Last update (finally):

And there was room for a couple of knife handles from the walnut also.

Udate 9:

Polishing. First round. 3 more to go, and then the job is done and the stocks are ready for (the) action.

Update 8:

Last oil layer is done. Polishing next. Some small detail picks:

Update 7:

Working in the first layers of oil with the 000 steel wool.

Update 6:

Ready for oil treatment.

Update 5:

Fine sanding. First round before light water treatment a couple of times to rise the wood. Some leftovers from the walnut gives room for a couple of knives also

Update 4:

forming and sanding the grip on the cherry wood stock:

Update 3:

Finished bedding. Starting from outside. The Turkish walnut is HARD to work with!

Update 2:

soon ready for the «outside work», but some adjustments on both stocks needed before I can start that.

Update 1:

Then easter holiday struck in, and I have to put the project on hold for over a week.

Carving job on the cherry stock almost done.

Carving job on the cherry stock almost done.

@@@@@@@@@@@@@@@@@@@@@

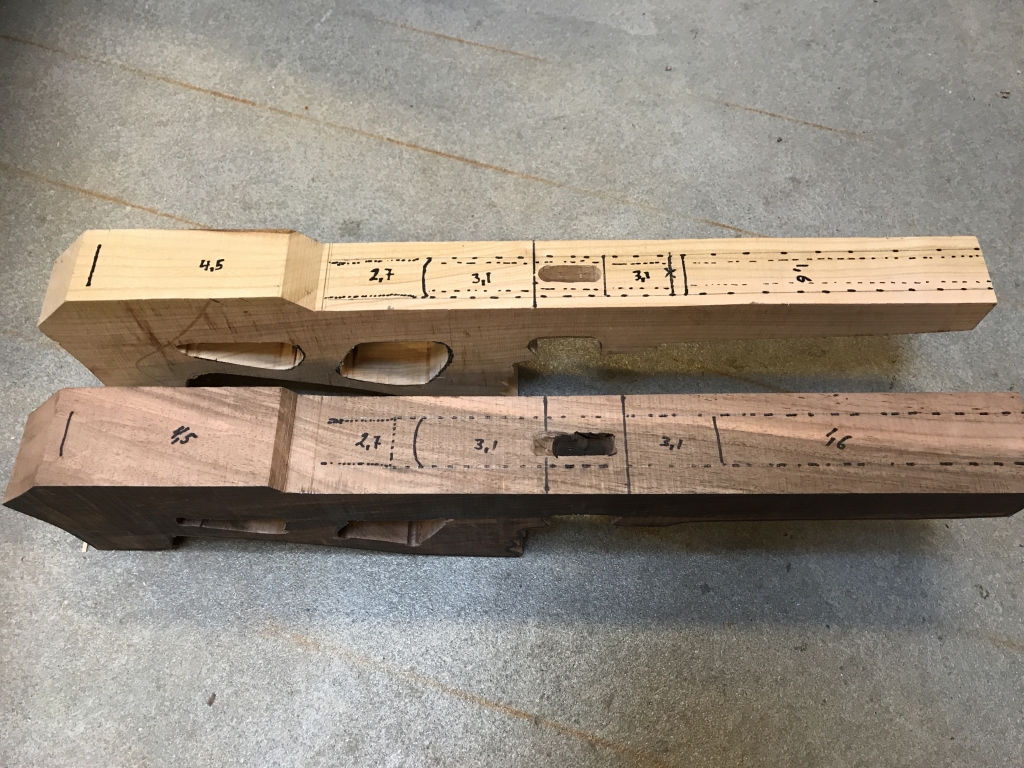

Some of you may remember my first attemt to make a stock for my Wildcat a few years back, from flame birch. Some of the AGN members have pm`d me, and asked if I could make one for them, but I have been a bit skeptical to that. However, for some time now I have felt the urge to make another, and from what I have heard, is the new wildcat stock exactly similar to the old, so I will give it a try, using my 1.gen wildcat action as a base. Two Stocks. One in Cherry Wood, and one in Turkish Walnut. (Especially the walnut material was pricy, so if the project goes down the drain, my plan is to cut it up for knife handles).

So...….. I thought I could update this thread with the ongoing prosess, starting with a pictured of the materials. One of the pictures states where I am now in the prosess, and the old birch-stock saying where I want to end up. More pictures to come, and hopefully it can be an inspiration for others DIY-members. No advanced tools required, other then what you will see in this thread.

And there was room for a couple of knife handles from the walnut also.

Udate 9:

Polishing. First round. 3 more to go, and then the job is done and the stocks are ready for (the) action.

Update 8:

Last oil layer is done. Polishing next. Some small detail picks:

Update 7:

Working in the first layers of oil with the 000 steel wool.

Update 6:

Ready for oil treatment.

Update 5:

Fine sanding. First round before light water treatment a couple of times to rise the wood. Some leftovers from the walnut gives room for a couple of knives also

Update 4:

forming and sanding the grip on the cherry wood stock:

Update 3:

Finished bedding. Starting from outside. The Turkish walnut is HARD to work with!

Update 2:

soon ready for the «outside work», but some adjustments on both stocks needed before I can start that.

Update 1:

Then easter holiday struck in, and I have to put the project on hold for over a week.

@@@@@@@@@@@@@@@@@@@@@

Some of you may remember my first attemt to make a stock for my Wildcat a few years back, from flame birch. Some of the AGN members have pm`d me, and asked if I could make one for them, but I have been a bit skeptical to that. However, for some time now I have felt the urge to make another, and from what I have heard, is the new wildcat stock exactly similar to the old, so I will give it a try, using my 1.gen wildcat action as a base. Two Stocks. One in Cherry Wood, and one in Turkish Walnut. (Especially the walnut material was pricy, so if the project goes down the drain, my plan is to cut it up for knife handles).

So...….. I thought I could update this thread with the ongoing prosess, starting with a pictured of the materials. One of the pictures states where I am now in the prosess, and the old birch-stock saying where I want to end up. More pictures to come, and hopefully it can be an inspiration for others DIY-members. No advanced tools required, other then what you will see in this thread.