Question below...but read this first:

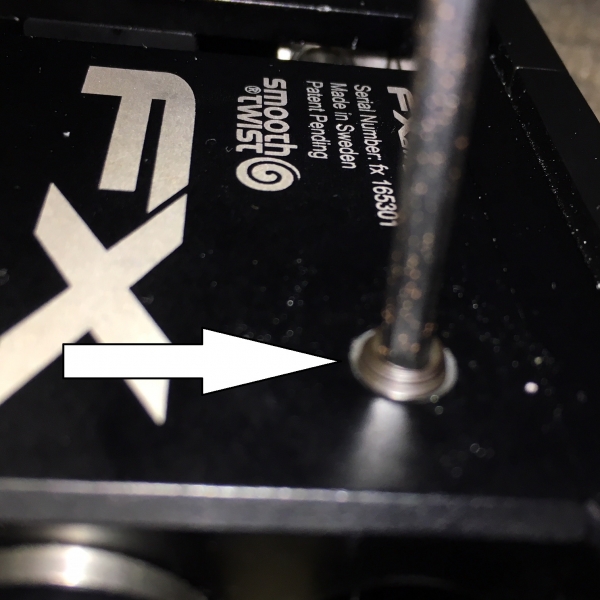

I have an FX Impact with the thumb-dial grub-screw securing the barrel on the right side frame (see photo). From other AGN threads I learned that the new Impacts now have a grub-screw that is recessed inside that same thread. The thumb-dial screw is gone, instead FX uses a hex screw to secure the barrel through the same existing hole in the right side frame. The screw grubs the barrel by seating inside a dimple on the barrel. So I went to Home Depot and purchased an M6 x 6mm hex screw. This supposed to help with the original thumb-dial screw loosening in some cases ( I never had that issue).

This setup is fine, albeit as in the attached video Ernest Rowe describes too much pressure by the grub screw could push the barrel to one side and may cause misalignment. The reason for the misalignment is the possible over-compression of the barrel supporting o-rings which "float" the barrel in several places. This could move the aim-point.

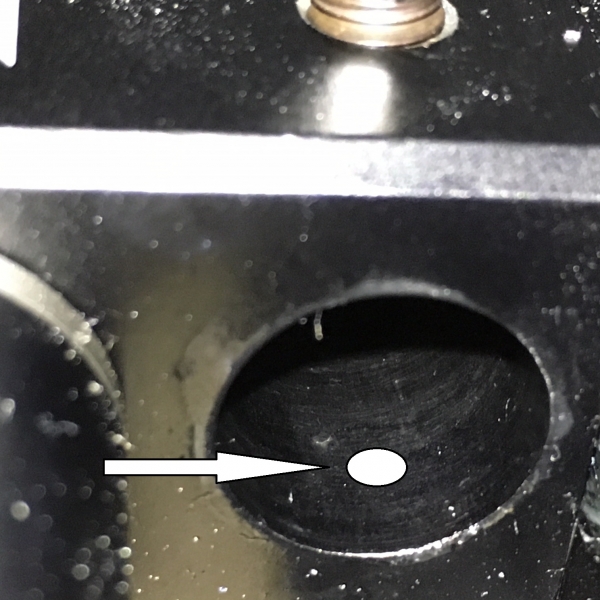

I found out the new X-twist barrels (at least my 700mm X-Twist .25) do NOT have any dimples anymore. The grub-screw supposed to be tightened against the barrel as the single point of contact holding the barrel from sliding. My understanding is that the FX Crown has two grub screws (no barrel dimples). I am concerned about this single contact point requiring more pressure than with the dimple. This extra pressure by the screw may cause a barrel misalignment that could throw off the aim-point.

So, what I was wondering...add an identical grub-screw exactly the opposite side of the existing one? (to the left side also)

The two opposing grub screws would not only help secure the barrel better from sliding, but also would ensure that the barrel is not misaligned by over-tightening the single right-side grub screw.

I am not a machinist, nor do I have any special equipment...but (correct me if I am wrong) should be able to add the opposite grub screw this way :

1. Remove the left side "shield"

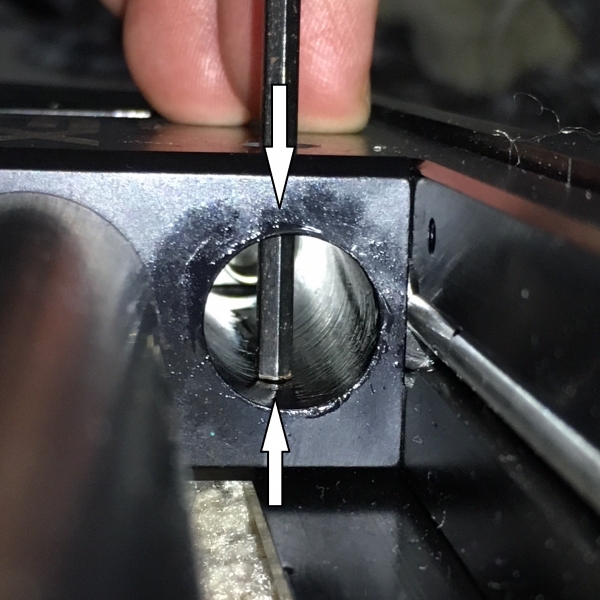

2. Drill a pilot hole though the existing right -side hole (using it as a guide) in to the opposite side --- see the wrench in the photo

3. Finish drilling out the hole on the left side from the outside

4. Tap an M6 size thread in the left side hole just created

5. Cut out a small hole in the shield just over the new screw-hole and remount the shield

.

.

.

Ernest Rowe's videos on alignment issues:

.

.

I have an FX Impact with the thumb-dial grub-screw securing the barrel on the right side frame (see photo). From other AGN threads I learned that the new Impacts now have a grub-screw that is recessed inside that same thread. The thumb-dial screw is gone, instead FX uses a hex screw to secure the barrel through the same existing hole in the right side frame. The screw grubs the barrel by seating inside a dimple on the barrel. So I went to Home Depot and purchased an M6 x 6mm hex screw. This supposed to help with the original thumb-dial screw loosening in some cases ( I never had that issue).

This setup is fine, albeit as in the attached video Ernest Rowe describes too much pressure by the grub screw could push the barrel to one side and may cause misalignment. The reason for the misalignment is the possible over-compression of the barrel supporting o-rings which "float" the barrel in several places. This could move the aim-point.

I found out the new X-twist barrels (at least my 700mm X-Twist .25) do NOT have any dimples anymore. The grub-screw supposed to be tightened against the barrel as the single point of contact holding the barrel from sliding. My understanding is that the FX Crown has two grub screws (no barrel dimples). I am concerned about this single contact point requiring more pressure than with the dimple. This extra pressure by the screw may cause a barrel misalignment that could throw off the aim-point.

So, what I was wondering...add an identical grub-screw exactly the opposite side of the existing one? (to the left side also)

The two opposing grub screws would not only help secure the barrel better from sliding, but also would ensure that the barrel is not misaligned by over-tightening the single right-side grub screw.

I am not a machinist, nor do I have any special equipment...but (correct me if I am wrong) should be able to add the opposite grub screw this way :

1. Remove the left side "shield"

2. Drill a pilot hole though the existing right -side hole (using it as a guide) in to the opposite side --- see the wrench in the photo

3. Finish drilling out the hole on the left side from the outside

4. Tap an M6 size thread in the left side hole just created

5. Cut out a small hole in the shield just over the new screw-hole and remount the shield

.

.

.

Ernest Rowe's videos on alignment issues:

.