Killer, ima get one

Mine is supposed to ship this Friday.

Any updatet ? With only adding this plenum ? To mk2

Mine has not shipped yet, not much communication on the seller's part unfortunately.

Upvote 0

Killer, ima get one

Mine is supposed to ship this Friday.

Any updatet ? With only adding this plenum ? To mk2

Mine should be shipped 1st of September. Hopefully I get it in time.

I achieved the same fps at 10 bars less. No significant changes with the new housing and plenum of mk2.

@panisd yup is about that much 10% more power (not really much) specially if you have the 1st gen Mk2, latest mk2 has a bigger integrated valve, so is a BIG difference.

@mtnGhost Duro90 bumpers fails 100% of the time shooting .022 + cal IME (specially powered ones) is the first thing I took out from my MK 1 1/2 (not sure now if MKII was the right name for early release). Even Nylon is better. And since is harder, do not cushion that much, ergo more power, like 5 to 10 more fps.

How do we know if its first gn mk2 or second

first time i hear that there is version 1 mk2 and verson 2 !!

Mine should be shipped 1st of September. Hopefully I get it in time.

Does he respond to your emails? He said he would ship mine by the end of last week but I haven't received a tracking number or any other communication. Maybe he's just busy.

I haven't contacted him after the purchase. Hopefully he's busy perfecting those plenums.

How do we know if its first gn mk2 or second

first time i hear that there is version 1 mk2 and verson 2 !!

The only difference is the valve housing has a larger and integrated valve seat. In other words the valve seat is cut directly into the valve housing rather than being a separate part. FX could tell you a starting serial number but they're not good at responding to customer's questions.

Just tested different reg pressures. At 150 bars, my average is 920. At 160 bars its shooting at an average of 943 and at 170bars its shooting at 975ish.

I have got the mk2 parts from fx i am sure that will help alot.

