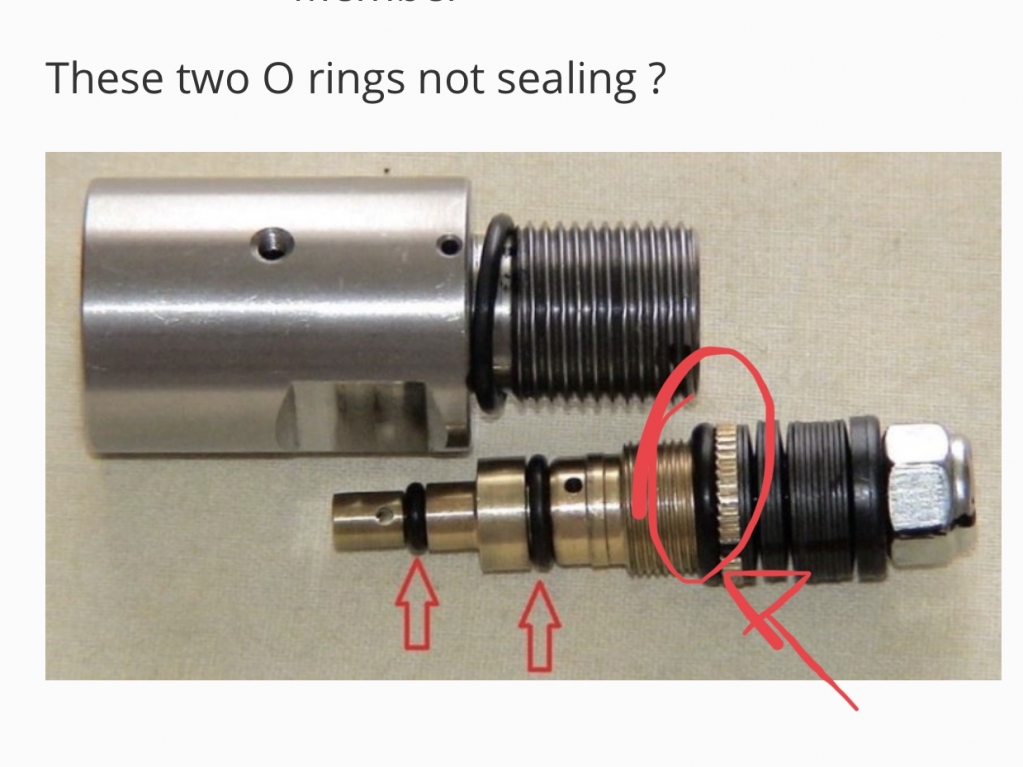

That is your atmospheric vent hole, when air leaks from that hole the o rings on your regulator need replaced. I zoomed in on your photo and can see the defective O ring.

t is the O ring right after the Belleville washers. Replace it and that will take care of leak. Other o rings might soon need replaced as well if your gun is close to 5 years old.

t is the O ring right after the Belleville washers. Replace it and that will take care of leak. Other o rings might soon need replaced as well if your gun is close to 5 years old.

Upvote 0

This oring was totally destroyed!!! Someone have the dimensions??? When i replace it i have to tighten it or simply until it adjust?

Upvote 0

It seems that the O ring pointed to in your picture is not among those sealing the air passages going to the vent hole where the leakage occurs so you may need to look further after replacing it.

Upvote 0

I have always been of the opinion, if you replace one replace them all, then make note of the sizes and when this service was done and keep it with the rifle or pistol

Upvote 0

Who came up with the order of the stack of those Belleville washers? Very unordinairy and non-linear stack...

Upvote 0

Who came up with the order of the stack of those Belleville washers? Very unordinairy and non-linear stack...

Exactly, that reg is set to run on pairs of washers, the multiple stack at the top are doing nothing other than making it more difficult to set up.

for most power levels they should be set ))(())(())(())[]. For higher reg pressure on large calibres )))((()))((([] more washers in the stack make for easier adjustment.

the two o rings on the core are the ones leaking, they need replacing, the one under the brass collar is merely a anti vibration locking device, it doesn’t matter if it’s mashed so long as you still have endfloat adjustment.

Bb

Upvote 0

- Regulator body: BS015 (14 x 1.78mm) – 1 off

- Regulator core: BS803 (6.35 x 1.78mm) – 1 off

- Regulator core: BS005 (2.57 x 1.78mm) – 1 off

- Regulator pin disc seal: BS804 (7.94 x 1.78mm) – 1 off

[/LIST=1]

All NBR70. Found the above sizes from Rapid MK-II service guide. It has exactly the same regulator as RAW.

Upvote 0

I just replaced them, can you tell me How much i have to tight the piston when I put it together again?

Upvote 0

Please elaborate which part do you want to know. In fact the screw and the hole to insert allen key are used to put required tension on the B washers.

The best way to find out, you should know that what should be the reg pressure of your gun.

Then you can remove the big screw under the action and put a pressure guage there. Then put the regulator in the action and fill the gun.

If your RAW is 60 ftlb model then your reg pressure should be ideally between 150 bar and 155 bar.

Normally 152 bars works great.

I hope this helps.

Umair Bhaur

The best way to find out, you should know that what should be the reg pressure of your gun.

Then you can remove the big screw under the action and put a pressure guage there. Then put the regulator in the action and fill the gun.

If your RAW is 60 ftlb model then your reg pressure should be ideally between 150 bar and 155 bar.

Normally 152 bars works great.

I hope this helps.

Umair Bhaur

Upvote 0

I just replaced them, can you tell me How much i have to tight the piston when I put it together again?

Without a reg tester it’s trial and error. You need to adjust the endfloat first, remove the stack washers push in the reg core, screw in the brass adjuster until the compression oring starts to take up slack, now push and pull the reg core there should be about 0.5mm back and forth movement, screw in the brass adjuster until you achieve that. Now rebuild the stack of washers in the configuration outlined above, with an Allen key in the core, and a spanner sure on the nut.

without a reg tester or a gauge on the block you will have to keep tweaking the pressure until you get the speed you after.

Bb

Upvote 0