I got an idea last night, i was thinking how i could make a barrel suport for my impact.

what if i could make the A13 barrel suport with treads so the shroud was screwed on to instead of the endcap

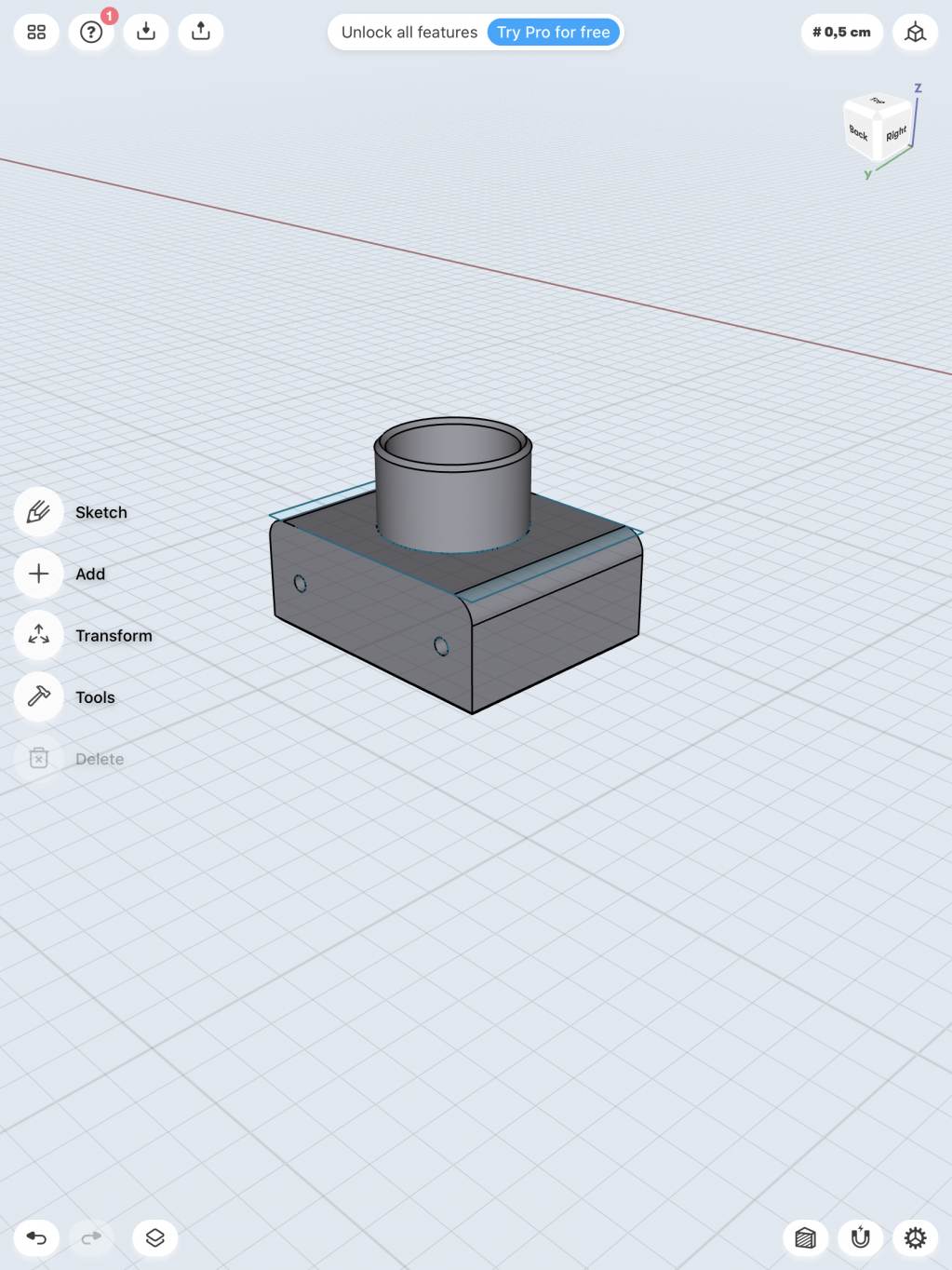

her is a quick scetch

what do you guys think? Would it work?

what if i could make the A13 barrel suport with treads so the shroud was screwed on to instead of the endcap

her is a quick scetch

what do you guys think? Would it work?