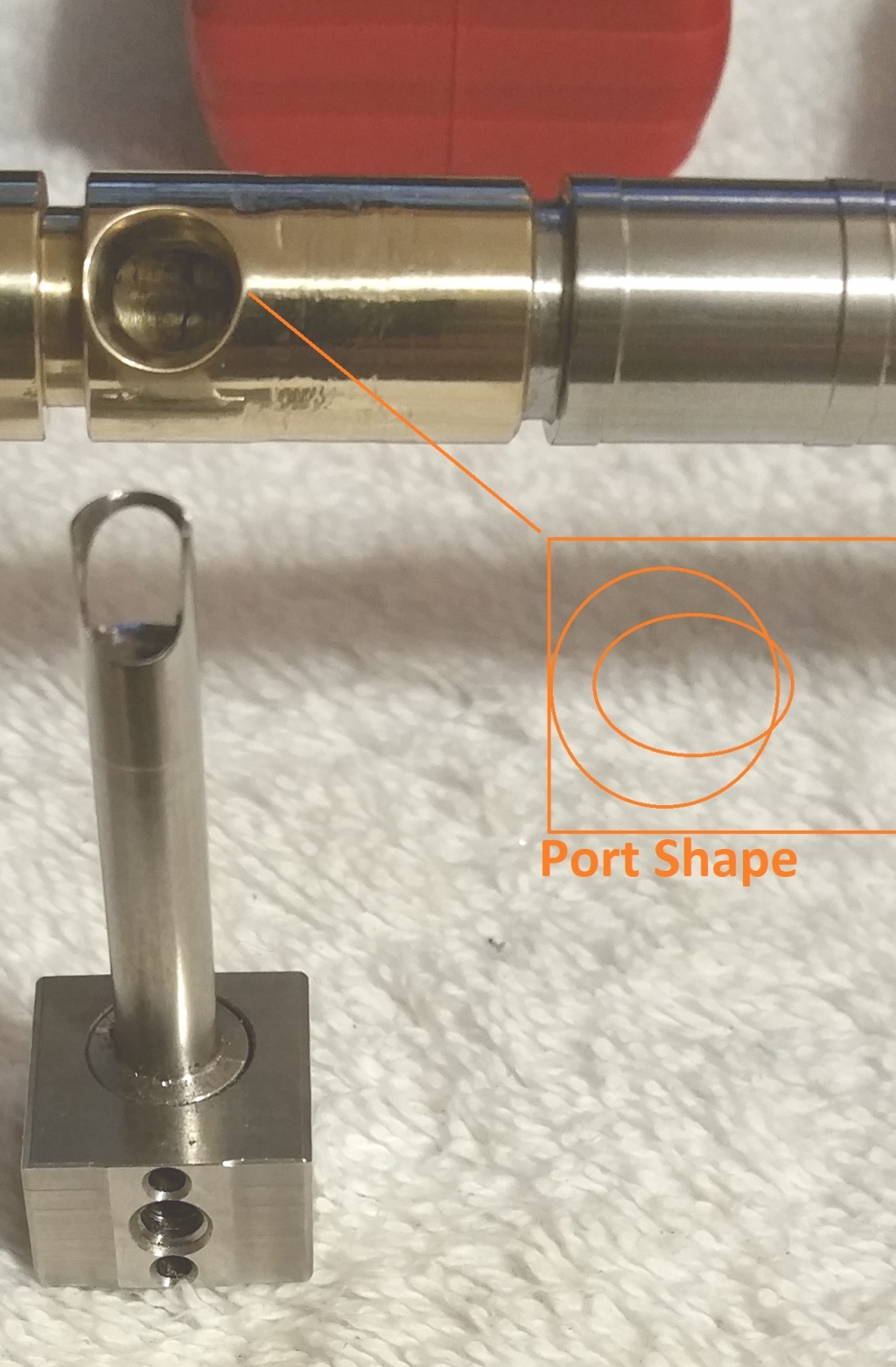

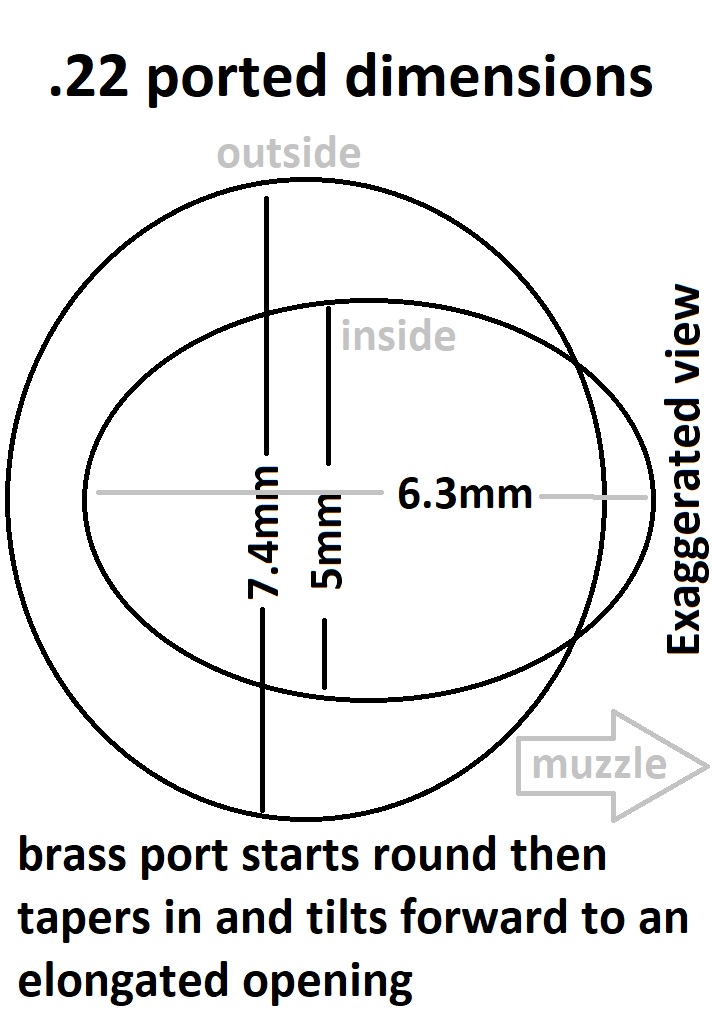

Ok but I believe you can get this speed under 140 bar. Here is a picture and drawing of the modified port if you need it. It's best to cut with a 1/8" carbide burr in your rotary tool then switch to something less aggressive to finish and polish. You don't have to take the top off the probe but it helps. A 7mm port feeds the brass one so you want the brass opening a little larger. You should not be able to see the pellet probe edges through the brass port. These dimensions work well for me.

I’ve sent him an email too a couple of days ago but no response yet so I haven’t had the chance to place an order. He might be quite busy I presume. I’ve checked on his webpage, it looks like he’s quite an expert modifying and tuning airguns. Let’s just hope he gets back to us soon.

I’m waiting for a valve kit that Edosan sent me a couple of weeks ago. I will start with the upgrades on my Impact X Gen 2 as soon as this kit arrives. Delrin C3, hammer weight and 6.5mm VS. Then I will do porting on both pellet (slugs) probe and brass TP.

Regarding the brass TP I’ve seen that ER does it in a different way. He rather prefer just to elongate the TP starting at the breach end, just were the o-ring groove begins and then he goes up to 7mm towards the muzzle end. Then he elongates the pellet probe too but going backwards and not cutting it in a half moon shape. There are quite a few videos and pics on his Instagram account. I’m not quite sure on which way to go. Any thoughts?

Thanks in advance

I’ve sent him an email too a couple of days ago but no response yet so I haven’t had the chance to place an order. He might be quite busy I presume. I’ve checked on his webpage, it looks like he’s quite an expert modifying and tuning airguns. Let’s just hope he gets back to us soon.

