My goal each day is to spend at least four hours on anything PCP related, and today was maintenance day on my compressor. This is the first fluid drain and refill since I bought it new in July of 2018.

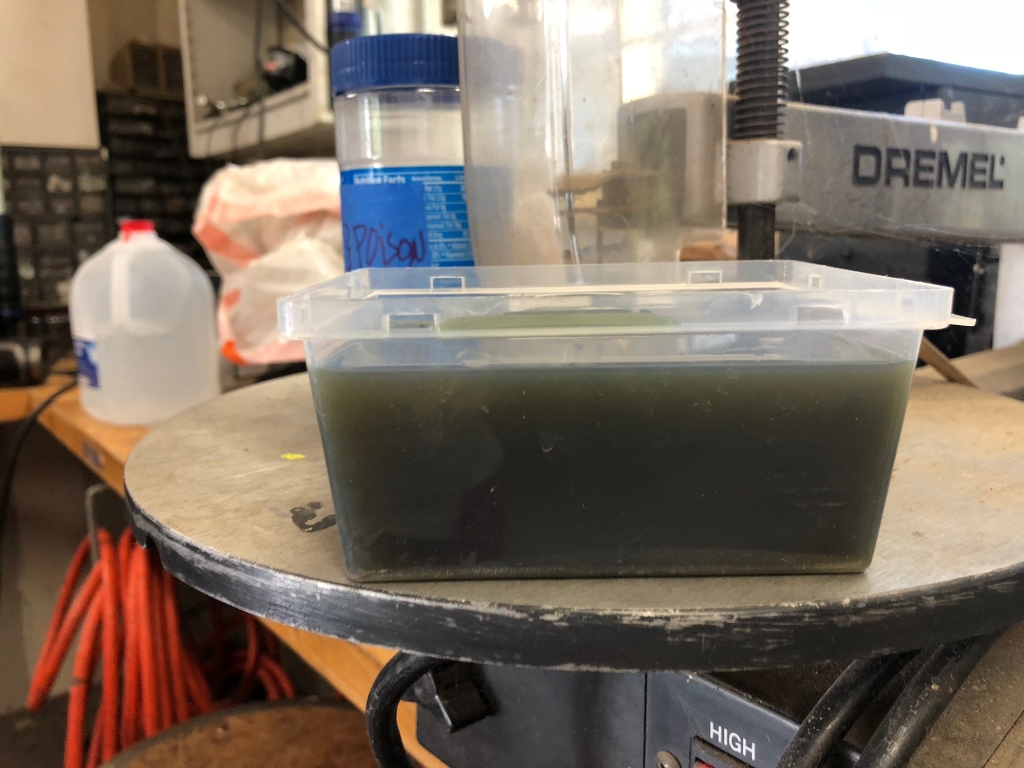

First order was the compressor oil drain. With a total of 4 hours use in a year, the oil doesn’t look bad at all. I never once did an initial fill and drain to get rid of factory assembly crud, either. This is the original 13.5 ounce of oil from a year ago.

A bit bit of Nylog Red on the drain plug threads and it’s all buttoned up. This time it only took 12.5 ounces to the fill line, instead of the original 1.5 ounces.

First order was the compressor oil drain. With a total of 4 hours use in a year, the oil doesn’t look bad at all. I never once did an initial fill and drain to get rid of factory assembly crud, either. This is the original 13.5 ounce of oil from a year ago.

A bit bit of Nylog Red on the drain plug threads and it’s all buttoned up. This time it only took 12.5 ounces to the fill line, instead of the original 1.5 ounces.