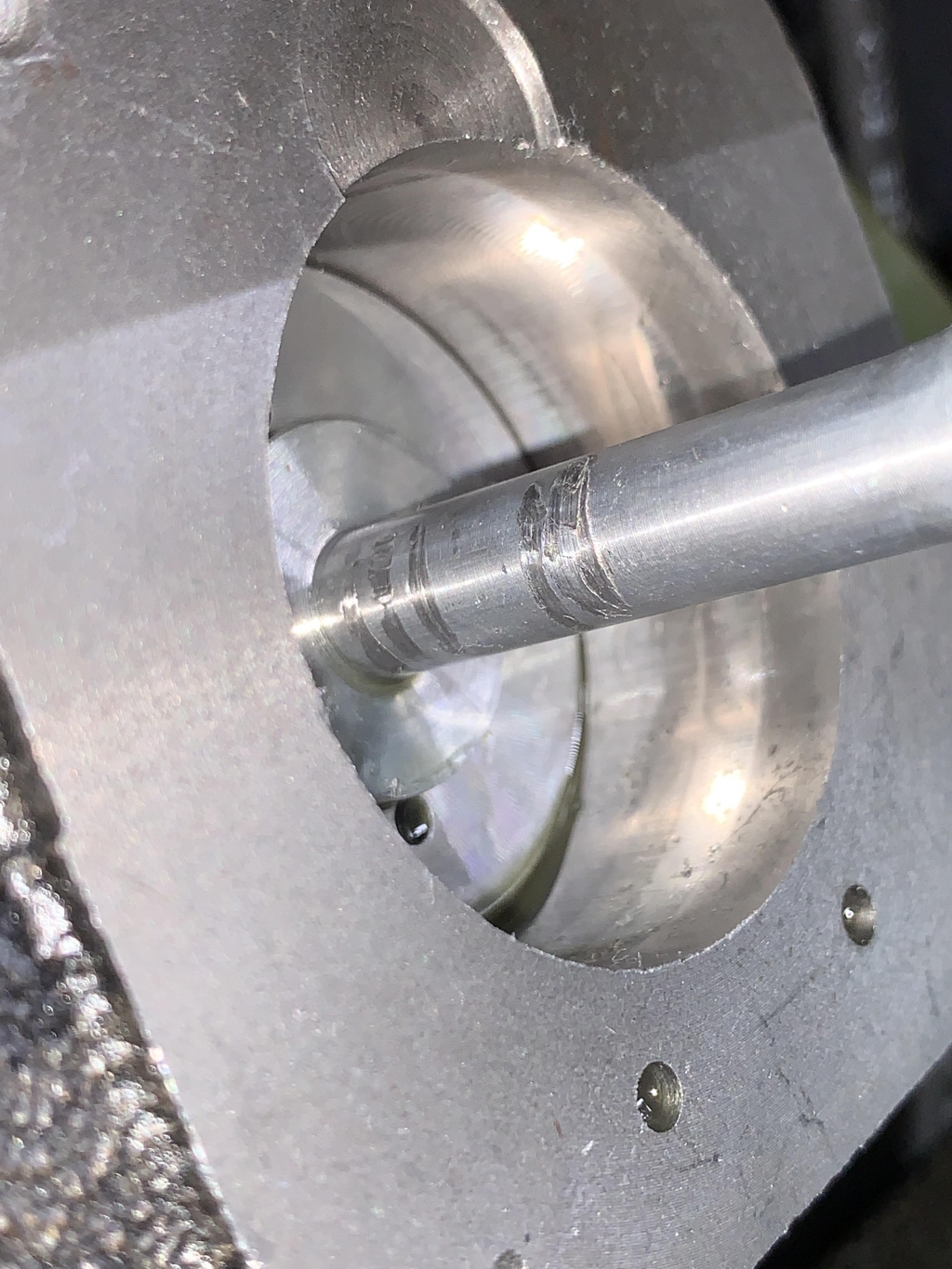

Okay, here are the promised pictures. I’ll post them first. Then I need some input. Below are the replacement piston seals that were included in the rebuild kit sent with the Lightning compressor. Then a picture of the existing seals on the piston. Also, take note of the one picture of the piston rod itself. Not sure if this is a problem, but doesn’t look right. The piston is scarred up, it is below the seals but it is rough.

Now for the problem. So I redid the head and put the replacement gasket on and the O-rings as before. I started the compressor and it was building pressure really well, then stopped increasing around 3000 psi. Run a long time without increasing so I shut it down, kept the pressure in the system and checked for leaks again. I found a small one and thought now I got it. Started to fill my bottle and it was working fine but stopped building pressure again at 4000 psi. I shut it down again and went over everything one more time. Found a very small leak on the bottle gage. Honestly, I had not checked it before. Was checking everything without the bottle I was trying to fill. Anyway, 1st question, couldn’t get it to stop leaking so I took it about. I realized then that they had used some kind of sealant on the threads. I don’t know what they used and didn’t have anything but teflon tape. So I used it, knowing I saw somewhere that you shouldn’t. My question is why no teflon tape? I figured it was only temporary so I would see if it helped and it did the leak stopped.

So I tried to fill the bottle the rest of the way to 4500. However, this time it stopped at 2000 psi and would go higher and then I noticed that the pressure was back in the coolant reservoir. So I tore it down again and found this

The new gasket I had just put in was already chewed up. It hadn’t been in use for an hour. The original gasket lasted just over a year (but really about 7 hours). This one didn’t make it an hour. So now I am stumped. Either the gasket is complete garbage (but why was the first one able to last so long) or something has changed and the gasket is being damaged by the action of the piston. I did notice this part was just sitting on the end of the piston rod

I don’t know if maybe it is moving around and damaging the o-ring (maybe the o-rings don’t fit properly, but seemed to be right when I installed it) But the 0-ring was damaged to the point that air pressure was escaping into the coolant as described before. Below is another picture of the damaged 0-ring and the last of the repair kit replacements. The second (one on top of the other) is an attempt to show how much it has been stretched.

Thought I would go to hardware store tomorrow and find a different 0-ring to try, then I could find some where online to buy replacements. Where do you all recommend getting the replacements. If the original green ones are junk that may fix it, but if there is something else causing the damage, I’m not going to get far without replacing these things “often”. I think someone recommended a specific type of o-ring, that may help. I thought I would try one from the hardware store, that should let me know at least if the green ones are just no good. I didn’t take the head clear off because I didn’t want to damage the gasket. Anyway, I’m looking for suggestions.

I’m not sure when I will get back to this, maybe tomorrow morning but I will have to leave town later in the day and wont get back to it until later in the week, maybe Wednesday.

Thanks

Frustrated rgwv