I’m waiting for a valve kit that Edosan sent me a couple of weeks ago. I will start with the upgrades on my Impact X Gen 2 as soon as this kit arrives. Delrin C3, hammer weight and 6.5mm VS. Then I will do porting on both pellet (slugs) probe and brass TP.

Regarding the brass TP I’ve seen that ER does it in a different way. He rather prefer just to elongate the TP starting at the breach end, just were the o-ring groove begins and then he goes up to 7mm towards the muzzle end. Then he elongates the pellet probe too but going backwards and not cutting it in a half moon shape. There are quite a few videos and pics on his Instagram account. I’m not quite sure on which way to go. Any thoughts?

Thanks in advance

The best possibility is a full bore sized transition from the transfer port into the bore. Removing the top of the probe gets you closer.

Today I have tested again mk1 VH and Plenum VS mk2 VH and Plenum. Since I measure it in mps here some results ...

Mk1 setup 145bar JSB heavy mk2 33.95gr ... 285ms

Mk2 setup 145bar JSB heavy mk2 33.95 gr ... 318ms

Also tomorow will test new ext plenum 45cc in 0.8mm Toray carbon wrapped Al body ... looks nice

Thanks for the quick response.

I would like to say thank you to Edosan for starting this incredible thread. I just can’t remember of any thread that has been so helpful, informative and productive than this one. Of course I would like to say thank you to all the participants that have contributed with their experiences and thoughts. Its really impressive how much I’ve learnt in the last couple of months. Keep up with the good work folks!!!

Today I have tested again mk1 VH and Plenum VS mk2 VH and Plenum. Since I measure it in mps here some results ...

Mk1 setup 145bar JSB heavy mk2 33.95gr ... 285ms

Mk2 setup 145bar JSB heavy mk2 33.95 gr ... 318ms

Also tomorow will test new ext plenum 45cc in 0.8mm Toray carbon wrapped Al body ... looks nice

Can you test the .22 calibre as well. That would be really helpful